Magnetic suspension dynamic vibration absorber as well as vibration absorption system and working method of magnetic suspension dynamic vibration absorber

A technology of dynamic vibration absorber and magnetic levitation, which is applied in the direction of magnetic spring, spring/shock absorber, spring, etc., to achieve the effect of convenient use, improved vibration absorption effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

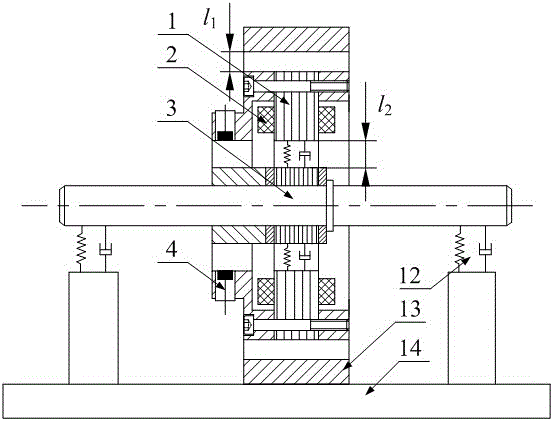

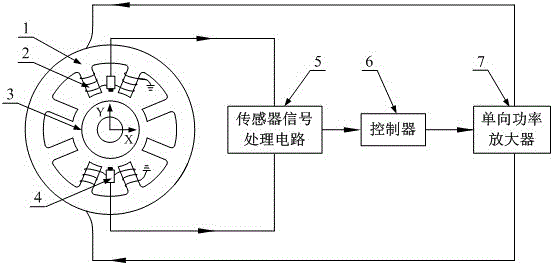

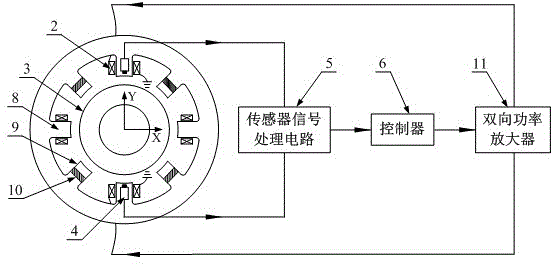

[0024] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The invention discloses a magnetic levitation dynamic vibration absorber, which includes an absorbed element and a vibration absorbing element, and can be divided into active magnetic levitation dynamic vibration absorbers such as figure 2 , hybrid magnetic levitation dynamic vibration absorber such as image 3 The absorbed element of the active electromagnetic dynamic vibration absorber is the rotating shaft 3, and the y-direction vibration-absorbing element of the active magnetic levitation dynamic vibration absorber includes a π-shaped magnetic pole 1, a control winding 2, a displacement sensor 4, and the vibration-absorbing system also includes a sensor signal processing circuit 5, Controller 6 and unidirectional power amplifier 7. The control winding 2 and the π-shaped magnetic pole 1 form an electromagnet, the control winding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com