Vibration station for transverse sensitivity calibration of piezoelectric acceleration sensor

An acceleration sensor, lateral sensitivity technology, applied in the testing/calibration of speed/acceleration/shock measurement equipment, speed/acceleration/shock measurement, instruments, etc., can solve problems such as control difficulties, and achieve compact structure and large working stroke. , the effect of reducing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

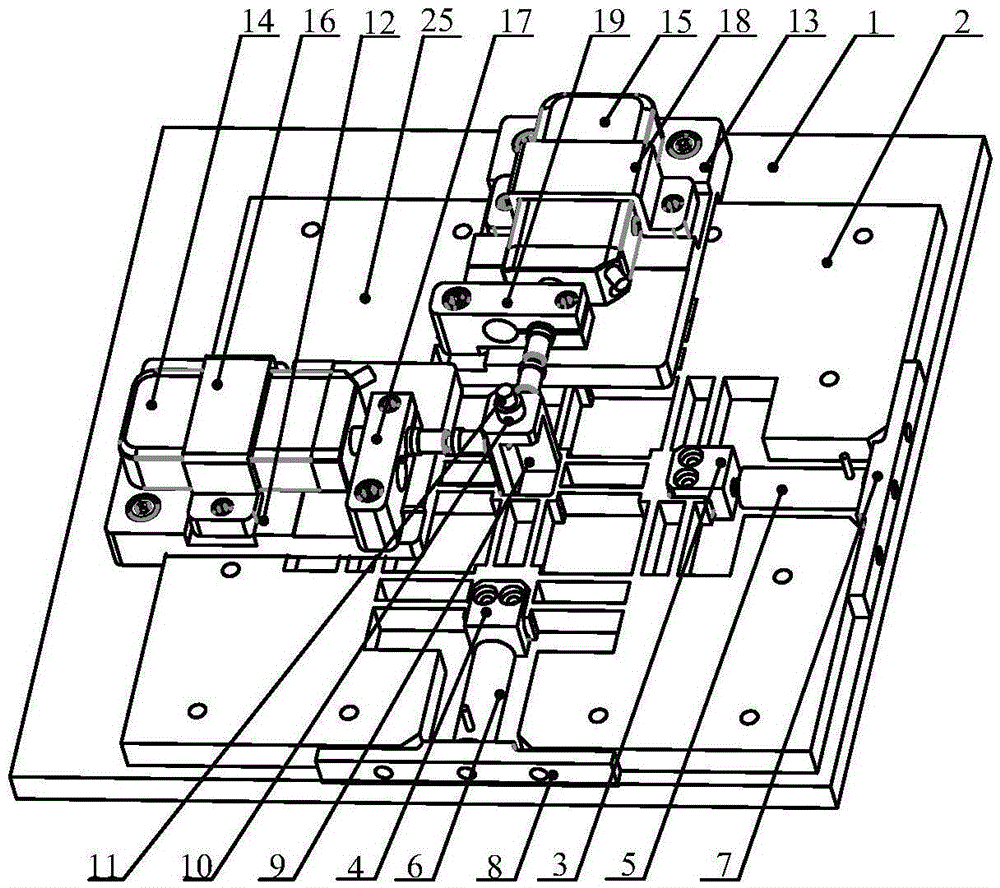

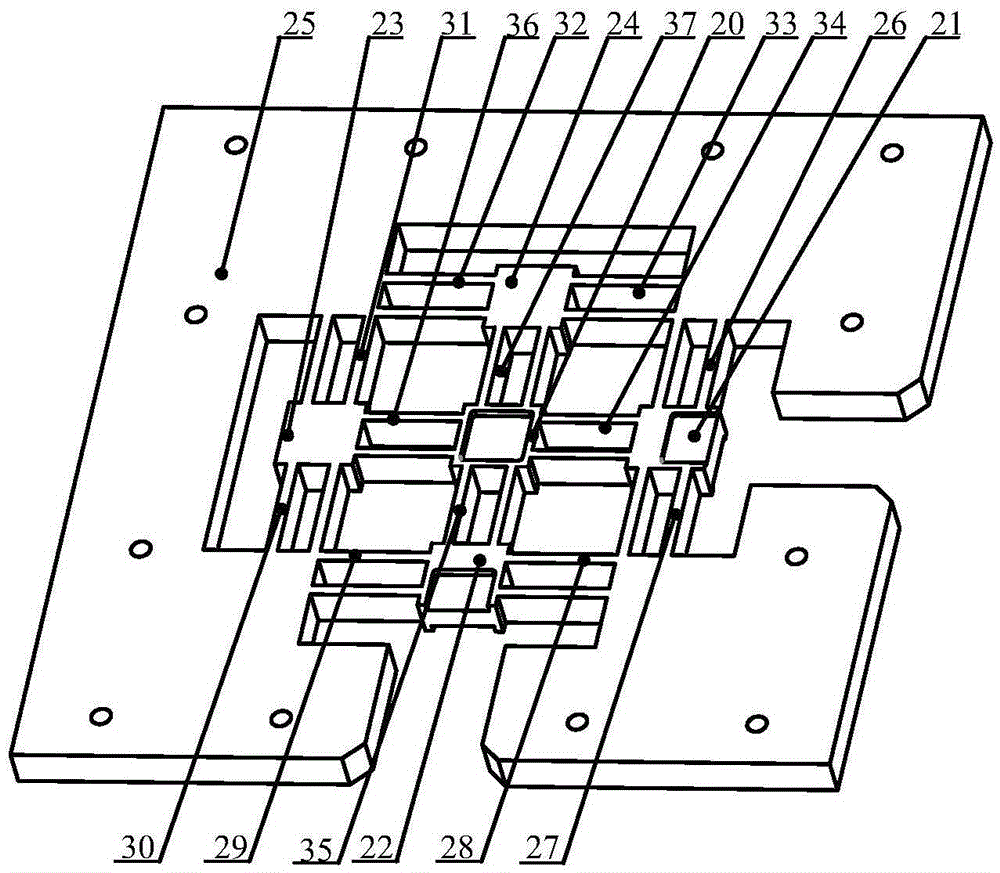

[0017] The present invention proposes a vibrating table for lateral sensitivity calibration of piezoelectric acceleration sensors. The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The vibrating table is composed of a flexible hinge mechanism fixed on a planar two-axis vibration generating device.

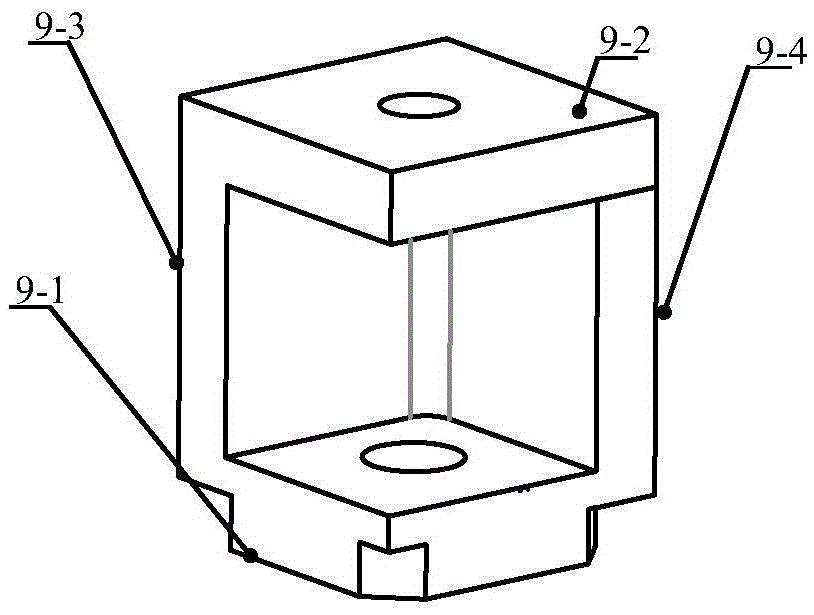

[0018] Such as figure 1 Shown is a schematic diagram of the vibration table structure for lateral sensitivity calibration: the flexible hinge mechanism 2 is fixed on the air-floating vibration isolation table 1 of the planar two-axis vibration generating device; the first input platform is respectively fixed on the right end and the lower end corresponding to the flexible hinge mechanism 2 The coupling block 3 and the second input platform coupling block 4; the first input platform coupling block 3 is connected with the first piezoelectric ceramic driver 5 through the threads on it, and the second input pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com