Catenary workpiece handling table

A workbench and catenary technology, applied to conveyor objects, transportation and packaging, conveyor control devices, etc., can solve the problems of positioning accuracy differences, high precision, high cost, etc., to achieve reduced manufacturing costs and fast response speed , easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

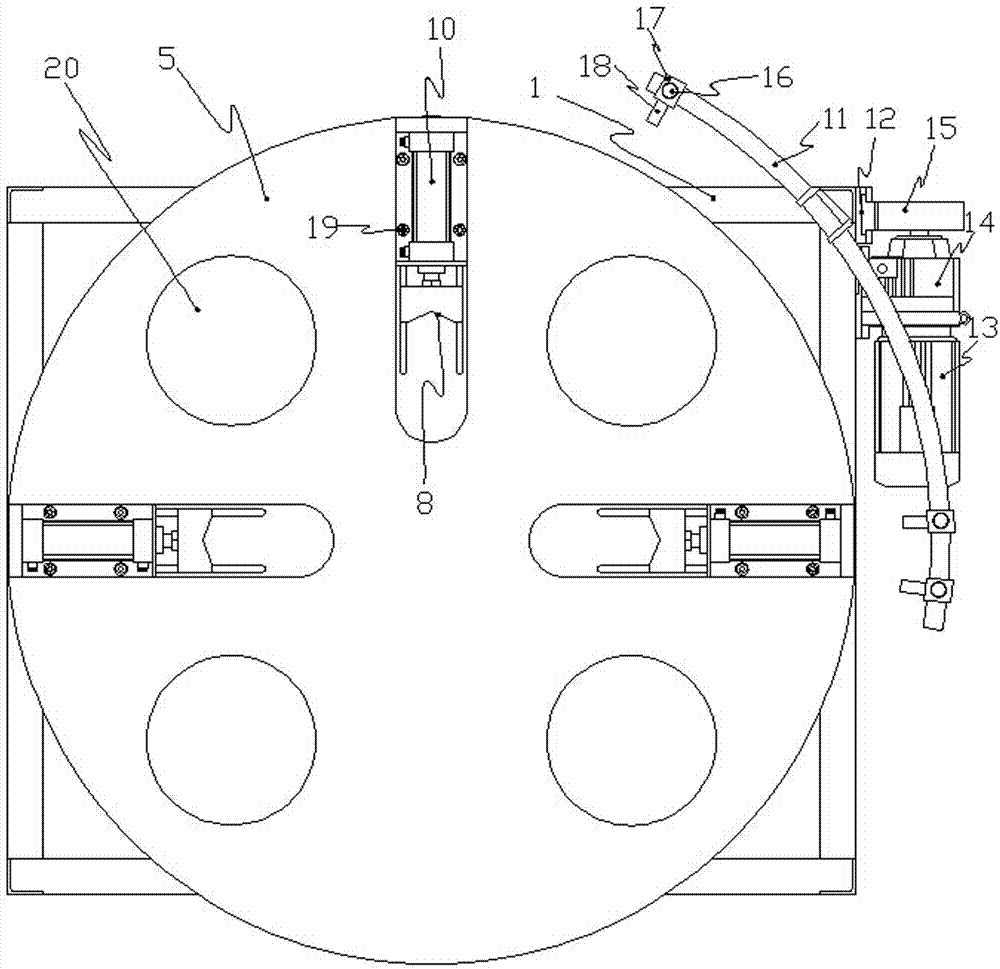

[0034] Regarding the reflective photoelectric sensor 18, also known as a reflective photoelectric switch, the common reflective infrared photoelectric sensor is a small photoelectric component that can detect changes in the light intensity it receives. In the early stage, it was used to detect whether the object was sensed. It is composed of an infrared emitting tube and an infrared receiving tube. Its emission wavelength is 780nm-1mm. The emitter has a calibration lens to focus the light on the Receiver, the receiver out cable connects this unit to a vacuum tube amplifier.

[0035] The detection object is when it enters the gap between the slotted switch and the block light path between the emitter and the detector, when the object approaches to the interrupter, the light collected by part of the receiver is reflected from the object to the photoelectric element above. It uses the object to block or reflect the infrared beam, and detects the presence or absence of the object ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com