A fully automatic and intelligent end-typing machine for filament

A fully automatic, end punching technology, used in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of high labor cost, low work efficiency, low yield rate, etc., and achieve high work efficiency, simple structure, and difficult The effect of bending damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

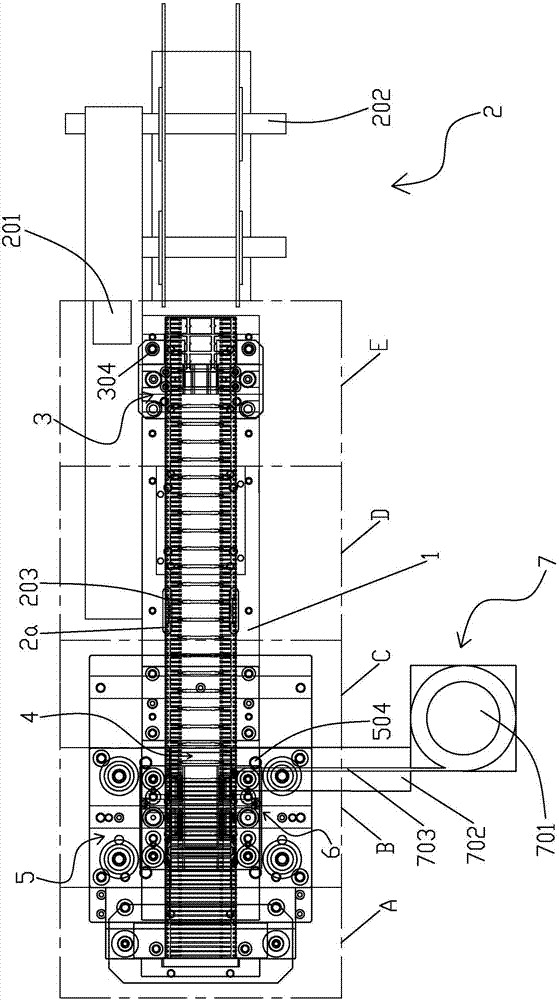

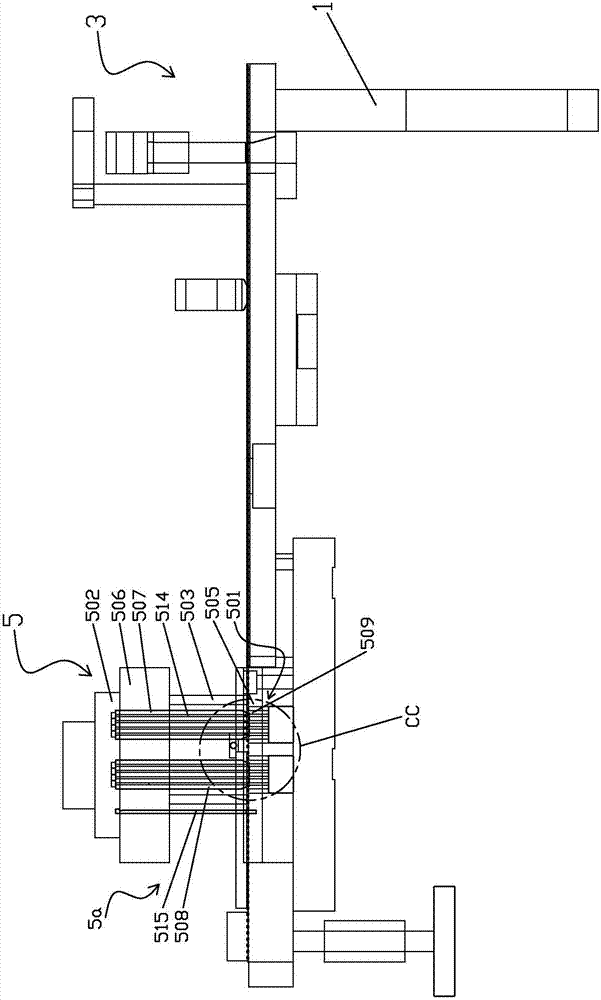

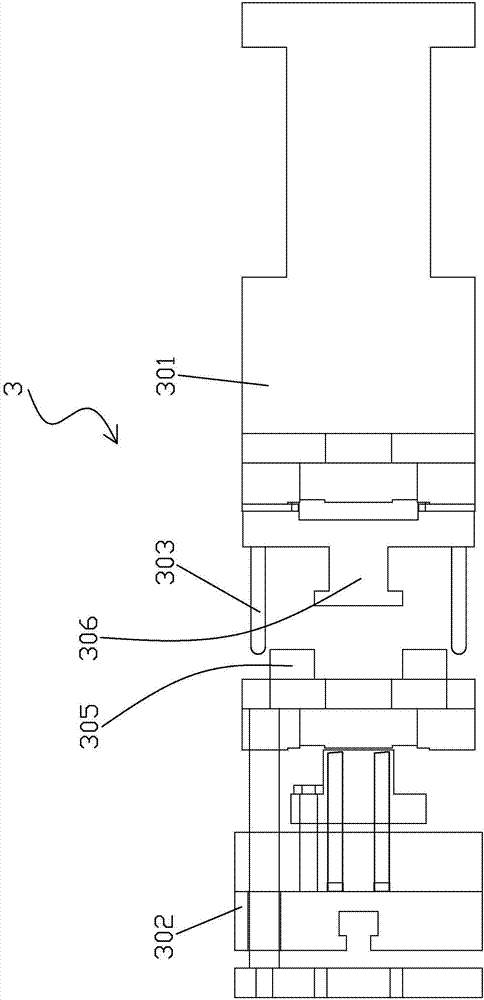

[0031] A fully automatic and intelligent end-typing machine for filaments, comprising a body 1, the body 1 is provided with a conveying device 2 for conveying terminal metal strips, and the conveying device 2 is sequentially provided with connecting terminals along the conveying direction of the terminal metal strips. Rib pre-cutting die 3, solder paste injection device 4 and pressure end mold 5, one side of the pressure end mold 5 is provided with a filament delivery device 7 that can automatically feed the filament into the pressure end groove on the terminal metal strip, The pressure end die 5 includes a lower mold base 501 and an upper mold base 502, the upper mold base 502 is provided with an outer guide column 503, and the lower mold base 501 is provided with the outer guide column for the 503 slides and guides the outer guide hole 504 in it, and the upper side of the lower mold base 501 is provided with a die back plate 505, and the die back plate 505 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com