Water-controlling and oil-stabilizing inflow controller used for oil extraction system

A technology of oil production system and controller, which is applied in the direction of production fluid, earthwork drilling and production, wellbore/well components, etc., and can solve problems such as the throttle hole in the conduction state, easy to be blocked, and the throttle hole is blocked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

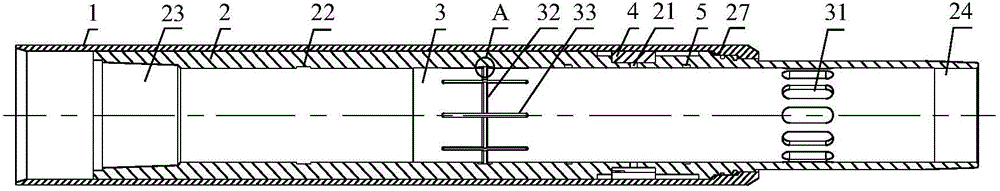

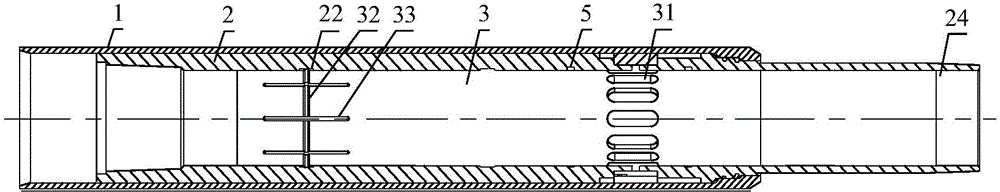

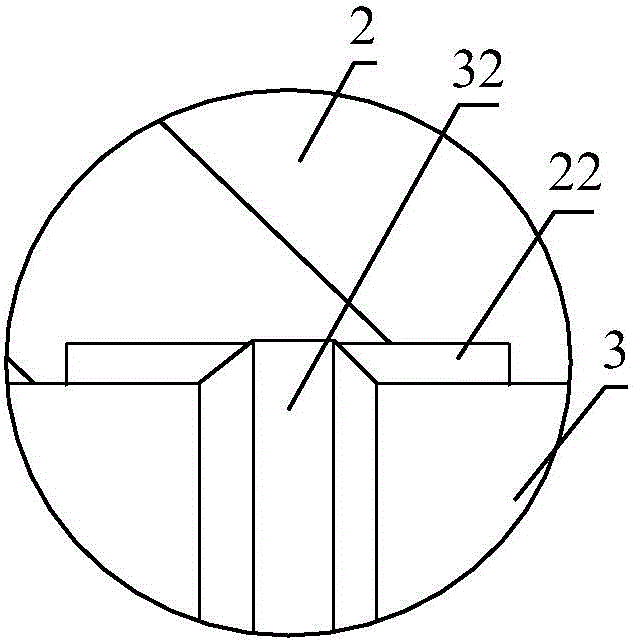

[0035] Such as figure 1 and figure 2 As shown, the controller for controlling water and stabilizing oil flow in the oil production system of the present invention includes a base pipe 2 , a throttling member 4 and a sliding pipe 3 . The base pipe 2 is provided with a throttling nozzle 21 penetrating through its side wall, so that the inside of the base pipe 2 communicates with the outside through the throttling nozzle 21 . A diversion hole 31 is provided on the sliding tube 3 through its side wall, so that the inside of the sliding tube 3 communicates with the outside through the diversion hole 31 . The throttling piece 4 is arranged on the outside of the base pipe 2 , and the throttling piece 4 is provided with a throttling hole 43 . When the throttling member 4 is arranged on the base pipe 2 , the throttling hole 43 is aligned with the throttling nozzle 21 .

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com