Automatic detection and adjustment device and method for preventing breakage and slippage of long-conveying-distance conveying belt

An automatic adjustment device and automatic detection technology, applied in conveyor control devices, transportation and packaging, conveyor objects, etc., can solve the problems of lack of pre-judgment ability and timely adjustment ability, low degree of automation, etc., and achieve rapid adjustment and automation. High, improve real-time and accuracy, break and slip phenomenon prevention adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

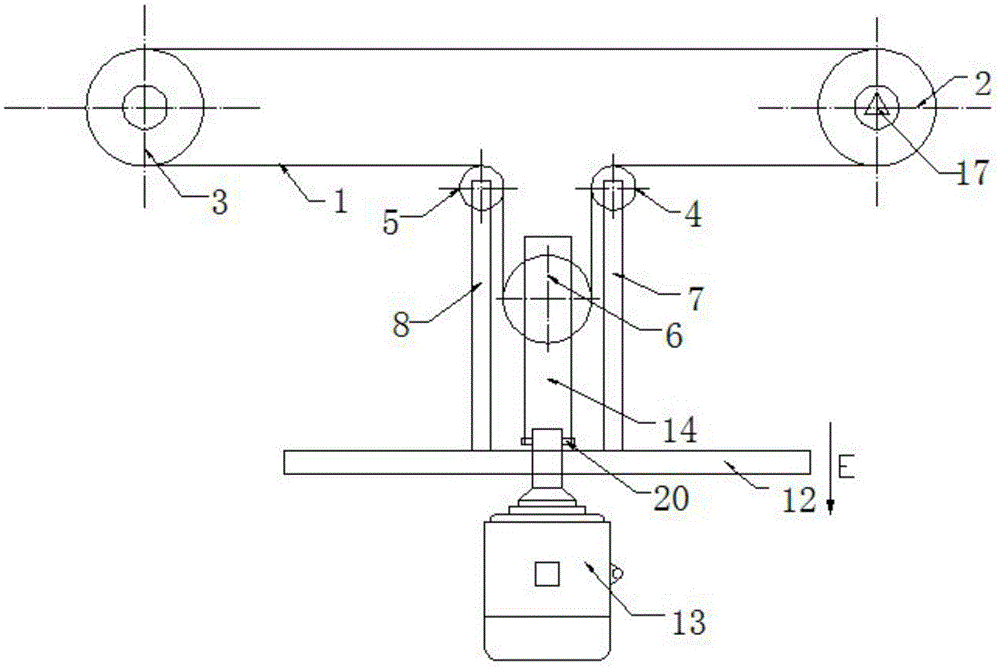

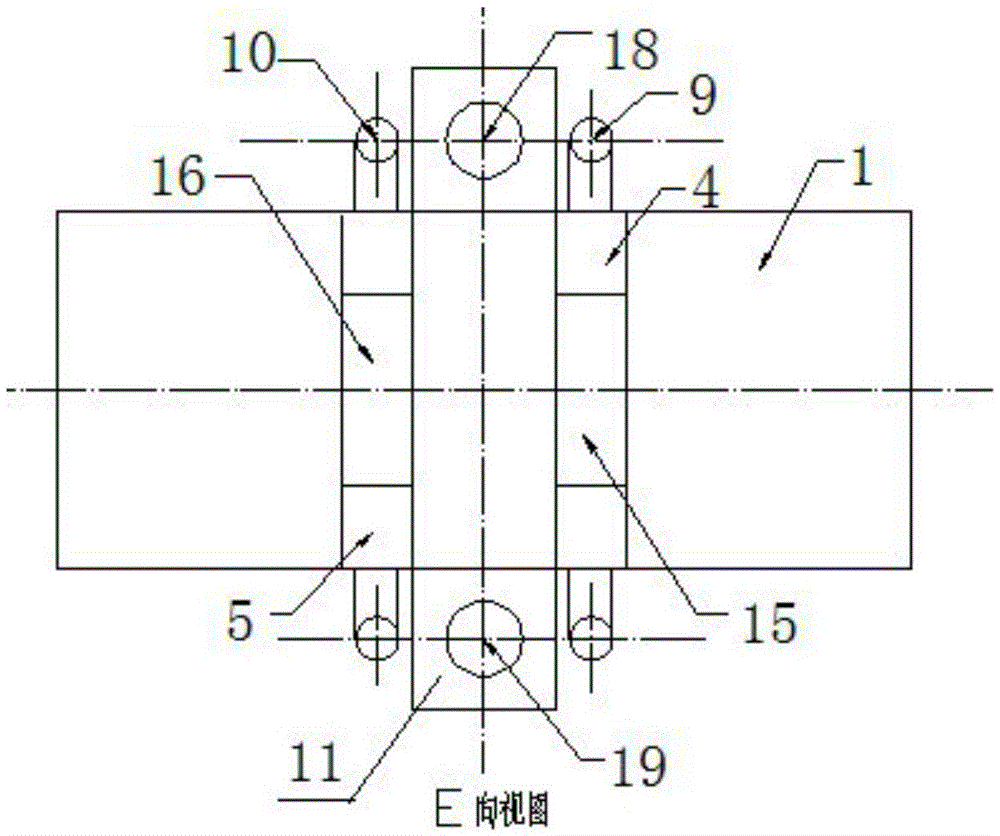

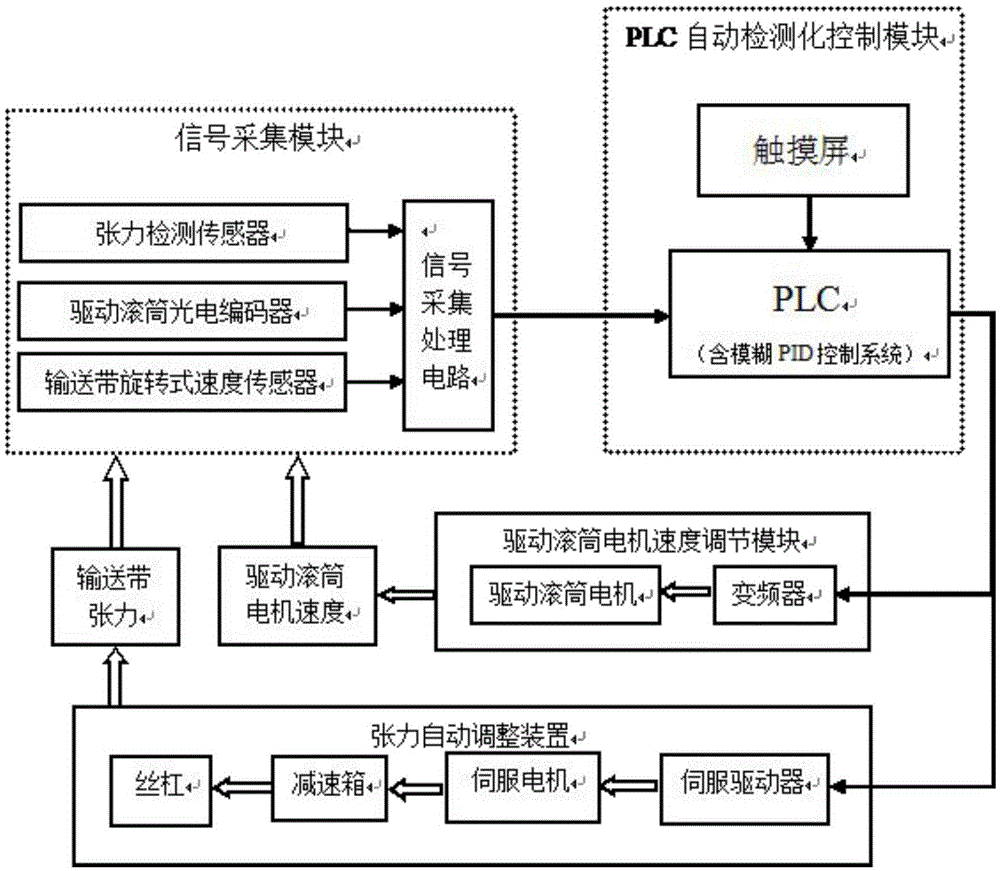

[0049] figure 1 with figure 2 Shown is an embodiment of the automatic detection and adjustment device for preventing breakage and slippage of long-distance conveyor belts according to the present invention. The automatic detection and adjustment device for preventing breakage and slippage of long-distance conveyor belts includes a mechanical part and a measurement and control part.

[0050] The mechanical part includes a conveyor belt 1, a transmission system, a driving roller 2, a reversing roller 3, a conveyor belt tensioning mechanism, a supporting mechanism and an automatic tension adjustment device; the conveyor belt 1 is wound around the driving roller 2 and the Between the reversing rollers 3, the transmission system includes a driving roller motor connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com