A Micro/Off-Grid Compressed Air Energy Storage System Based on Free Piston Expansion/Compressor-Linear Motor

A technology of compressed air energy storage and linear motors, applied in piston pumps, machines/engines, mechanical equipment, etc., can solve the problems of compressed air energy storage systems such as poor taste of heat energy, unadjustable compression/expansion ratio, and reduced power generation efficiency. Achieve the effect of high degree of mechatronics, reduce design cost and improve power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings.

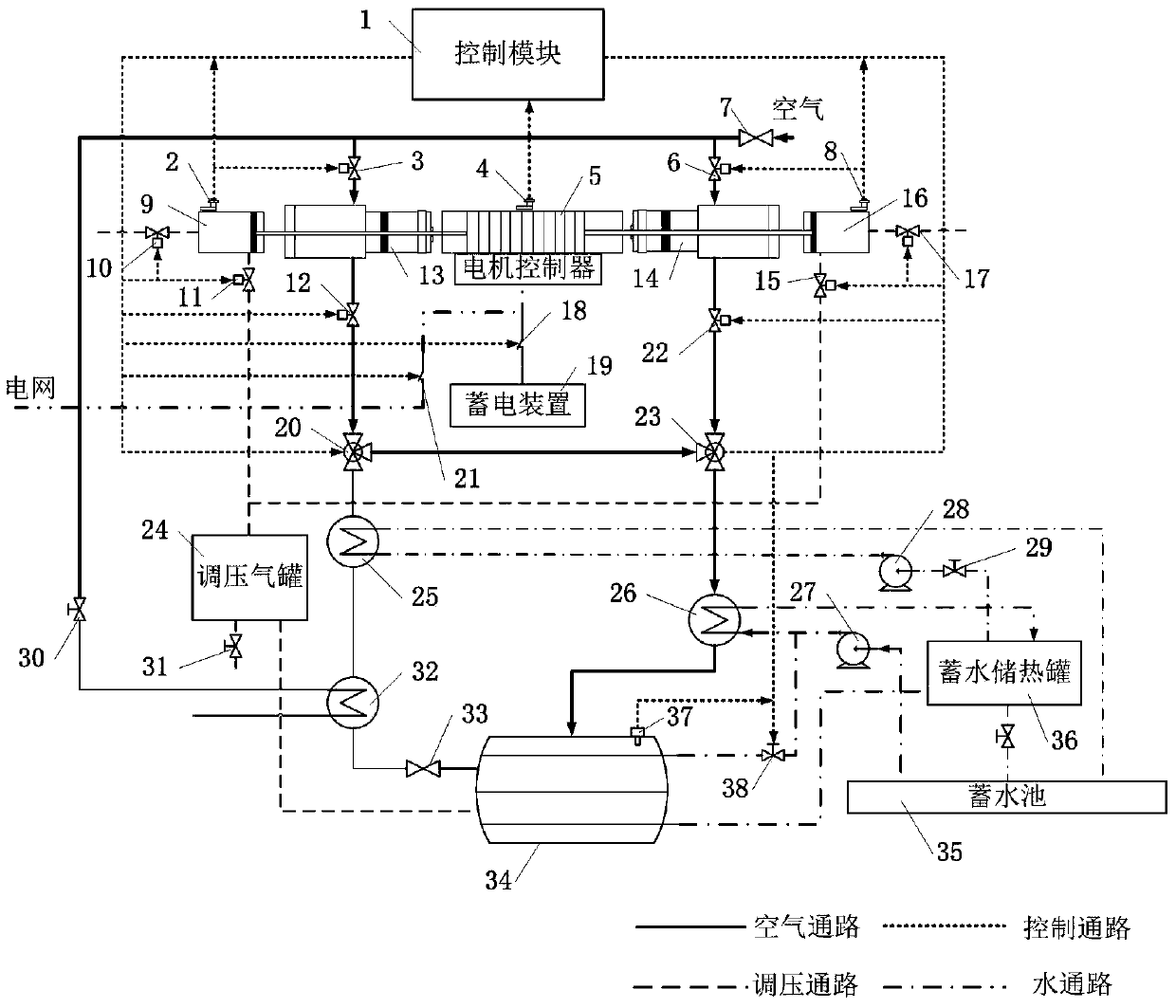

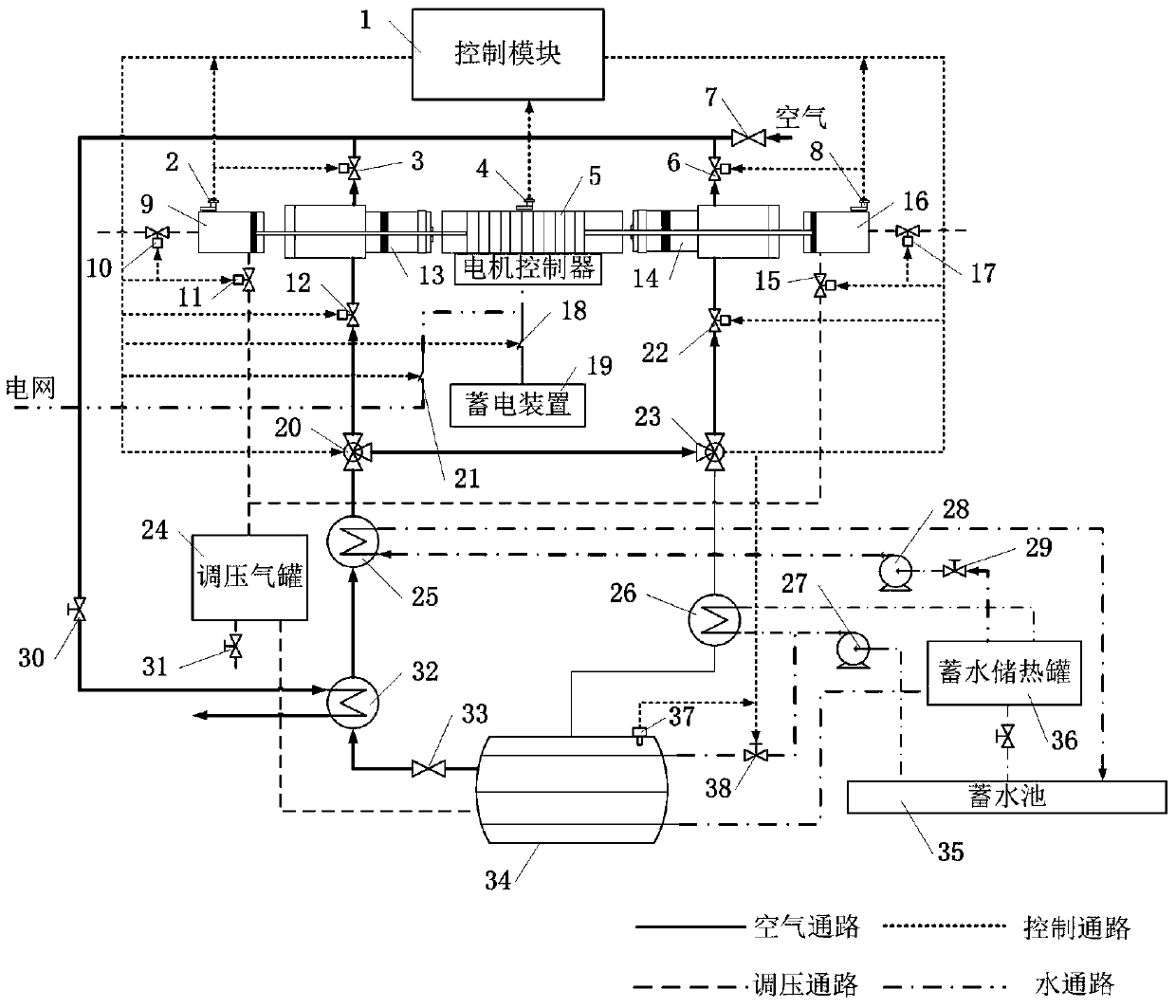

[0020] figure 1 It is a schematic diagram of the energy storage working process of the micro / off-grid compressed air energy storage system, and its connection relationship is as follows: figure 1 As shown, the above micro / off-grid compressed air energy storage system includes a control module (1), pressure sensor one (2), electric valve one (3), displacement sensor (4), linear motor (5), electric valve two (6), pressure sensor two (8), electric valve three (10), electric valve four (11), electric valve five (12), electric valve six (15), electric valve seven (17), electric valve eight ( 22), switch relay one (18), power storage device (19), electromagnetic three-way valve one (20), switch relay two (21), electromagnetic three-way valve two (23), electromagnetic valve one (30), electromagnetic Valve two (38) and corresponding connecting lines;

[0021] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com