Lost foam pattern assembly for molten metal pouring lost foam casting

A technology of lost foam casting and metal liquid, which is applied in the field of mold casting, which can solve the problems of easy fracture of the interface, achieve the effect of fast combination speed and reduced gas generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

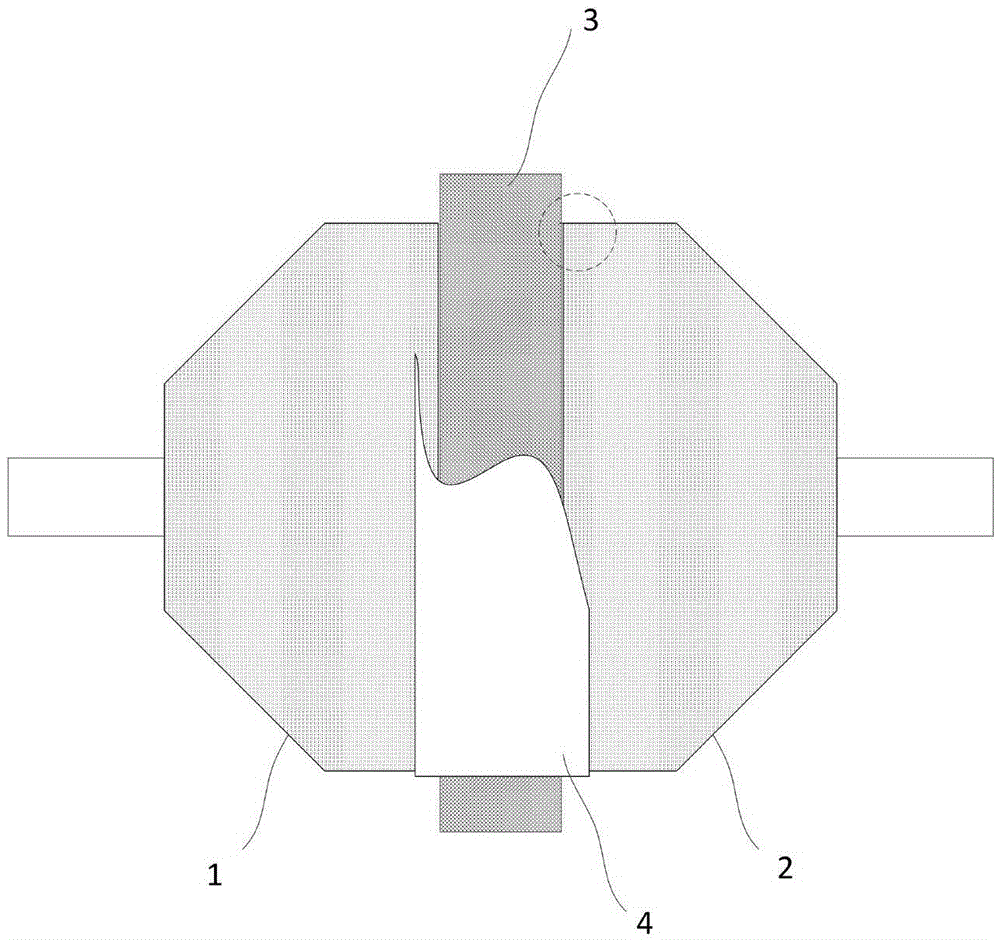

[0029] Please refer to figure 1 , a white mold assembly for metal liquid casting lost foam casting, including a first white module 1, a second white module 2, a filter screen 3 and an adhesive tape 4, and the filter screen 3 is placed in the first white module 1 and the second white module between the joints of the white modules 2, and seal the adhesive tape 4 to the joints of the filter screen 3 and the first white module 1 and the second white module 2.

[0030] Specifically, the filter screen 3 adopts a ceramic foam filter screen 3 .

[0031] Through the above technical solution, the problem of cracking due to the use of adhesives during the bonding of the white molds can be avoided, that is, it is only necessary to use adhesive tape 4 to seal the filter screen 3 and the first white module 1 and the second white module 2 . In addition, since the lost foam is cast under negative pressure, the filter screen 3 can be well connected with the first white module 1 and the second...

Embodiment 2

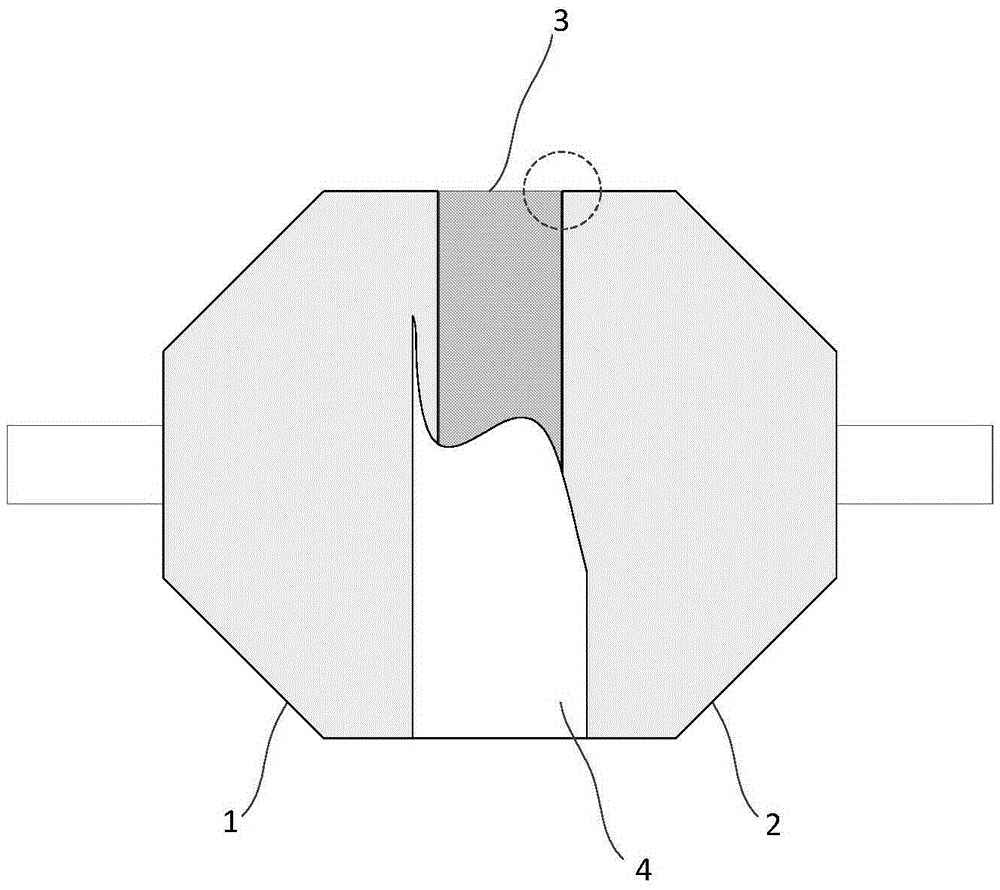

[0033] Further, in order to make the above solution have a better application effect in practice, another kind of white mold assembly for the lost foam casting of the metal liquid casting is also provided, see figure 2 As shown, the white mold assembly for the metal liquid casting lost foam casting includes a first white module 1, a second white module 2, a filter 3 and an adhesive tape 4, and the filter 3 is placed in the first white module 1 and the junction of the second white module 2, and the two ends of the filter screen 3 are flush with the junction of the first white module 1 and the second white module 2, and the adhesive tape 4 is sealed on the The junction of the filter screen 3 and the first white module 1 and the second white module 2 .

[0034] The difference between the white mold assembly for the liquid metal pouring lost foam casting in the second embodiment and the first embodiment is that the filter screen 3 is improved to be the same as the first white mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com