Manufacturing method of liquid crystal display device

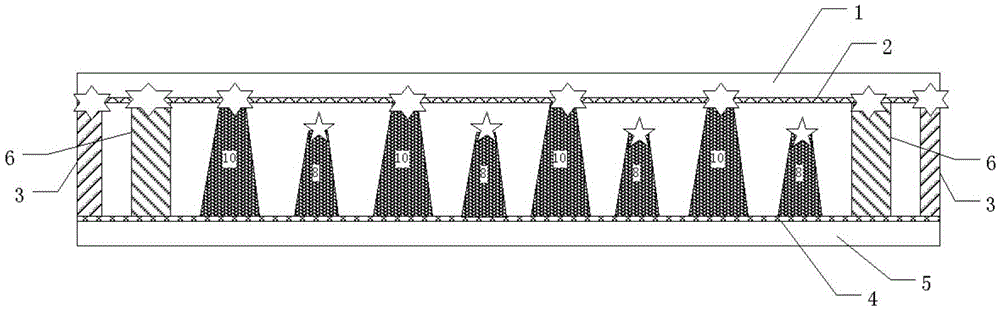

一种液晶显示装置、制作方法的技术,应用在非线性光学、仪器、光学等方向,能够解决液晶面板破裂、损失等问题,达到降低概率、提升抗滑动能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 5 example

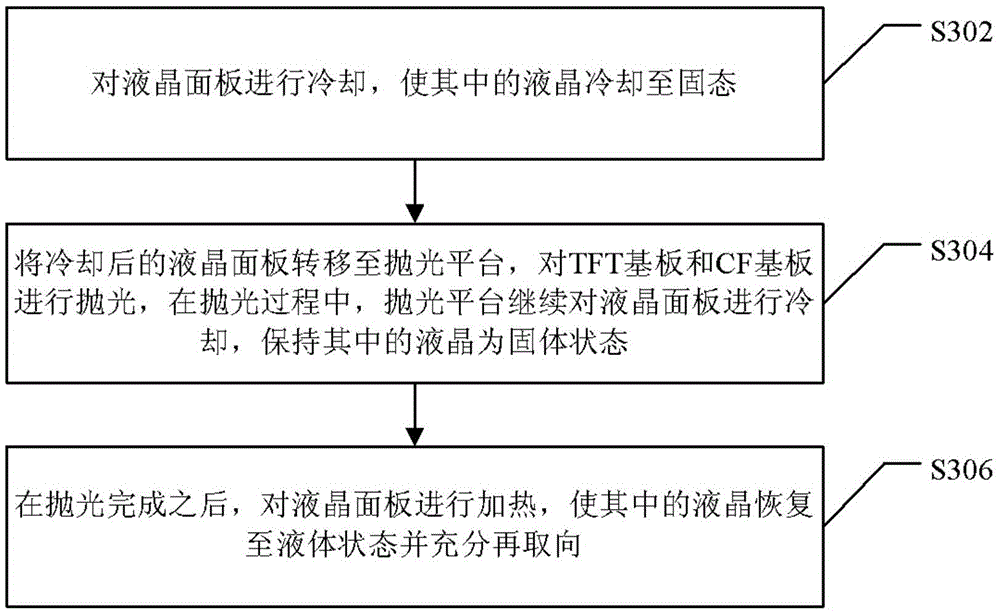

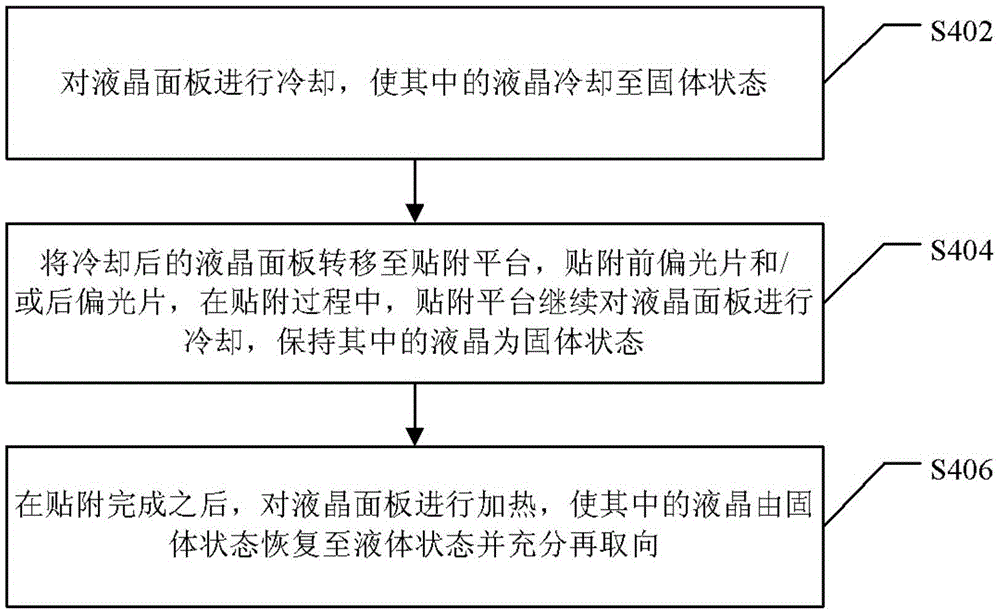

[0078] Based on the above four embodiments, in the fifth exemplary embodiment of the present invention, a method for manufacturing a liquid crystal panel is also provided, please refer to Image 6 , the production method includes:

[0079] Step S702: cooling the liquid crystal panel, so that the liquid crystal therein is cooled to a solid state;

[0080] Step S704: Polish the front substrate and the rear substrate of the liquid crystal panel, and keep the liquid crystal in the substrate in a solid state during the polishing process;

[0081] Step S706: attaching a polarizing plate on the liquid crystal panel, and keeping the liquid crystal in the substrate in a solid state during the attaching process;

[0082] Step S708: Assemble a backlight on the liquid crystal panel, and keep the liquid crystal in the substrate in a solid state during the assembly process;

[0083] Step S710: attaching a touch screen on the liquid crystal panel, and keeping the liquid crystal in the subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com