Packaging machine for packaging by adopting prefabricated bags

A prefabricated bag and packaging machine technology, applied in packaging and other directions, can solve the problems of low packaging efficiency, complicated process, poor packaging effect, etc., and achieve the effect of improving packaging efficiency and solving complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

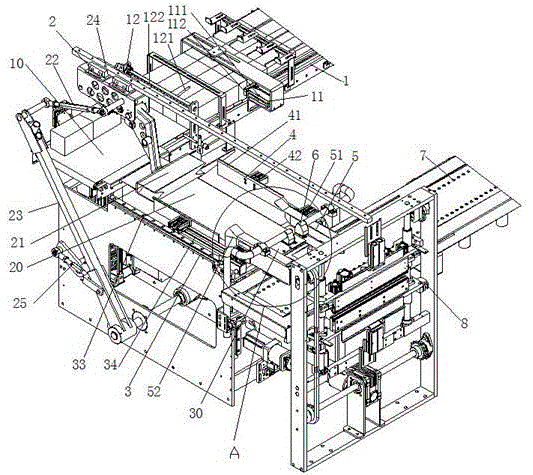

[0078] This embodiment discloses a packaging machine using prefabricated bag packaging, which includes a bag stretching mechanism 5, and also includes a translation mechanism 3 and a conveying device for clamping or holding and conveying. The conveying device is arranged behind the bag stretching mechanism 5. The conveying device is connected with the translation mechanism 3 and is driven by the translation mechanism 3 to reciprocate along the direction of material clamping or holding and conveying.

Embodiment 2

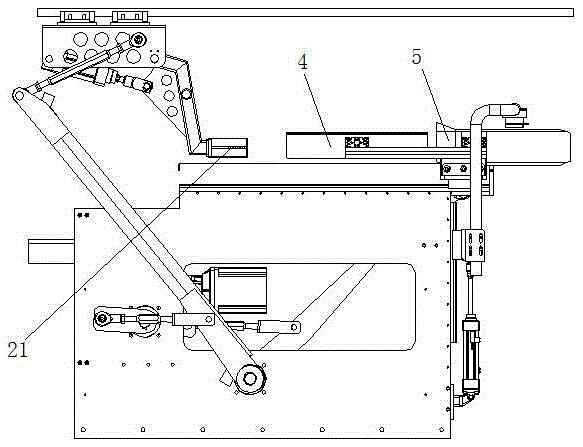

[0080] This embodiment discloses a packaging machine using prefabricated bag packaging, which includes a bag stretching mechanism 5, and also includes a translation mechanism 3 and a conveying device for clamping or holding and conveying. The conveying device is arranged behind the bag stretching mechanism 5. The conveying device is connected to the translation mechanism 3 and is driven by the translation mechanism 3 to reciprocate along the direction of material clamping or holding and conveying;

[0081] Described bag opening mechanism 5 comprises two bag opening plates 52 and two bag opening cylinders 51, two bag opening plates 52 are arranged in parallel, two bag opening plates 52 are respectively connected with a bag opening cylinder 51, two bag opening plates Cylinder 51 drives two bag-opening plates 52 to approach or spread out horizontally. In this embodiment, the structure of the bag stretching mechanism 5 can adopt the structure of the bag stretching mechanism 5 in the...

Embodiment 3

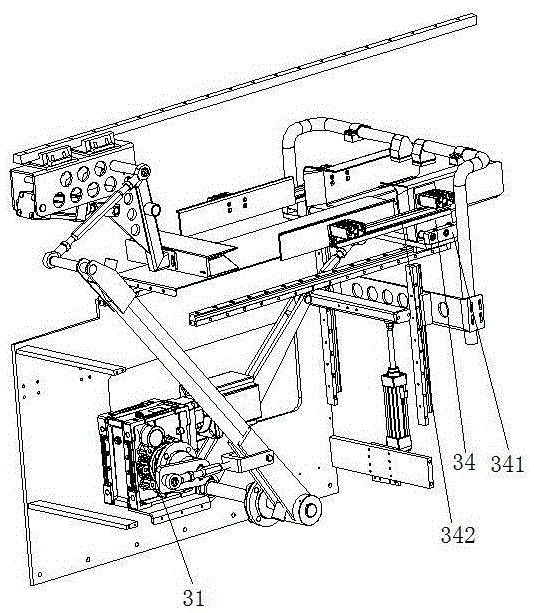

[0083] This embodiment discloses a packaging machine using prefabricated bag packaging, which includes a bag stretching mechanism 5, and also includes a translation mechanism 3 and a conveying device for clamping or holding and conveying. The conveying device is arranged behind the bag stretching mechanism 5. The conveying device is connected to the translation mechanism 3 and is driven by the translation mechanism 3 to reciprocate along the direction of material clamping or holding and conveying;

[0084] Described bag opening mechanism 5 comprises two bag opening plates 52 and two bag opening cylinders 51, two bag opening plates 52 are arranged in parallel, two bag opening plates 52 are respectively connected with a bag opening cylinder 51, two bag opening plates Cylinder 51 drives two bag-opening plates 52 to approach or open horizontally;

[0085] The translation mechanism 3 includes a driver 31, a translation frame 34 connected to the driver 31, and the translation frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com