Six-phase static sealing high-temperature superconducting motor

A high-temperature superconducting, static technology, applied in the shape/style/structure of electrical components, electromechanical devices, winding conductors, etc., can solve the problems of increasing the operating cost of high-temperature superconducting motors, increasing the difficulty of power converter control, and being expensive. , to achieve the effect of simple structure, good cooling effect and high operation reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

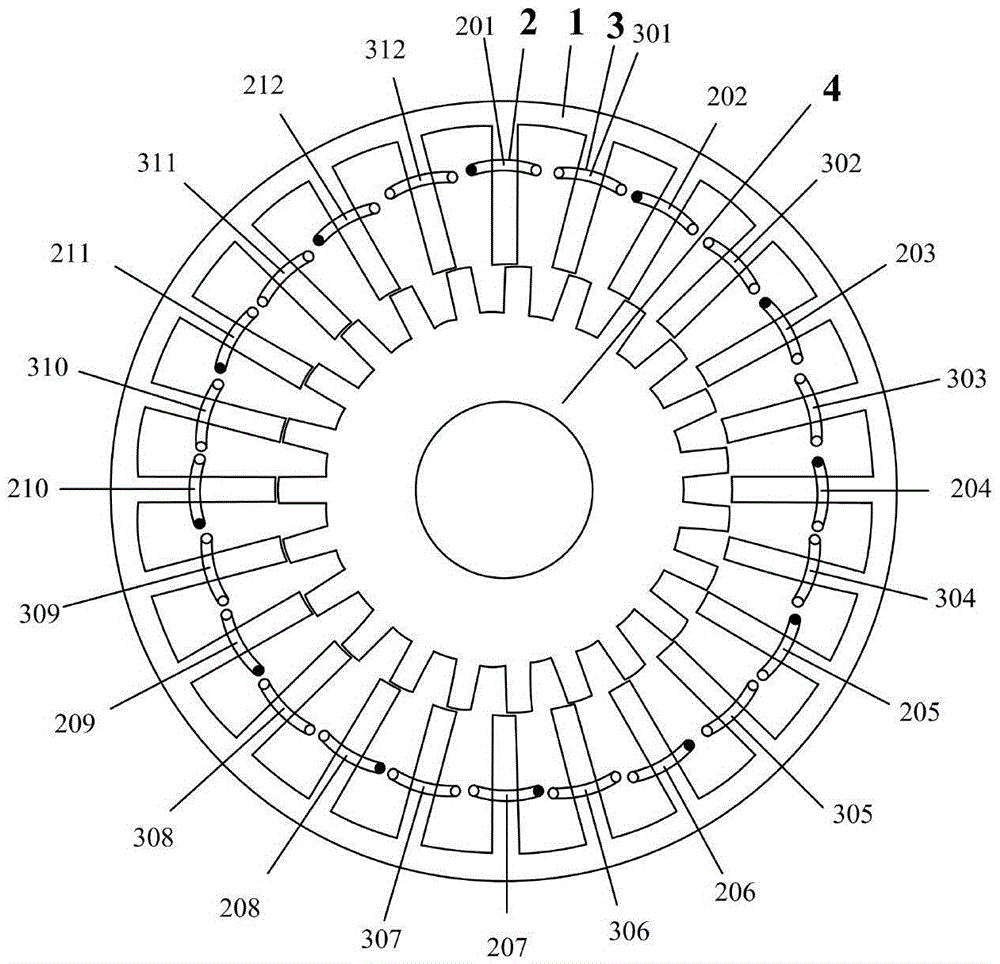

[0015] A six-phase statically sealed high-temperature superconducting motor, such as figure 1 As shown, including the stator 1 and the rotor 4 located in the stator 1, the stator 1 and the rotor 4 are both salient pole structures, and the stator 1 is provided with 24 salient poles, which alternate along the circumferential direction of the stator 1 on the salient poles of the stator 1 Twelve armature windings 3 and 12 field windings 2 are wound; the armature windings 3 are directly wound on the salient poles of the stator 1, and two adjacent armature windings 3 along the circumferential direction of the stator 1 form one phase, The 12 armature windings 3 constitute 6 phases in total. The armature winding 3 is a copper winding wound on the salient pole of the stator 1; the excitation winding 2 is wound by a high temperature superconducting wire. The rotor 4 is provided with 25 or 23 salient poles.

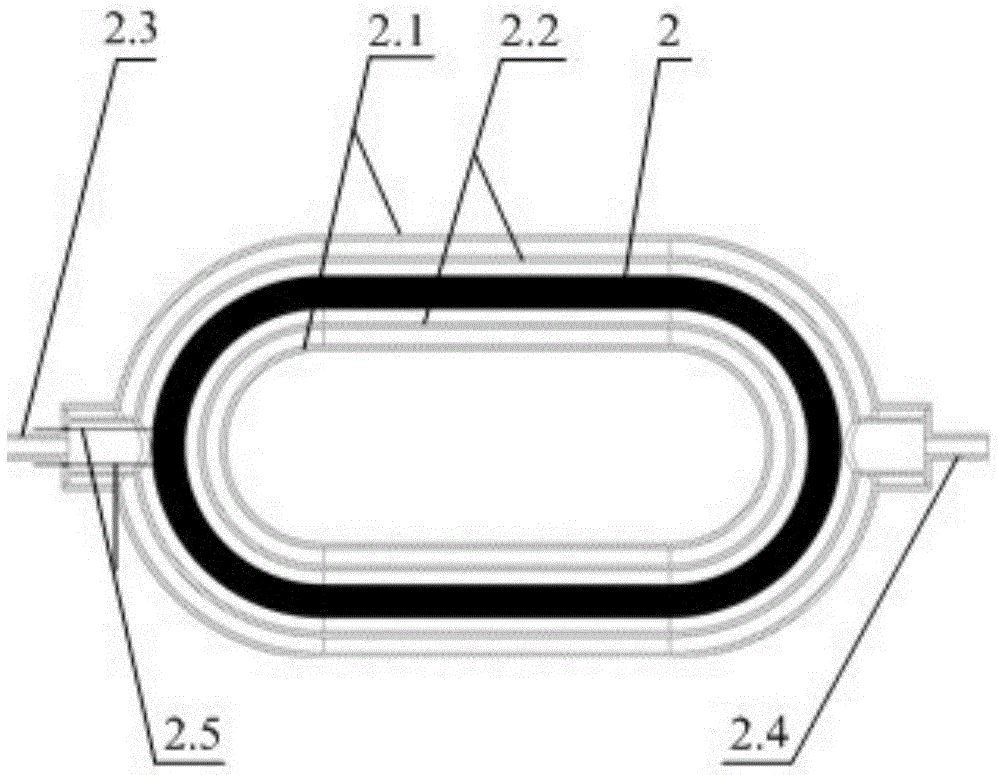

[0016] The excitation windings 2 are placed in a racetrack-shaped cooling Dew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com