Preparation method of organic gel composite phase change material

A composite phase change material and organogel technology, applied in the field of preparation of organogel composite phase change materials, can solve the problems of low loading of composite phase change materials, limited practical application, narrow pore size distribution, etc., to avoid leakage, Wide application range and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

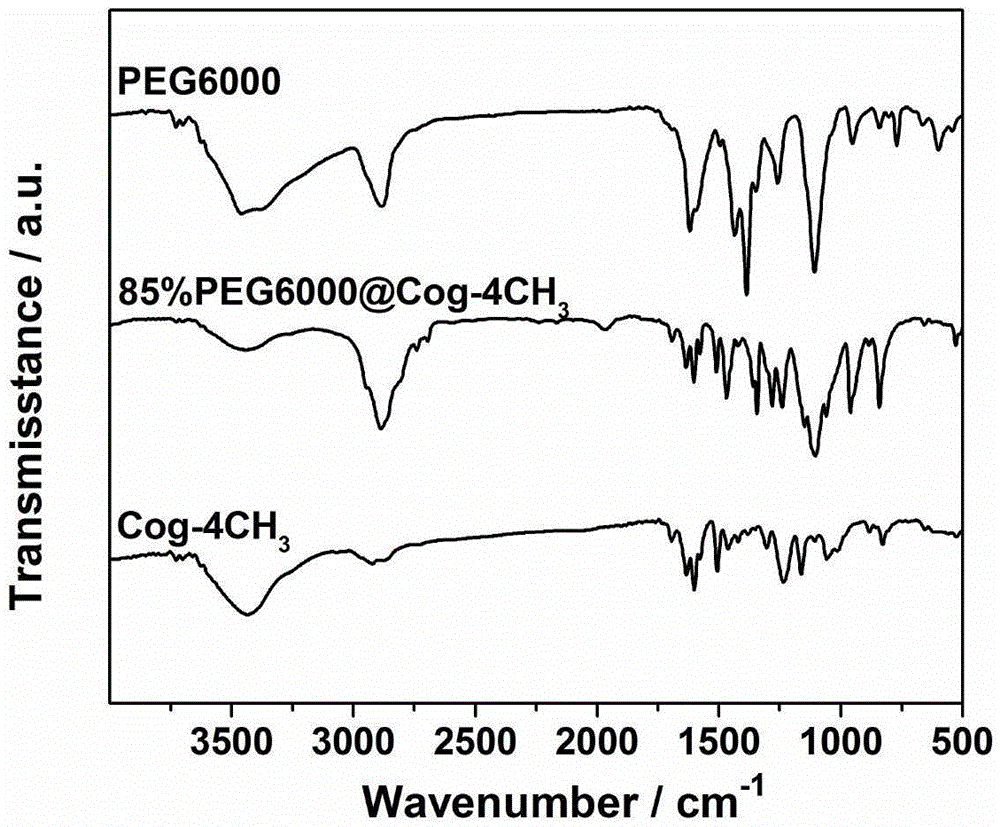

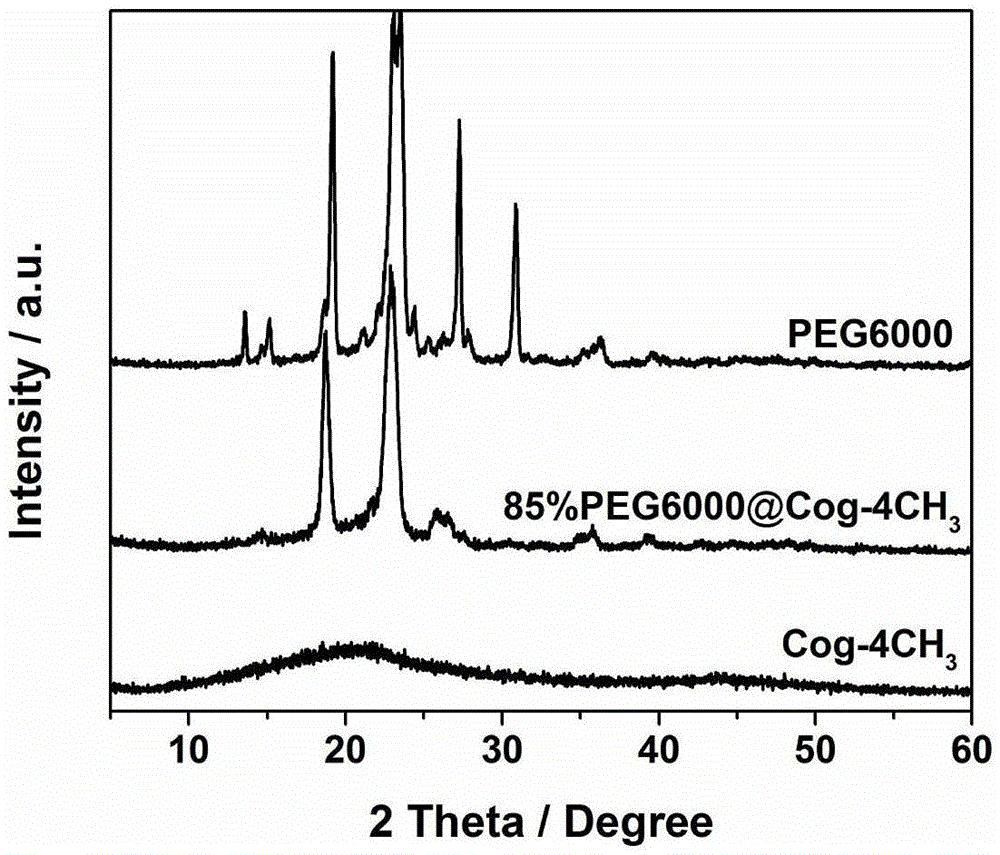

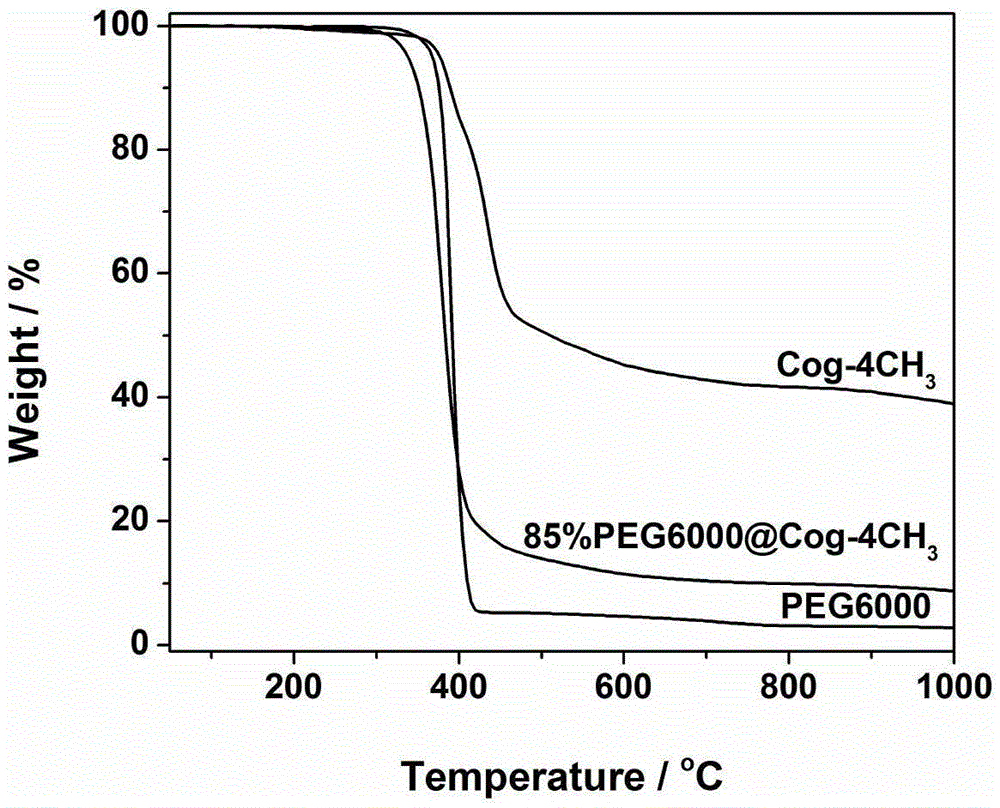

[0029] (1) Add 0.11g of tetramural aldehyde and 0.0657g of 2,3,5,6-tetramethyl-1,4-phenylenediamine into 5mL of 1,4-dioxane and ultrasonically disperse until transparent, then add 0.4mL of 3M acetic acid solution, shake well, put it in an oven at 100°C, let it stand for 24h, and wash the product repeatedly with absolute ethanol to obtain Cog-4CH 3 gel.

[0030] (2) A certain amount of phase change core material PEG6000 (PEG6000 accounts for PEG6000 and Cog-4CH 3 The percentages of the total mass of the gel are respectively 50%, 60%, 70%, 80%, and 85%) dissolved in 10mL of ethanol, uniformly dispersed and then added to the container of the gel material, left to stand at 60°C for 8h, and finally The covalent organogel-based composite phase change material is obtained after solvent removal.

Embodiment example 2

[0032] (1) Add 0.11g of tetrawall aldehyde and 0.0545g of 2,5,-dimethyl-p-phenylenediamine into 5mL of 1,4-dioxane and ultrasonically disperse until transparent, then add 0.4mL of 3M acetic acid solution and shake well Then put it in an oven at 100°C, let it stand for 24h, and wash the product repeatedly with absolute ethanol to obtain Cog-CH 3 gel.

[0033] (2) A certain amount of phase change core material PEG4000 (PEG4000 accounts for PEG4000 and Cog-CH 3 The percentages of the total mass of the gel are respectively 50%, 60%, 70%, 80%, and 85%) dissolved in 10mL of ethanol, uniformly dispersed and then added to the container of the gel material, left to stand at 60°C for 8h, and finally The covalent organogel-based composite phase change material is obtained after solvent removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com