Clear oil hotpot seasoning and making method thereof

The technology of a hot pot base material and a production method, which is applied in the field of seasoning food, can solve the problems of not meeting the health needs of modern people, high fat content, easy adhesion of hot pot, etc., and achieves moderate spiciness, stable product quality, and not easy to get angry. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0051] Calculated according to frying 100 grams of clear oil hot pot bottom material, including the following raw materials: 40 grams of soybean oil, 45.75 grams of rapeseed oil, 4 grams of glutinous rice cake chili, 1 gram of ginger, 6 grams of watercress, 0.5 grams of green pepper powder, white Kou powder 0.08g, 0.1g star anise powder, 0.1g grass fruit powder, 0.2g cumin powder, 0.1g amomum powder, 1g white wine, 0.25g monosodium glutamate, 0.27g chili red, 0.4g cooked spicy oil and 0.25g chili essential oil .

[0052] (1) Material selection: select the above-mentioned raw materials, select raw materials without moths, mildew, peculiar smell, pollution, and impurities, and keep them with the proper color, natural aroma or spicy taste of the raw materials. Control the moisture content of the original dry raw material to not exceed 12wt% and the total ash content to not exceed 8wt%.

[0053] (2) Raw material preparation: Prepare the above-mentioned required raw materials and ...

example 2

[0066] Calculated according to frying 100 grams of clear oil hot pot bottom material, including the following raw materials: 37 grams of soybean oil, 46 grams of rapeseed oil, 5 grams of glutinous rice cake pepper, 2 grams of ginger, 5 grams of watercress, 1 gram of green pepper powder, 0.05 grams of white powder 0.05 grams of star anise powder, 0.2 grams of grass fruit powder, 0.1 grams of cumin powder, 0.2 grams of Amomum powder, 2 grams of white wine, 0.4 grams of monosodium glutamate, 0.4 grams of red pepper, 0.3 grams of cooked spicy oil and 0.3 grams of pepper essential oil.

[0067] In this example, the preparation method of the clear oil hot pot bottom material is the same as that of Example 1.

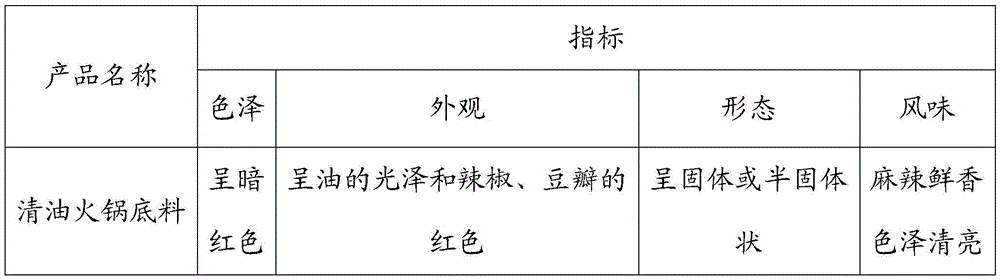

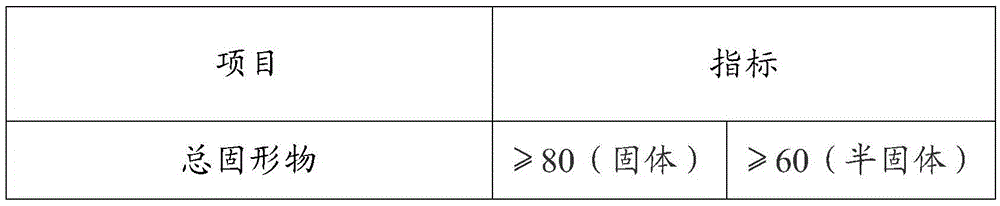

[0068] The clear oil hot pot bottom material prepared by this example can meet the requirements of each index in Table 1 to Table 3.

[0069] The clear oil hot pot bottom material and its production method of the present invention further improve the production process of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com