Runner rotating in radial direction due to end face stress and pressure power machine of runner

A power machine and the other end face technology, applied in the field of runners and pressure power machines, can solve the problems of low energy, large movement vibration, etc., and achieve the effects of low noise, uniform power transmission and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

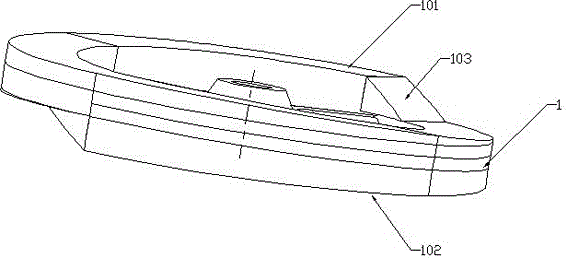

[0019] Such as figure 1 As shown, a runner whose end surface is forced to rotate radially includes a runner body 1, one end surface of the runner body 1 is provided with at least one first helical surface 101, and the other end surface of the runner body 1 is provided with at least one A second helicoid 102, the first helicoid 101 and the second helicoid 102 are arranged at an angle of 180°; the first and second helicoids 101, 102 are respectively provided with a section of transition slope 103 at the junction of the end and the end. The flywheel can also adopt a multi-helicoid structure, that is, when the number of the first helicoids is multiple, the multiple first helicoids are concentrically arranged; when the number of the second helicoids is multiple, the multiple second helicoids are concentrically arranged .

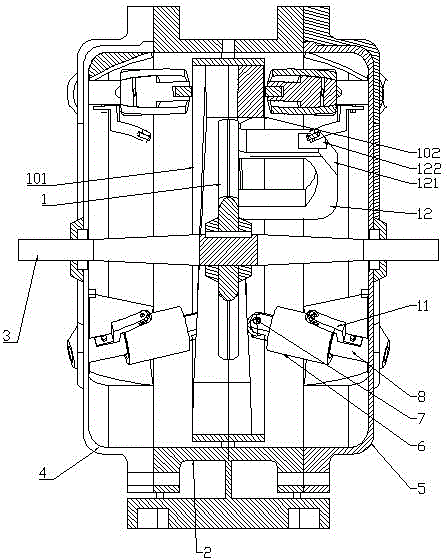

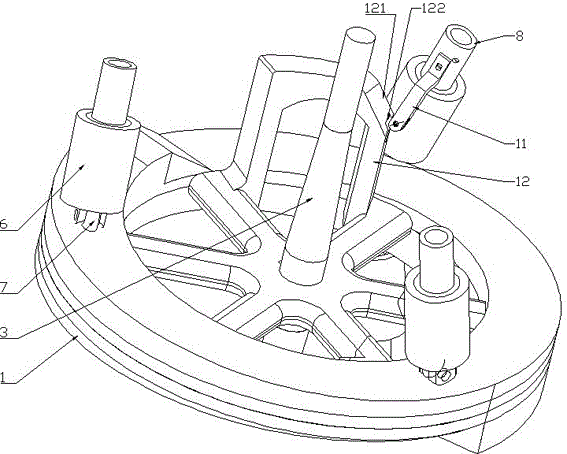

[0020] Such as figure 1 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a pressure power machine using the above-mentioned runner includes a box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com