Magnetic-levitation train levitation control device and method

A technology of suspension control and maglev trains, which is applied to electric vehicles, vehicle components, transportation and packaging, etc., can solve the problems of high cost and vehicle structure no longer adapting to the original line conditions, and achieve large volume and good comprehensive effect , the effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

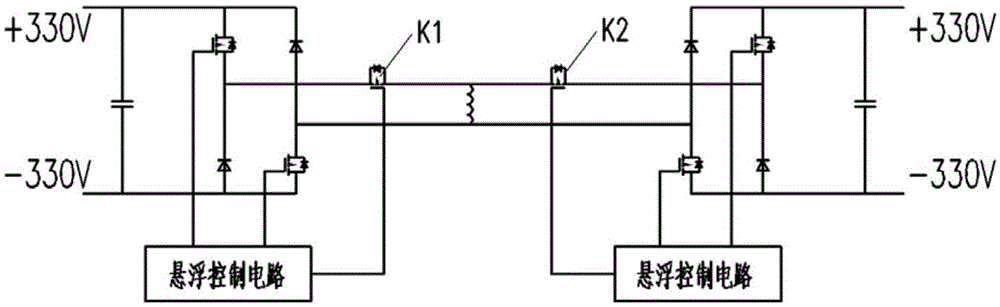

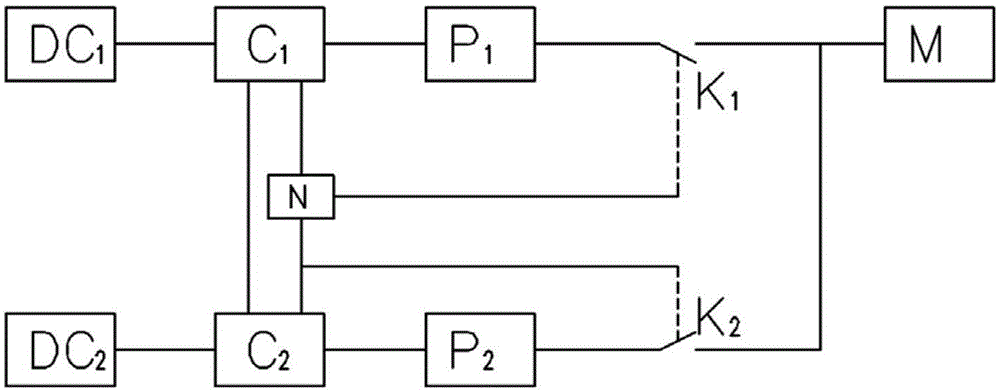

[0030] Such as figure 2 , image 3 As shown, a levitation control device for a maglev train is used to control the electromagnet of the maglev train. It includes two control units with the same structure and independent electricity. Switches K1, K2, power conversion circuits P1, P2 for generating the electromagnet current, auxiliary power supplies DC1, DC2 for supplying power to the control circuits C1, C2 and power conversion circuits P1, P2, the auxiliary power supplies DC1, DC2 are The mutually independent 660V DC power supplies supply power to the corresponding control circuits C1, C2 and power conversion circuits P1, P2 respectively. The output terminals of the power conversion circuits P1 and P2 are connected to the strobe power switches K1 and K2, the output power of the power conversion circuits P1 and P2 is controlled by the control circuits C1 and C2 of the control unit where they are located, and the strobe power switches K1 and K2 are fully controlled Electronic...

Embodiment example

[0035]H-type power conversion circuits P1 and P2 are respectively composed of charging circuit, input side support capacitor, discharge circuit, IGBT or MOSFET fully controlled power device and freewheeling diode; the main control chips of control circuits C1 and C2 adopt DSP and FPGA, The main function is to receive the suspension sensor signal on the electromagnet, calculate the expected current value of the electromagnet according to a certain control algorithm, and generate a PWM signal, which is output to the drive board of the H-type power conversion circuit. Among the two strobe power switches K1 and K2, the strobe power switch K1 can be opened or closed by the joint control of the control circuit C1 and C2. When the control circuit C1, the power conversion circuit P1 and the auxiliary power supply DC1 are all normal, the strobe power switch K1 is controlled by the control circuit C1. When any one of the control circuit C1, the power conversion circuit P1 and the auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com