Bottle washing machine and control method thereof

A control method and technology for a bottle washing machine, which are applied to conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of poor operation reliability, numerous electrical components and detection components, and complex structure and configuration. Reliable operation with few control elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Embodiments of the present invention are described in detail below:

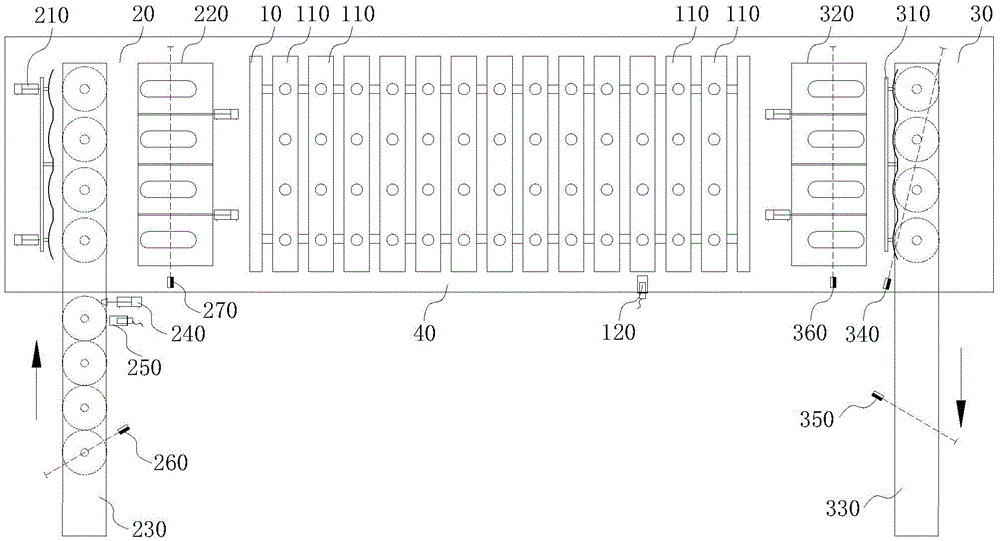

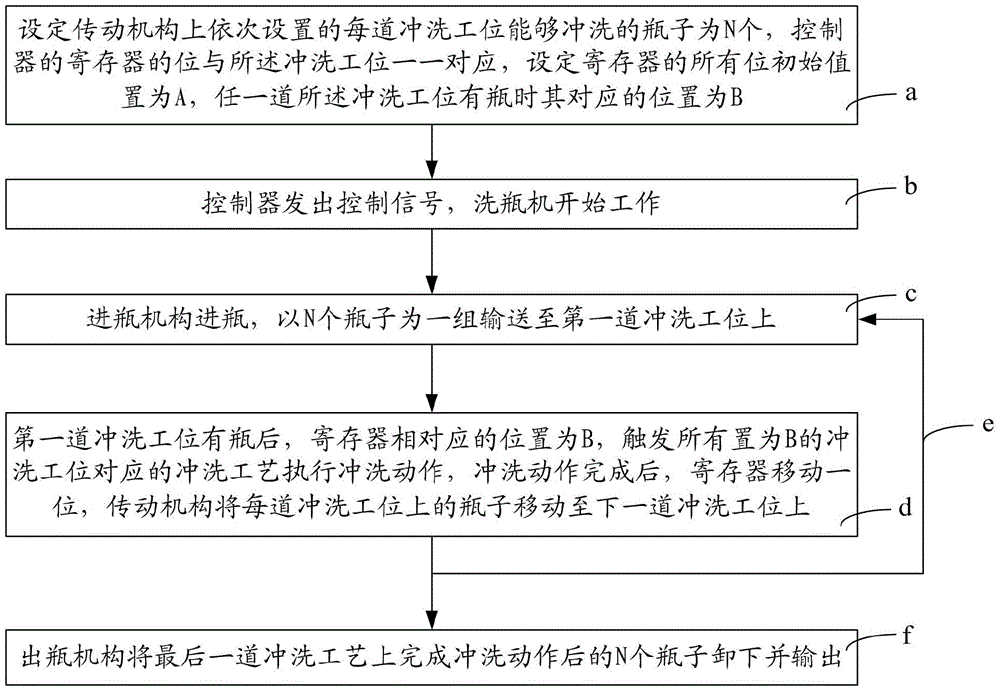

[0038] Such as figure 1 As shown, a bottle washing machine includes a transmission mechanism 10, a bottle inlet mechanism 20, a bottle outlet mechanism 30 and a controller electrically connected to the above-mentioned mechanisms respectively. The transmission mechanism 10 is sequentially provided with a plurality of washing stations 110, Described controller comprises register, and the position of described register corresponds to described flushing station 110 one by one, and the initial value of all bits of setting register is placed as A, and the corresponding position when a certain road described flushing station 110 has bottle is B, when the position corresponding to the first flushing station 110 is B, the controller is triggered to control all the flushing processes corresponding to the flushing station 110 set to B to perform the flushing action, and after the flushing action is completed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com