A new interlining material coating machine

A new material and coating machine technology, applied in textiles and papermaking, etc., can solve the problems of easy deformation, waste of resources, easy thermal deformation of the interlining roller, etc., and achieve the effect of increasing the overall strength, and the process of changing the tool is simple and easy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

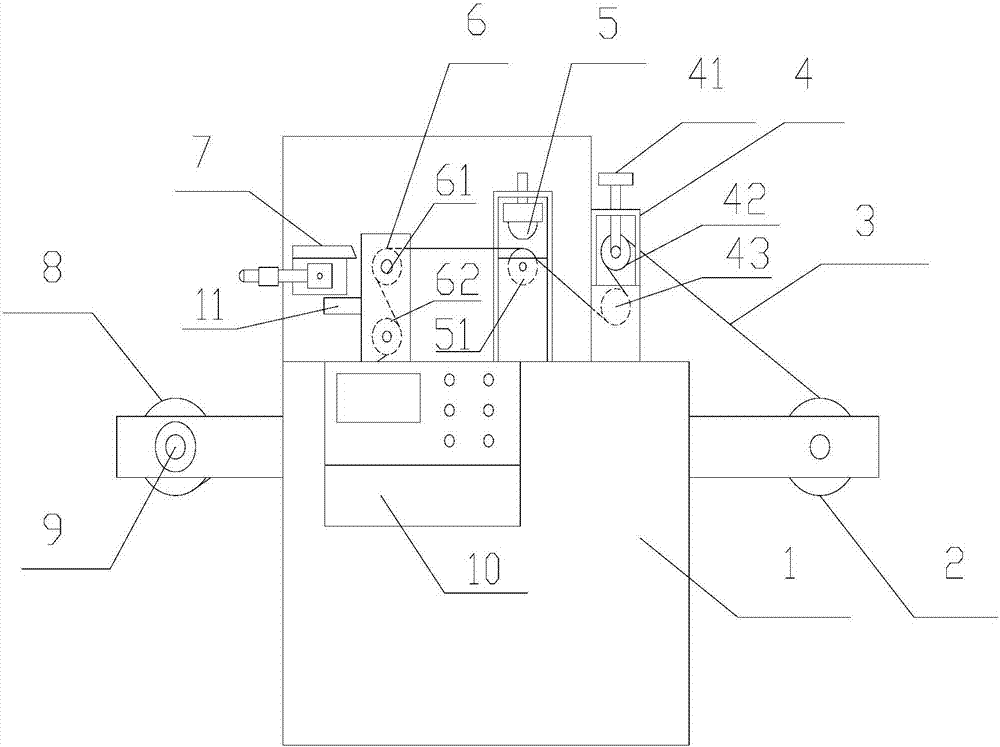

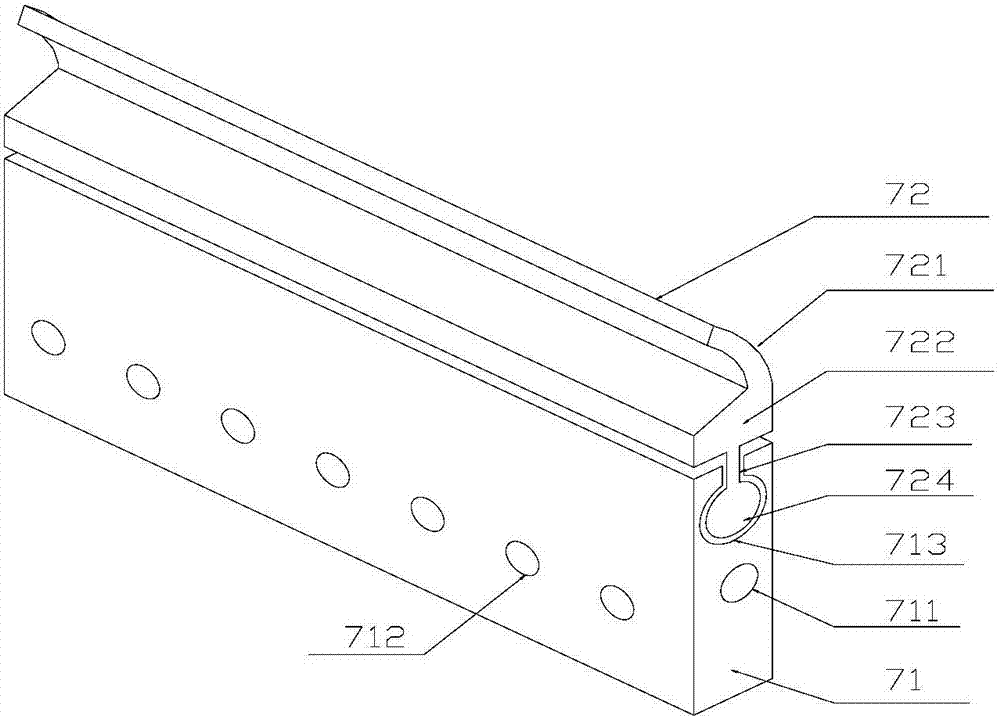

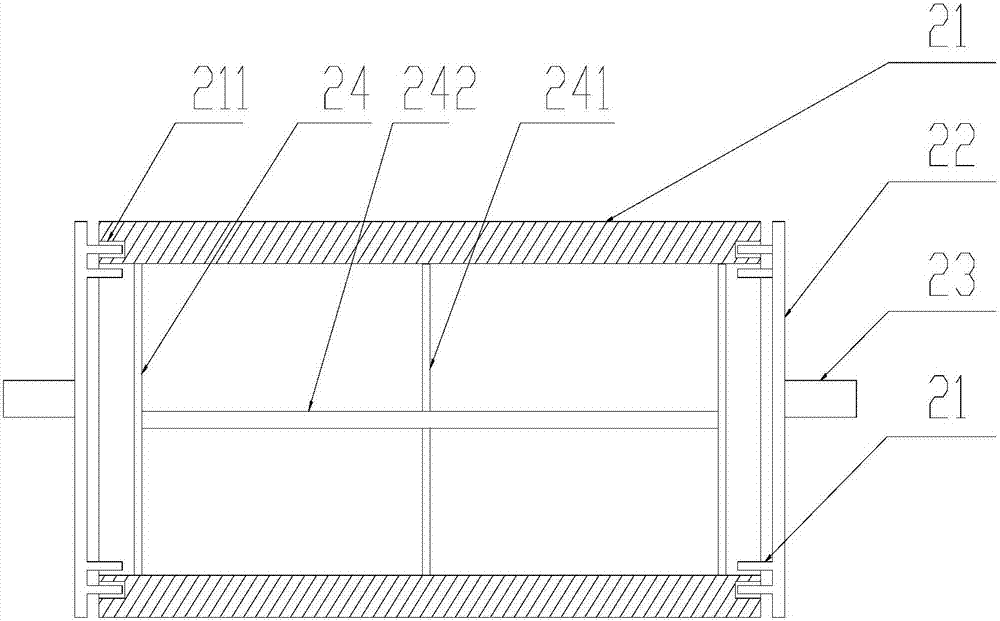

[0016] refer to Figure 1-3 , a coating machine for interlining new materials of the present invention, comprising a body base 1, a cloth introduction roller 2, a cloth 3, a guiding traction mechanism 4, a coating device 5, a guiding mechanism 6, a scraper 7, a winding cylinder 8, and a winding power Motor 9, control device 10 and cooling and drying device 11, the cloth introduction roller 2 is directly installed on the body base 1, the guide traction mechanism 4 includes an elastic adjustment rod 41, an adjustable cloth guide roller 42 and a non-adjustable cloth guide The cylinder 43 and the coating device 5 are directly installed on the body base 1, and the coating auxiliary drum 51 is also installed below the coating device 5, and the guide mechanism 6 is directly fixed on the body base 1, and the guide mechanism 6 Comprising an upper cloth guide roller 61 and a lower cloth guide roller 62, the scraper 7 is directly fixed on the body base 1 through a scraper fixing device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com