Overturn positioning device for batten machining and operation method of overturn positioning device

A technology for positioning devices and wooden strips, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., and can solve problems such as the inability to process multiple wooden strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

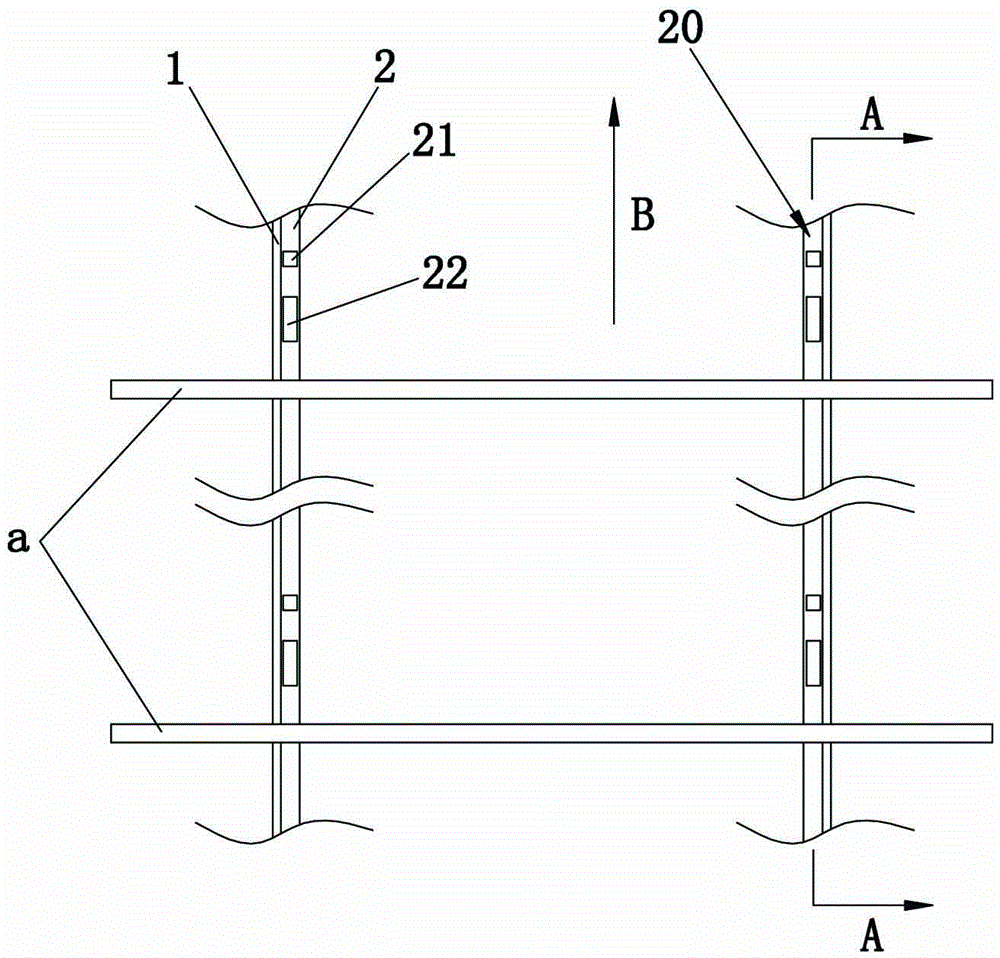

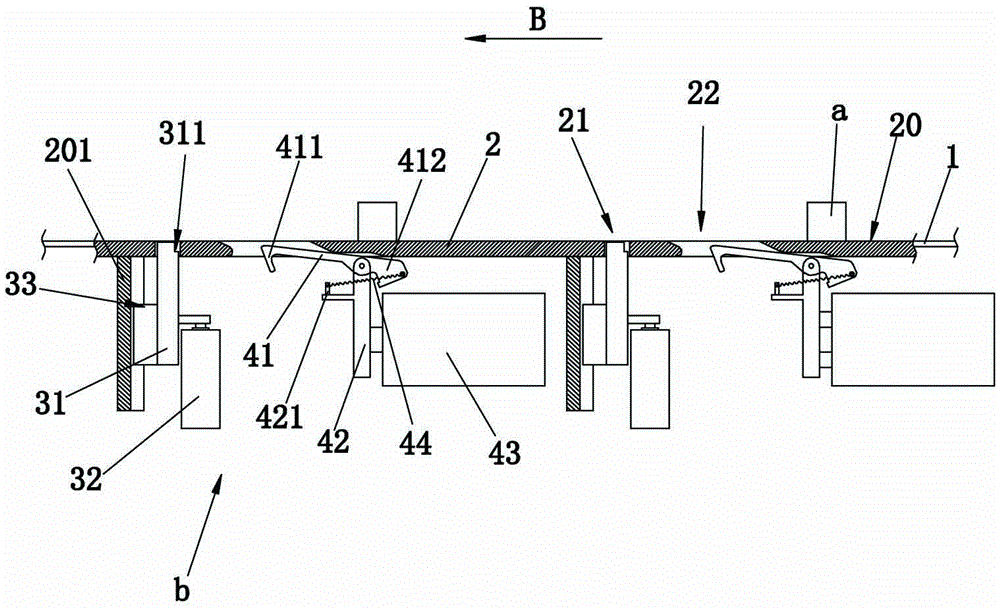

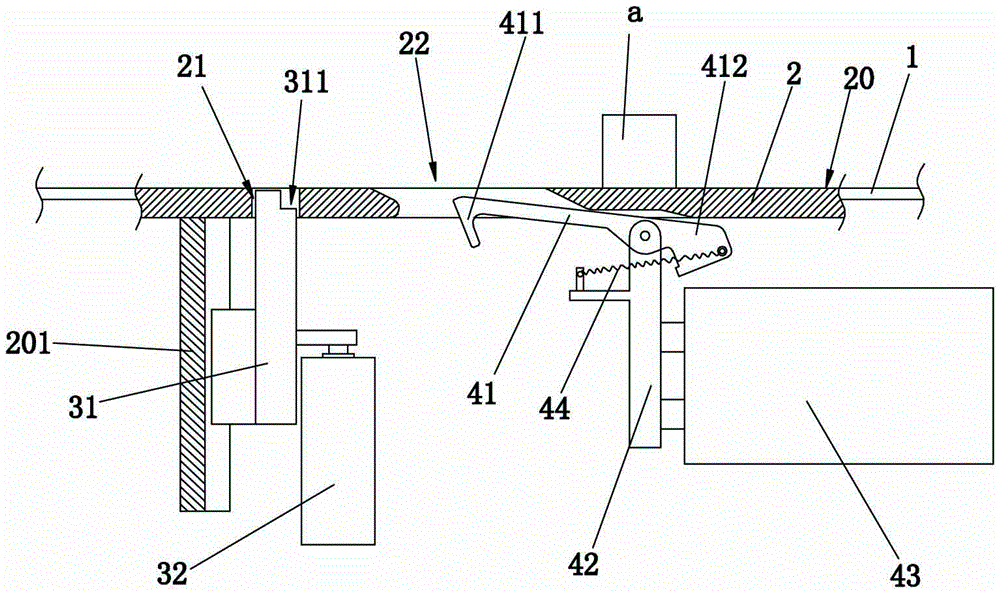

[0031] refer to figure 1 and figure 2 , a turning positioning device for wood strip processing, including a work surface 20, the work surface 20 is provided with a conveying mechanism for horizontally transporting the wood strip a on the work surface 20 along the vertical direction of the length of the wood strip. The working surface 20 is provided with at least one overturning positioning mechanism b along the conveying direction of the conveying mechanism. The overturning positioning mechanism b includes an overturning assembly for turning the wooden strip a by 90° and a positioning assembly for fixing the wooden strip.

[0032] refer to figure 1 , figure 2 and image 3 The above-mentioned overturning assembly includes a overturning lever 31 and a first driving device 32 that moves the overturning lever 31 to lift the front end of the wooden stick and cooperates with the above-mentioned conveying mechanism to turn the wooden stick a by 90°. The positioning assembly in...

Embodiment 2

[0037] refer to figure 1 and Figure 7 , a turning positioning device for wood strip processing, including a work surface 20, the work surface 20 is provided with at least one conveyor belt 1 for horizontally conveying the wood strip a on the work surface 20 along the vertical direction of the length of the wood strip. The working surface 20 is provided with at least one overturning positioning mechanism b along the length direction of the conveyor belt 1 . The overturning positioning mechanism b includes an overturning assembly for turning the wooden strip a by 90° and a positioning assembly for fixing the wooden strip.

[0038] refer to figure 1 , Figure 7 and Figure 8 , the above-mentioned overturning assembly includes a overturning lever 50 and a first drive device that makes the overturning lever 50 act to lift the front end of the wooden stick and cooperate with the conveyor belt 1 to turn the wooden stick a by 90°. The positioning assembly includes a positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com