Construction technology for large-diameter pipeline crossing construction catwalk

A construction technology and catwalk technology, which is applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of long catwalk high-altitude operations, inconvenient transportation of materials and personnel, and long construction period, so as to reduce the risk of high-altitude operations , Improve the effect of catwalk prefabrication and installation level and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

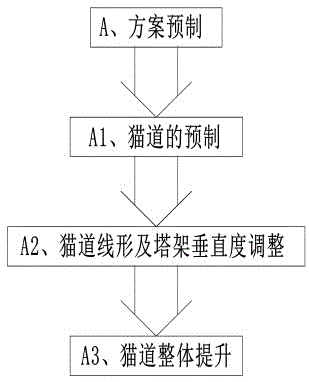

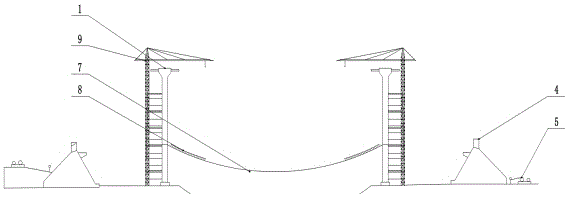

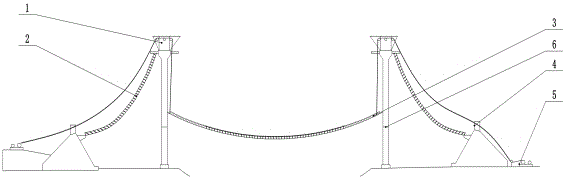

[0029] like figure 1 As shown, the construction process of the large-scale pipeline crossing the construction catwalk includes the following steps: A. Scheme prefabrication: According to the landform characteristics that require the pipeline spanning construction, the force analysis of the tower 1 and the catwalk is carried out, and the offset value of the tower 1 is obtained and catwalk force parameters to determine the process steps; A1, catwalk prefabrication: catwalks include mutually independent mid-span catwalk 3 and side-span catwalk 2, prefabricated mid-span catwalk 3 and side-span catwalk 2, in During the pouring construction stage of the tower 1, fix the mid-span catwalk 3 between the two towers 1; A2, the alignment of the catwalk and the verticality adjustment of the tower 1: install the side-span catwalk 2 on the tower 1, and Adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com