Device of measuring thickness of steel strip during production process by using distance sensor

A distance sensor and production process technology, applied in the field of steel strip thickness detection, can solve problems such as error-prone, inconvenient detection, and influence on the accuracy of steel strip thickness detection, so as to prevent the threat of electric shock, avoid inaccurate measurement, and structure simple compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

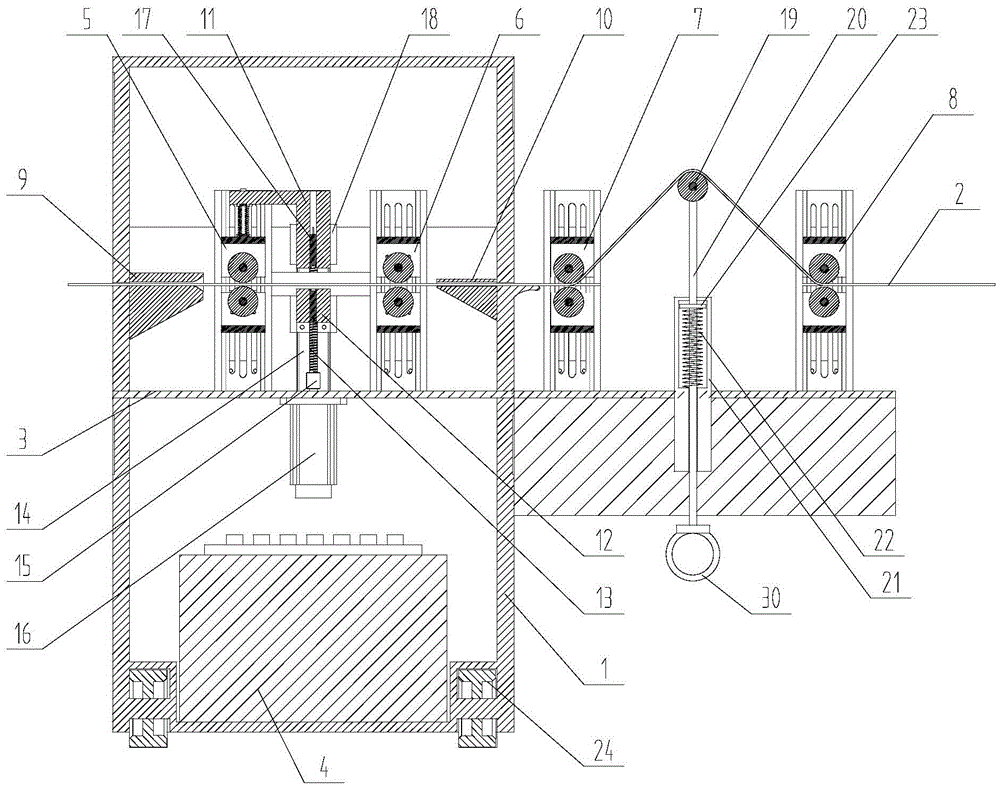

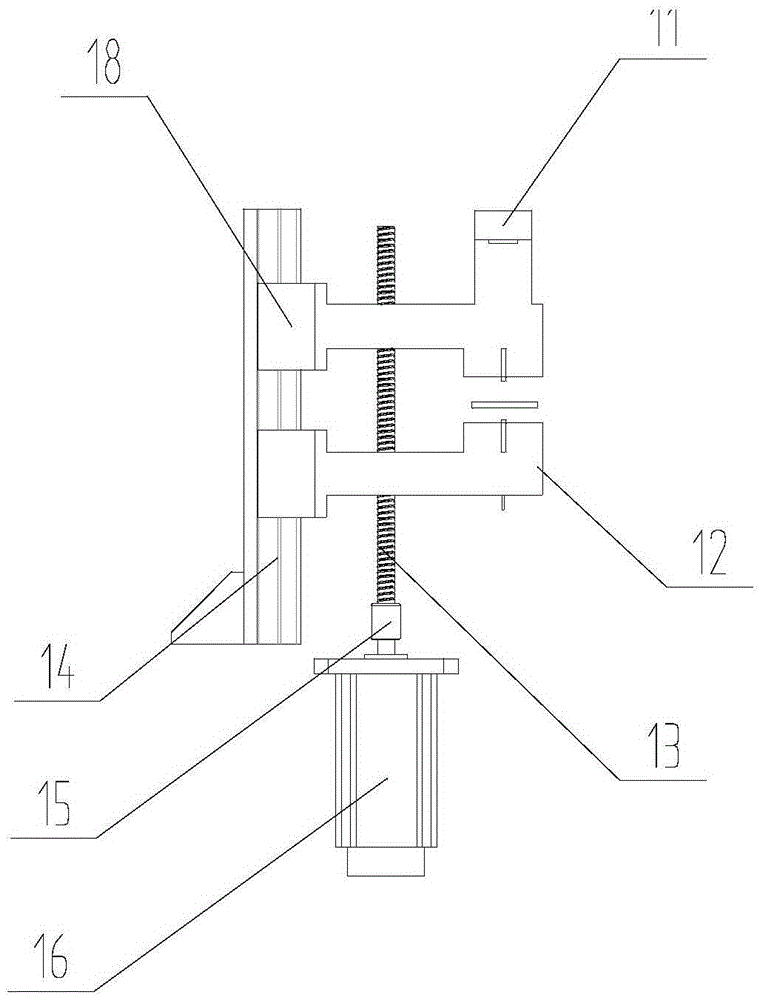

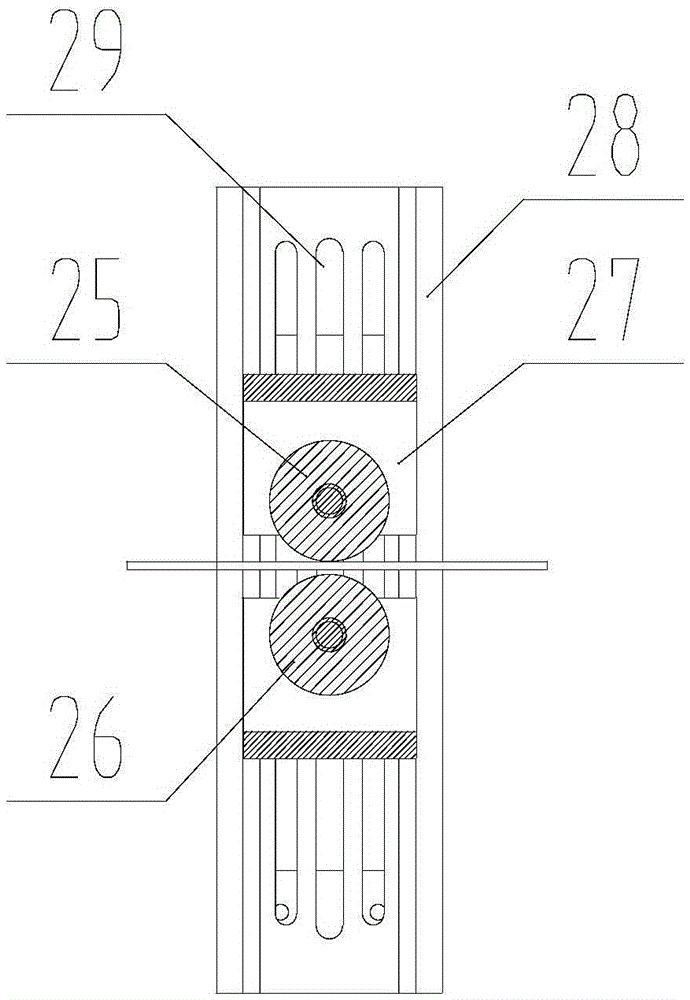

[0029] Below in conjunction with accompanying drawing, the present invention is further described:

[0030] refer to Figure 1-3As shown, a device of the present invention that utilizes a distance sensor to measure the thickness of a steel strip in the production process includes a box-type housing 1, a support plate 3, a rechargeable battery 4, a flattening device, a pair of distance sensors 31, four pairs of drive roller groups, Steel belt buffer device and pressure detection device, the support plate 3 is arranged horizontally, a part of the support plate 3 is fixed inside the box-type casing 1, and the other part protrudes from one side of the box-type casing 1, and the rechargeable battery 4 Fixed on the bottom plate of the box-type shell 1, the four pairs of driving rollers are respectively located in the first driving roller group 5, the second driving roller group 6, the third driving roller group 7 and the fourth driving roller group 8, the first driving roller group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com