Pneumatic tipping machine

A tipping machine and dynamic mechanism technology, applied in the direction of dough extruder, dough forming and cutting equipment, etc., can solve the problems of low efficiency and complex structure, and achieve the effect of simple overall structure, improved production efficiency and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

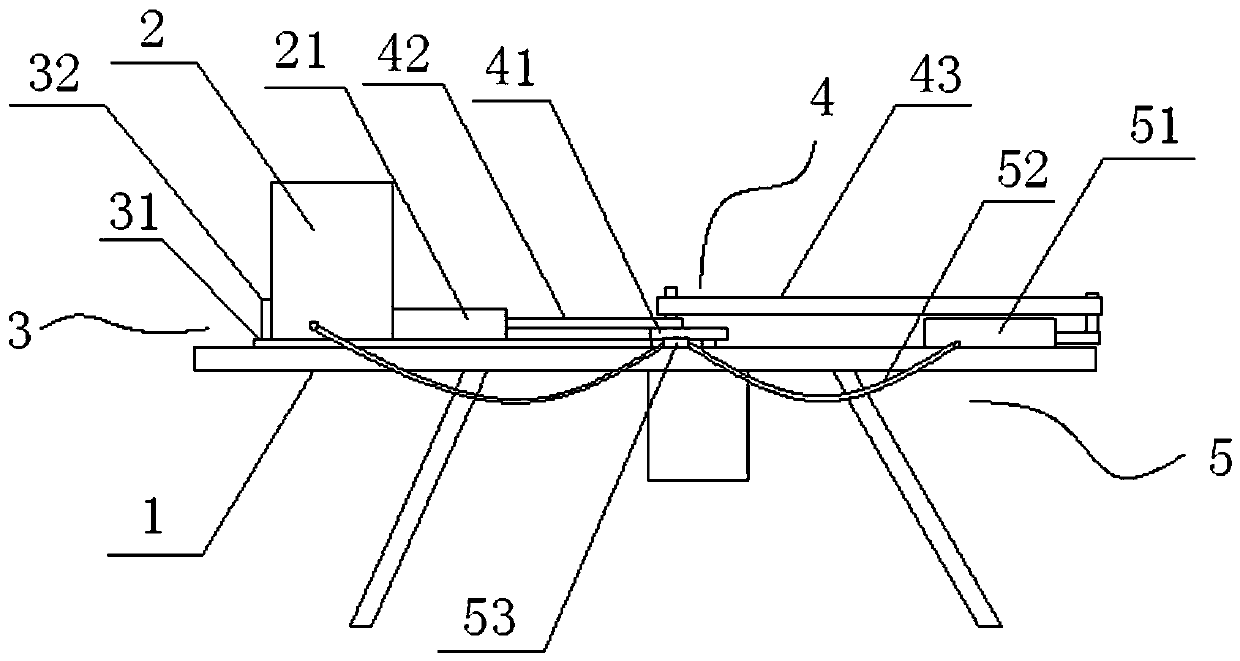

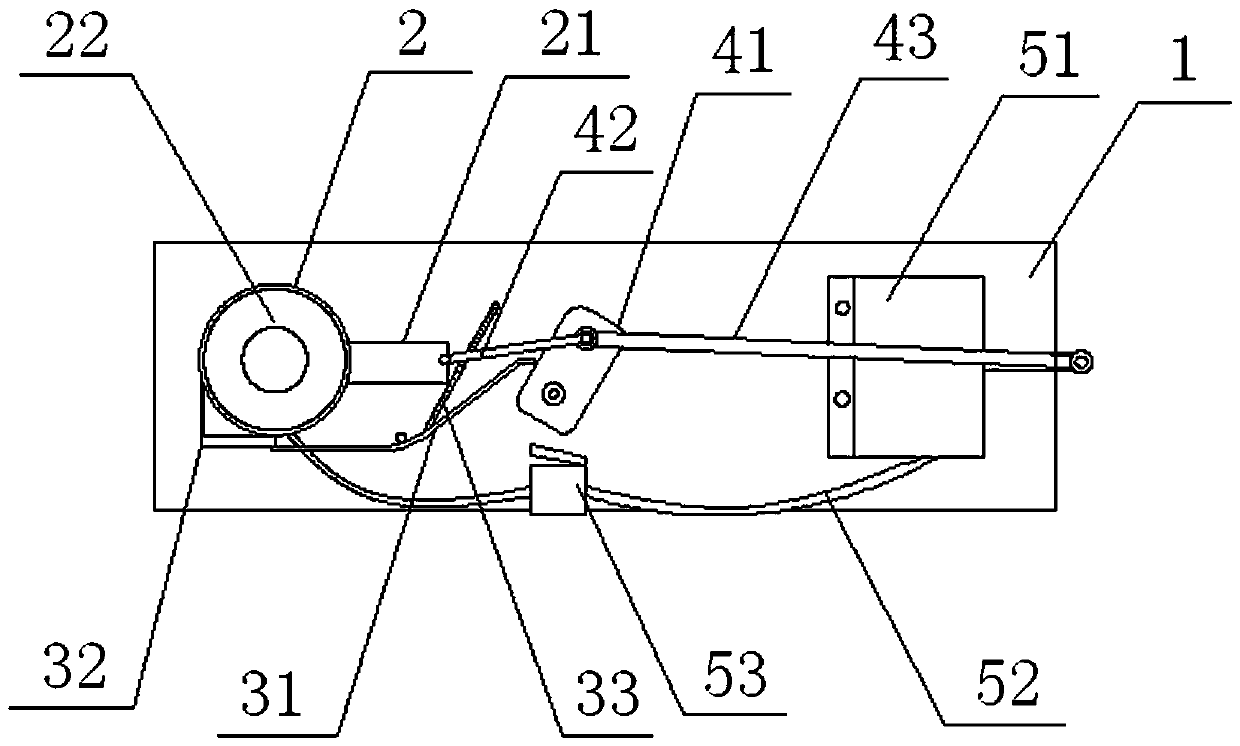

[0016] Example 1, such as figure 1 A pneumatic tipping machine shown includes a frame 1 , a noodle cylinder 2 , a noodle cutting mechanism 3 , a biasing mechanism 4 and a pneumatic mechanism 5 . The working process of the pneumatic tipping machine is: put soft dough in the dough cylinder, start the deflection mechanism, the eccentric rocker arm 42 on the deflection shaft of the deflection block 41 on the motor shaft of the deflection mechanism 4 drives the pressure rod 21 to pass through The hole reciprocates, the eccentric pressure rod 43 on the deflection shaft drives the piston rod of the cylinder 51 to perform telescopic movement, and the eccentric rocker arm 42 drives the pressure rod 21 to form an extrusion chamber with the help of the retaining edge 22 in the surface cylinder and the surface drain on the surface cylinder At this time, the eccentric pressure rod 43 drives the piston rod to supply air to the extrusion chamber through the air pipe 52, and the eccentric blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com