Full-automatic gluten separating machine

A gluten machine, fully automatic technology, used in metal processing, food forming, food science and other directions, can solve the problems of affecting work efficiency, unsanitary, low efficiency, etc., to eliminate direct contact, reduce labor costs, and improve hygiene. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

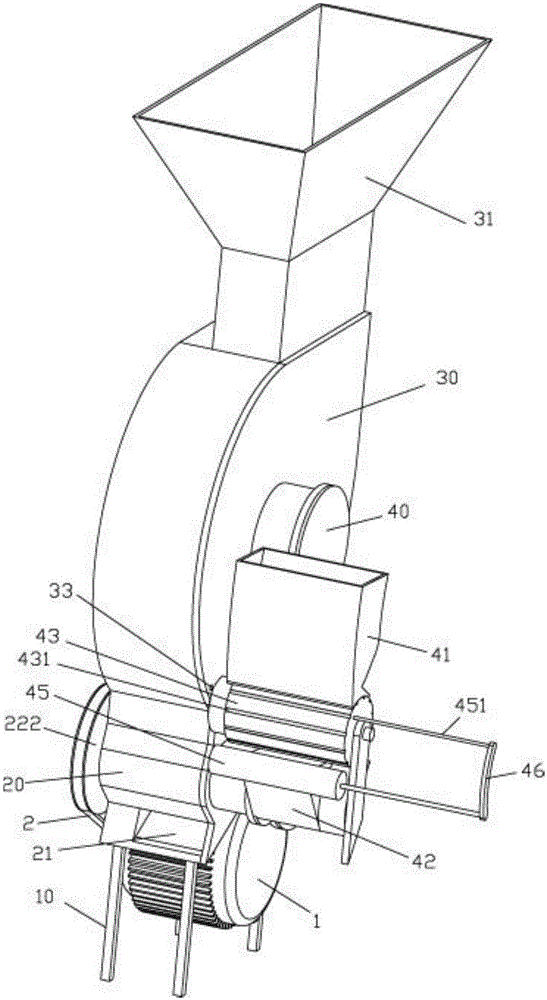

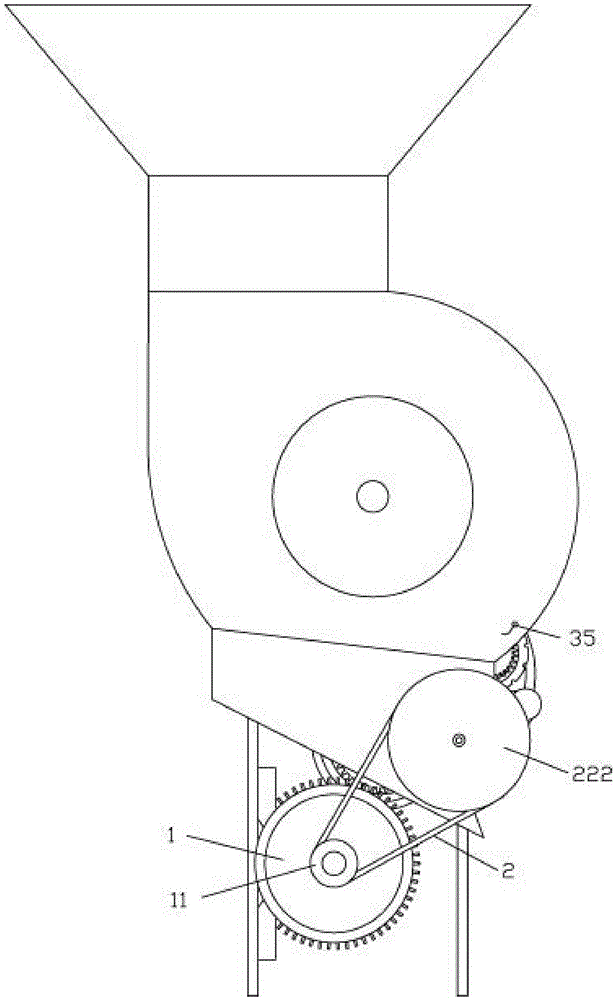

[0027] Examples, see e.g. Figure 1 to Figure 10 As shown, a fully automatic gluten machine comprises a frame 10, a cutting box 20 is fixed on the top of the frame 10, a feeding box 30 is fixed on the top of the cutting box 20, and the cutting box 20 and the feeding The casing 30 communicates up and down, and the top of the feeding casing 30 is fixed with a feeding nozzle 31. A main turntable 32 is arranged in the feeding casing 30. The walls are close to each other, and a plurality of discharge grooves 321 are evenly distributed on the side wall of the main turntable 32. There is a discharge port 21 on the left side of the cutting box 20, and the cutting box 20 above the discharge port 21 is hinged. There is a cutting shaft 22, a spiral cutter 221 is fixed on the cutting shaft 22, and a blanking guide plate 23 is arranged above and below the spiral cutter 221, and the blanking guide plate 23 above the spiral cutter 221 is positioned at the center of the main rotating disk 32....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com