Micropressure steam hotpot

A steam and hot pot technology, applied in the field of kitchen utensils, can solve the problems of slow steam flow, affect heating effect, slow flow rate, etc., and achieve the effects of clean food, energy saving, and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

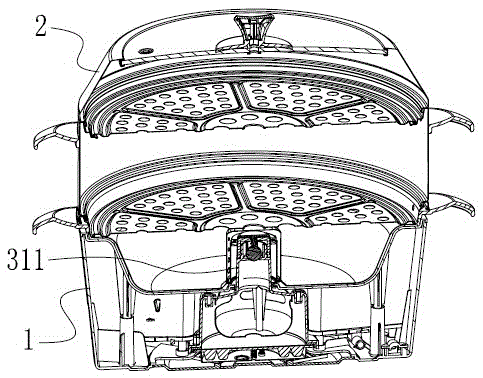

[0041] Such as figure 1 As shown, a micro-pressure steam chafing dish includes a base 1 and a steamer 2 placed on the base 1 .

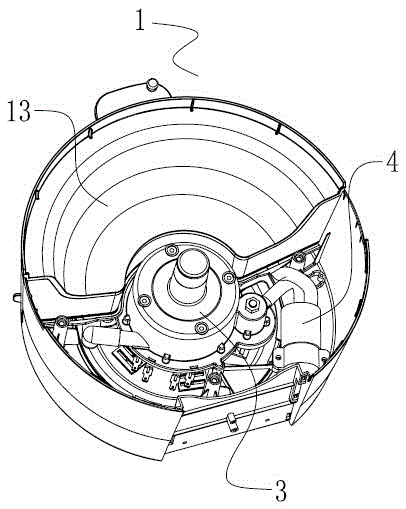

[0042] Such as figure 2 As shown, the base 1 is provided with a steam generator 3 and a water pump 4 .

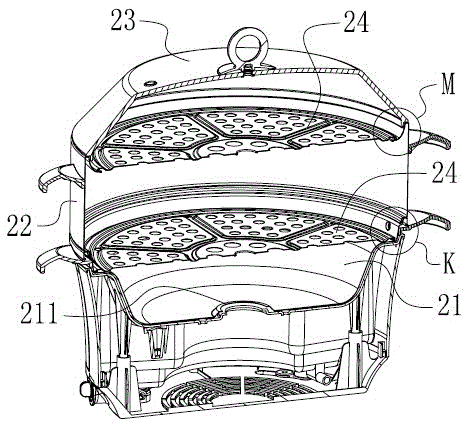

[0043] Such as image 3 As shown, the steamer 2 includes a bottom pot 21 placed on the base 1, a cage tube 22 placed on the bottom pot 21, a pot cover 23 that can be buckled on the bottom pot 21 and the cage tube 22, the bottom pot 21 and the cage tube A steaming tray 24 is placed in the 22.

[0044] Such as Figure 6 As shown, the steam generator 3 includes a shell, which includes an upper shell 31 with a lower opening, and a stainless steel sealing plate 32 that closes the lower opening of the upper shell 31 .

[0045] A vertical steam outlet 311 is provided in the middle of the top of the upper housing 31, and a circular steam outlet 312 is provided at the upper end of the steam outlet 311, and an annular flange coaxial with the steam out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com