Large-sized static mixer

A static mixer, a large-scale technology, applied in the direction of fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of increasing the processing difficulty of the mixing unit, reducing the flow section of the mixer, and reducing the mixing efficiency of the mixer. Achieve the effect of superior market competitiveness, low manufacturing cost and superior mixing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] First of all, it should be noted that the orientation concepts such as left, right, up, down, front, and rear are cited in this manual, which are only for the convenience of describing the orientation and orientation of each component. They are a relative orientation expression and do not affect the product. actual installation position.

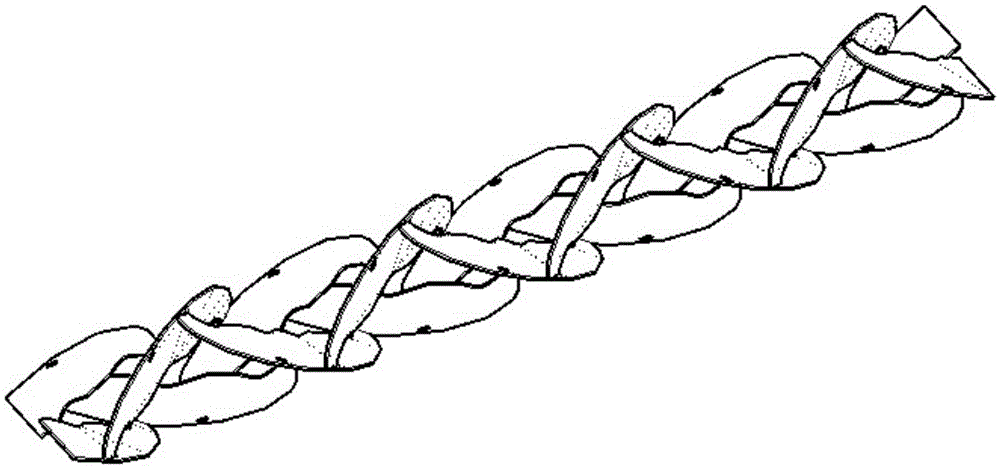

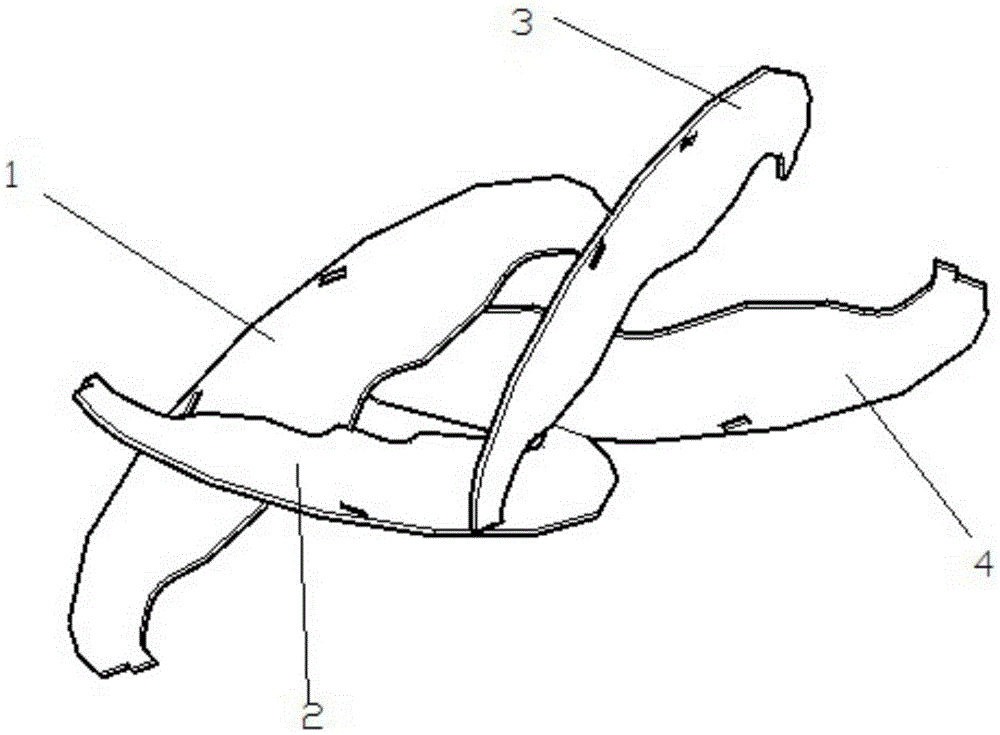

[0034] see figure 1 with figure 2 , this embodiment discloses a large-scale static mixer, which includes a pipe and at least one mixing unit placed in the pipe, and the two ends of the pipe are open; the mixing unit includes four arc-shaped first Blade 1, second blade 2, third blade 3, and fourth blade 4; the first blade 1 and the second blade 2 are relatively intersected, and the axis of the intersection point is horizontal. The first blade 1 is arranged on the left side, and the second blade 2 is located on the right side, the first blade 1 is angled downward around the axis of the intersection point, and the second blade 2 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com