Rotor oil pump

A rotor oil pump and oil pump technology, which is applied to lubricating pumps, mechanical equipment, engine components, etc., can solve problems such as large gas content in engine oil, air inhalation at the oil suction port, damage to bearing bushes, and hydraulic tappet components, etc., to reduce engine oil. Effect of air content, reduction of friction loss, and reduction of sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

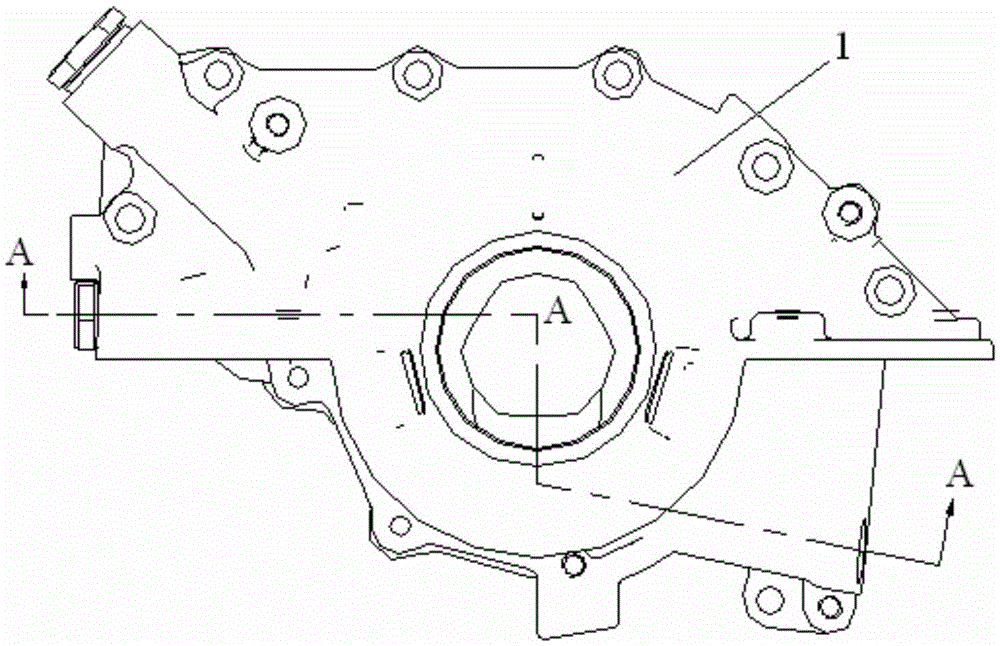

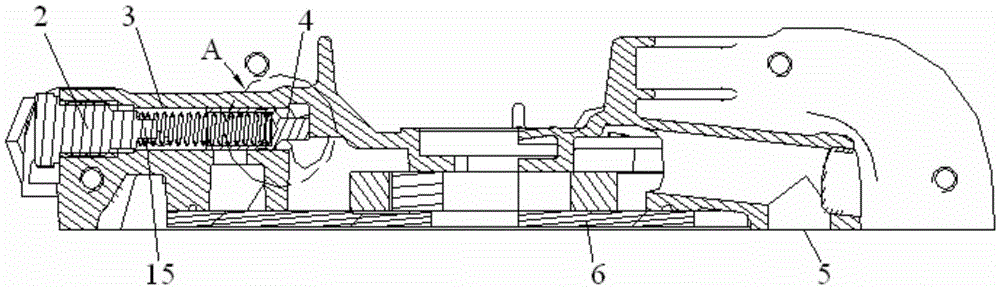

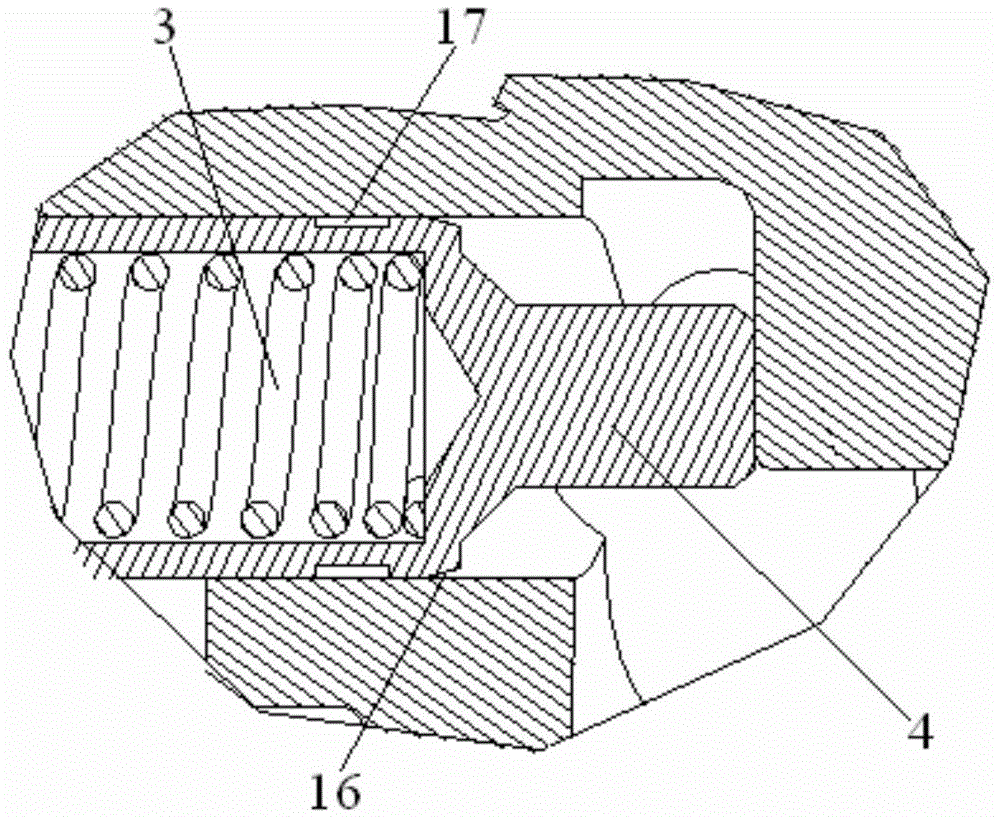

[0032] Such as figure 1 , figure 2 The structure of the present invention expressed is a rotor oil pump, including an oil pump housing 1 , an inner rotor 7 , and an outer rotor 8 . The oil pump housing 1 is provided with an oil inlet 5 and an oil outlet 12 . The inner rotor 7 and the outer rotor 8 are arranged in the cavity formed by the oil pump cover plate 6 and the oil pump housing 1 .

[0033] The rotor oil pump is fastened and installed by cross-recessed bolts 13 .

[0034] In order to solve the problems existing in the prior art and overcome its defects, realize the invention purpose of reducing the friction loss of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com