Prevention and reinforcement method of fatigue cracks caused by external deformation of railway steel bridge deck

A fatigue crack, steel bridge deck technology, applied in the direction of bridge reinforcement, bridges, bridge parts, etc., can solve the problem of loss of bearing capacity of main girder, the frequency of occurrence of insufficient research, to prolong life, reduce the degree of stress concentration in welds, The effect of increasing local stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

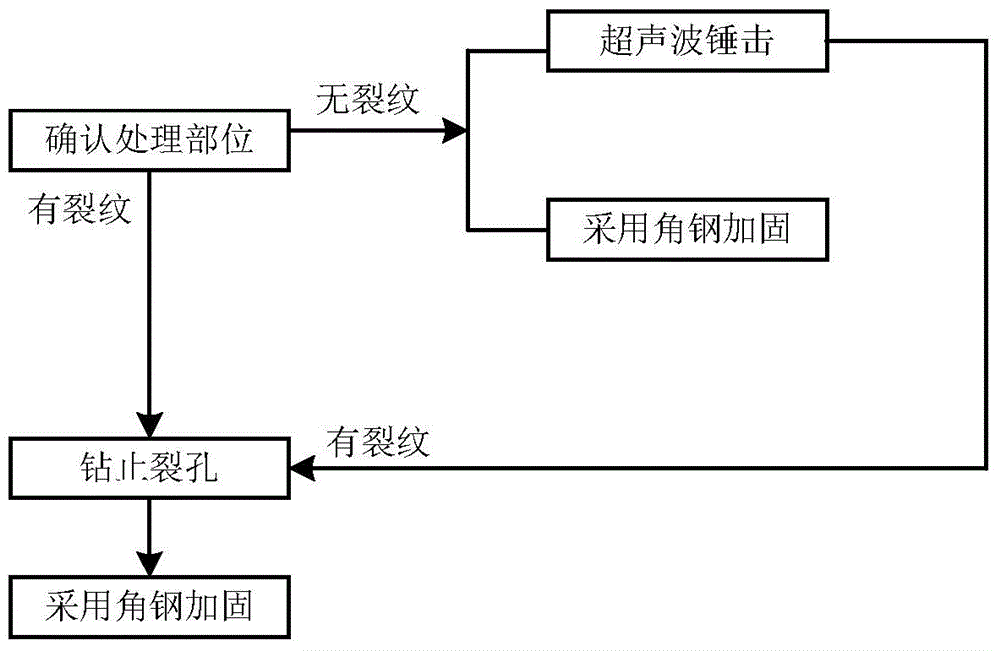

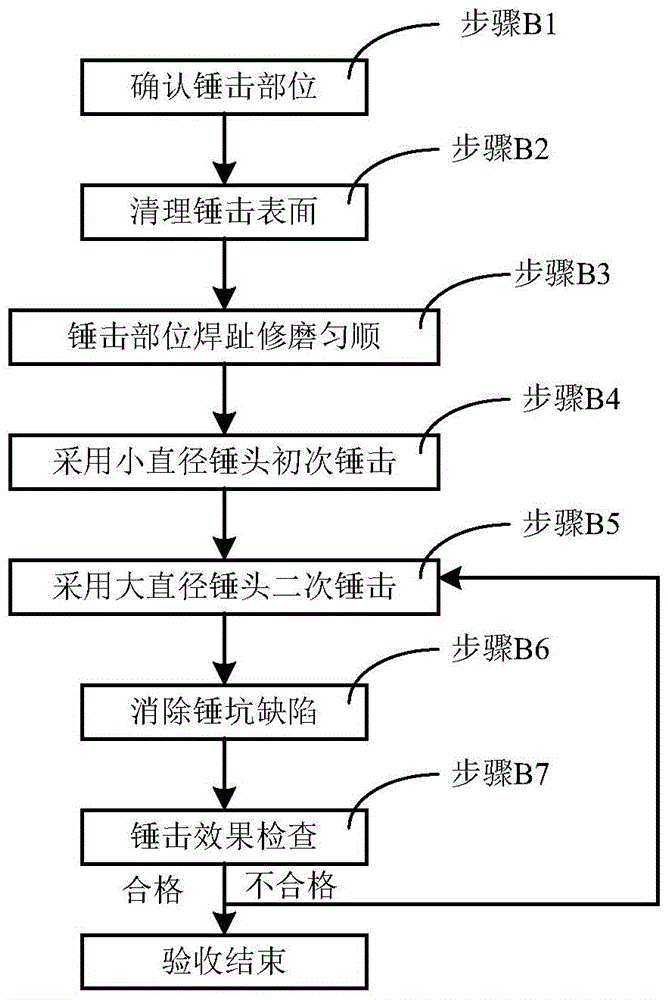

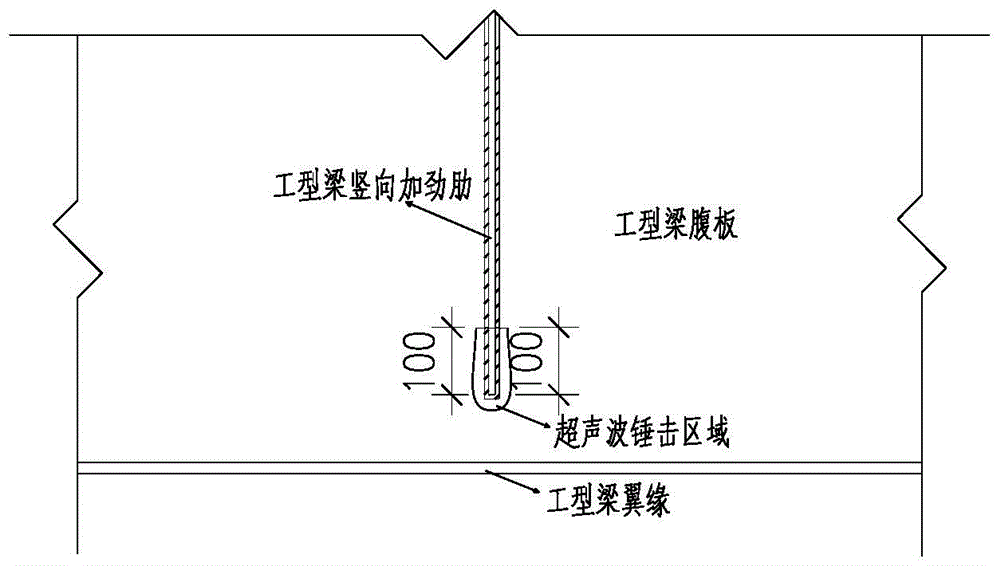

[0036] Example 1, such as figure 1 As shown, a method for preventing and strengthening fatigue cracks caused by external deformation of a railway steel bridge in an embodiment of the present invention, taking the longitudinal girder of a 64m under-supported steel truss girder as an example. The longitudinal beam is made of Q345qD steel with a span of 8m and a height of 1290mm; the upper and lower flanges are 240mm wide and 16mm thick; the web is 1258mm high and 10mm thick; there are five vertical stiffeners on both sides of the web. The prevention and reinforcement method includes a determination step, a hammering step, an arresting step and a reinforcement step.

[0037] The determination step is: by carrying out the actual bridge inspection to the railway steel bridge, determine whether there is a crack in the railway steel bridge, if there is a crack, then carry out the reinforcement step after the crack arrest step, and carry out the crack arrest and reinforcement treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com