Precast slab type vibration damping rail structural system and matched construction method

A prefabricated board and track technology, applied in the directions of track, track laying, track maintenance, etc., can solve the problems of narrow working surface, frequent track diseases, low construction accuracy, etc., and achieve simple construction procedures, good track smoothness, and construction speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

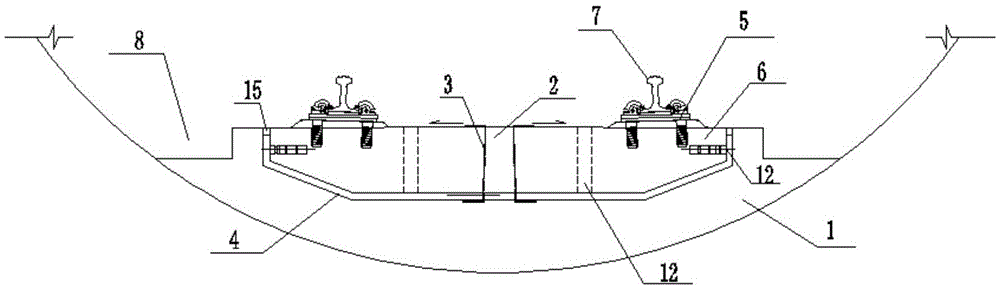

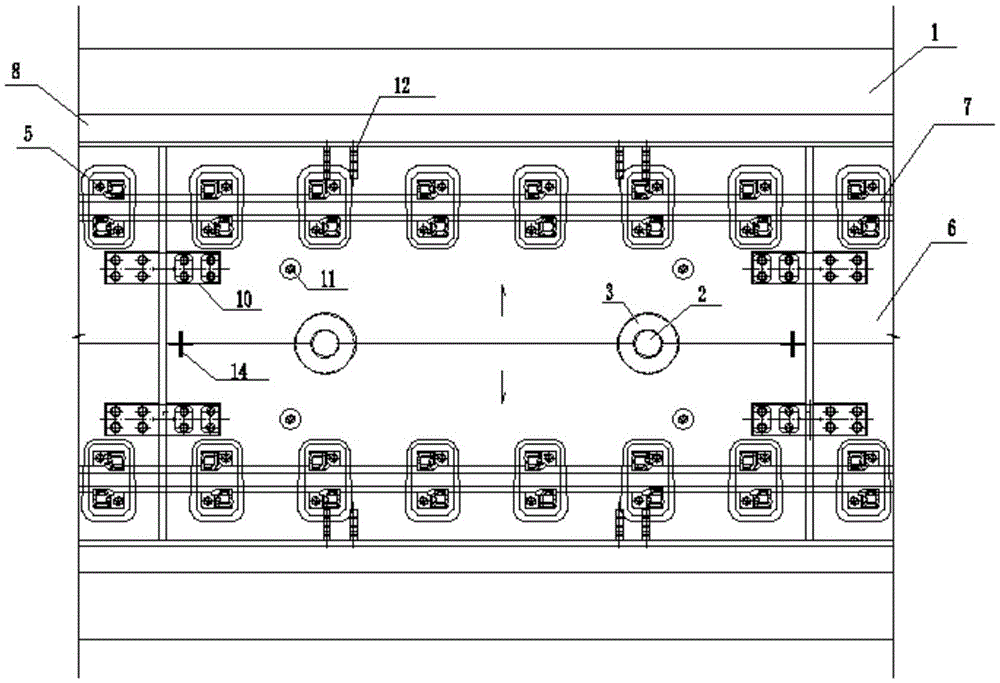

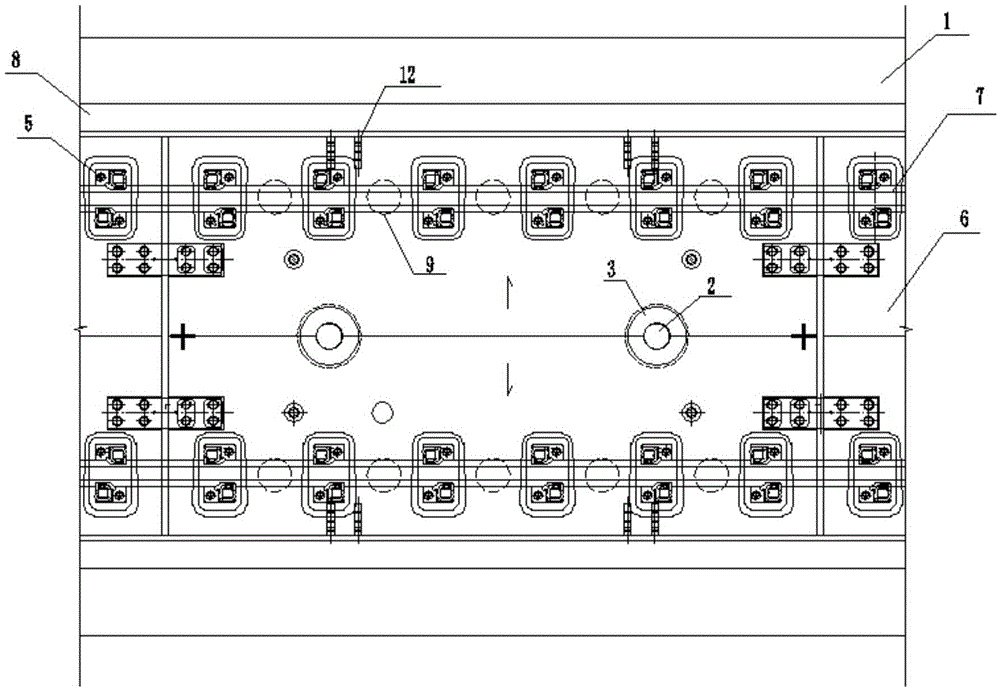

[0050] see figure 1 , The present invention relates to a prefabricated damping track structure system, said prefabricated damping track structure system is multi-layer design, including filling layer 1, elastic cushion layer 4 and track plate 6 sequentially from bottom to top.

[0051] Wherein, the filling layer 1 is the bottom layer, and the elastic cushion layer 4 is laid on the filling layer 1. Preferably, the filling layer is made of self-compacting concrete, so as to provide good fluidity when pouring, and can provide a good support effect. The end of the elastic cushion layer 4 is a sealing material (such as polyurethane caulking glue) 15 to ensure that dust, sundries, water, etc. do not enter the space between the elastic cushion layer 4 and the track 6 or between the elastic cushion layer 4 and the filling layer 1. gap.

[0052] The elastic cushion layer 4 is arranged on the filling layer 1 to provide the elastic cushioning of the filling layer 1 and avoid its rapid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com