Assembling device for micron-size axle and hole

An assembly device and micron-level technology, which is applied in the direction of photographic devices, assembly machines, metal processing equipment, etc., can solve the problem of not being able to realize the bonding of micro-shafts and micro-holes, and cannot meet the needs of visual observation of micron-level shaft and hole space assembly, Problems such as the inability to realize the detection of spatial relative poses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

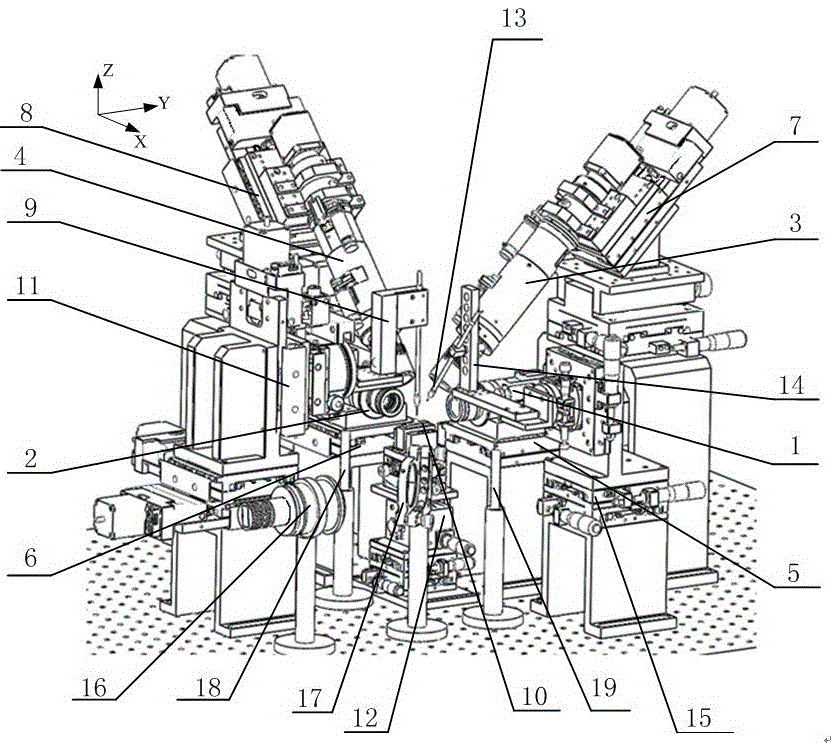

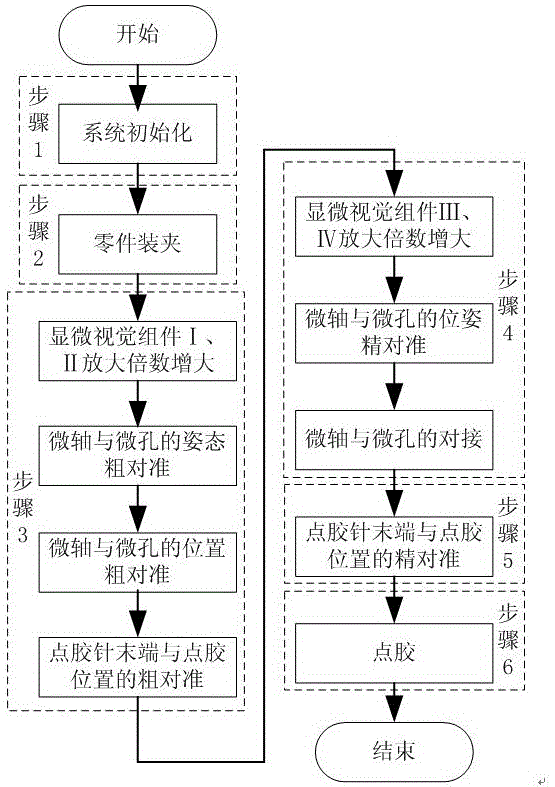

[0043] In the embodiment, the micro vision component I1, the micro vision component II2, the micro vision component III3, and the micro vision component IV4 are all composed of the TXG50C camera of the Swiss company Baumer and the variable magnification microscope lens of the American Navitar company. The magnifications of micro vision unit Ⅰ1 and micro vision unit Ⅱ2 are 1.74~21, and the magnifications of micro vision unit Ⅲ3 and micro vision unit Ⅳ4 are 5.54~66.63. The angle between the optical axes of the micro vision component III3 and the micro vision component I1 is 60°, and the angle between the optical axes of the micro vision component IV4 and the micro vision component II2 is 60°. Both the microvision position adjustment mechanism I5 and the microvision position adjustment mechanism II6 include a one-dimensional electric position adjuster along the optical axis direction, which are respectively used for the microvision component I1 and the microvision component II2 al...

Embodiment 2

[0068] The implementation of embodiment 2 is basically the same as that of embodiment 1, the main difference is that the angle between the optical axes of the micro vision component III3 and the micro vision component I1 is 45°, and the optical axis of the micro vision component IV4 and the micro vision component II2 The included axis angle is 45°. The micro-shaft at the end of the micro-shaft part and the micro-hole at the top of the micro-hole part are clearance fit, and the range of the fit clearance is 0.5 μm.

Embodiment 3

[0070] The implementation of embodiment 3 is basically the same as that of embodiment 1, the main difference is that the angle between the optical axes of the micro vision component III3 and the micro vision component I1 is 70°, and the optical axis of the micro vision component IV4 and the micro vision component II2 The included axis angle is 70°. The micro-shaft at the end of the micro-shaft part and the micro-hole at the top of the micro-hole part have a clearance fit, and the range of the fit clearance is 1.5 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com