Preparing and cutting method for textured nickel-tungsten alloy composite base band

A technology of nickel-tungsten alloy and composite base tape is applied in the field of preparation and shearing of textured nickel-tungsten alloy composite base tape, which can solve the problems of broken tape, large burrs, small edge waves, etc., so as to reduce the number of edge trimming and avoid breaking Belt, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

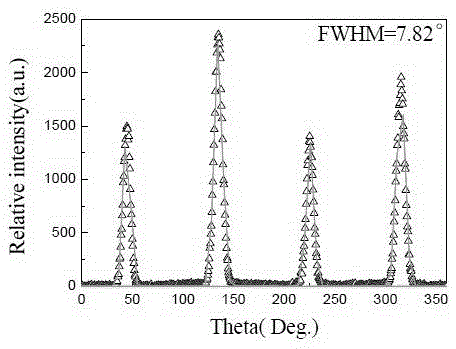

Image

Examples

Embodiment 1

[0018] Step S100: cold rolling the nickel-tungsten alloy and cutting the cracked edge

[0019] Step S101: Cold rolling the nickel-tungsten alloy ingot with a tungsten atomic percentage of 5.5% obtained by hot rolling from 7 mm thick to 1.6 mm thick with a width of 320 mm using a four-roll cold rolling mill;

[0020] Step S102: Trimming the initial nickel-tungsten alloy baseband obtained in step S101 with a disc shear. The trimming width on both sides of the alloy base strip is 2mm;

[0021] Step S103: Continue cold rolling the initial nickel-tungsten alloy base strip after the shearing treatment in step S102 to 95 μm;

[0022] Step S104: Use a tension-free disc shear to cut and crack the edge of the cold-rolled nickel-tungsten alloy base strip treated in step S103. The specific process parameters are that the gap between the upper and lower disc knives on one side is 8 μm, and the blade overlap is 50 μm. The trimming width on both sides of the cold-rolled nickel-tungsten all...

Embodiment 2

[0028] Step S100: cold rolling the nickel-tungsten alloy and cutting the cracked edge

[0029] Step S101: Cold rolling the nickel-tungsten alloy ingot with a tungsten atomic percentage of 6.3% obtained through hot rolling with a four-roll cold rolling mill from a thickness of 7 mm to a thickness of 1.6 mm and a width of 300 mm;

[0030] Step S102: Trimming the initial nickel-tungsten alloy baseband obtained in step S101 with a disc shear. The trimming width on both sides of the alloy base strip is 4mm;

[0031] Step S103: Continue cold rolling the nickel-tungsten alloy base strip after the shearing treatment in step S102 to 95 μm;

[0032] Step S104: Use a tension-free disc shear to cut and crack the edge of the cold-rolled nickel-tungsten alloy base strip treated in step S103. The specific process parameters are that the gap between the upper and lower disc knives on one side is 10 μm, and the blade overlap is 70 μm. The trimming width on both sides of the cold-rolled nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com