Corrugated plate type denitration catalyst unit assembling platform and assembling method

A denitrification catalyst and unit assembly technology, which is applied to chemical instruments and methods, separation methods, and dispersed particle separation, can solve the problems of large space occupation, low efficiency, waste, etc., and achieve improved assembly efficiency, high operating flexibility, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

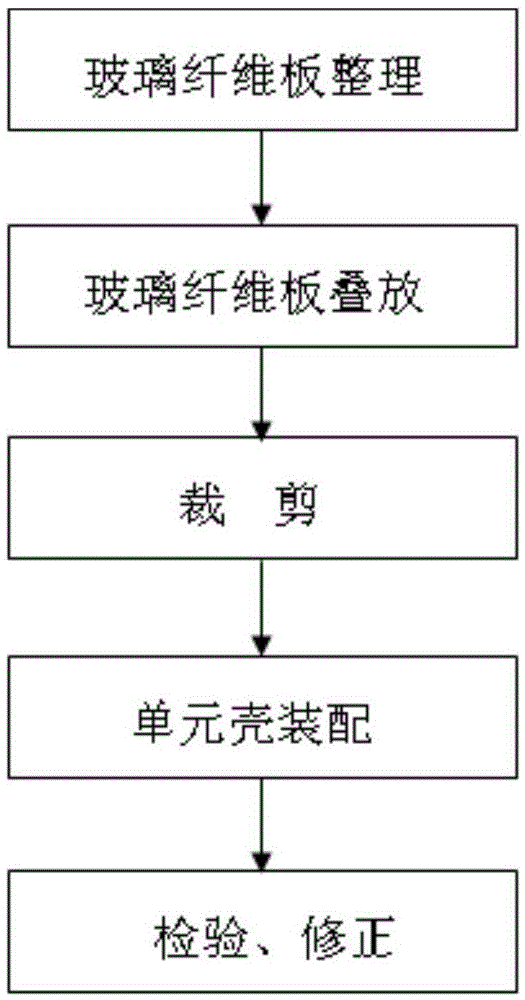

[0058] A method for assembling a corrugated denitration catalyst unit, comprising the following steps:

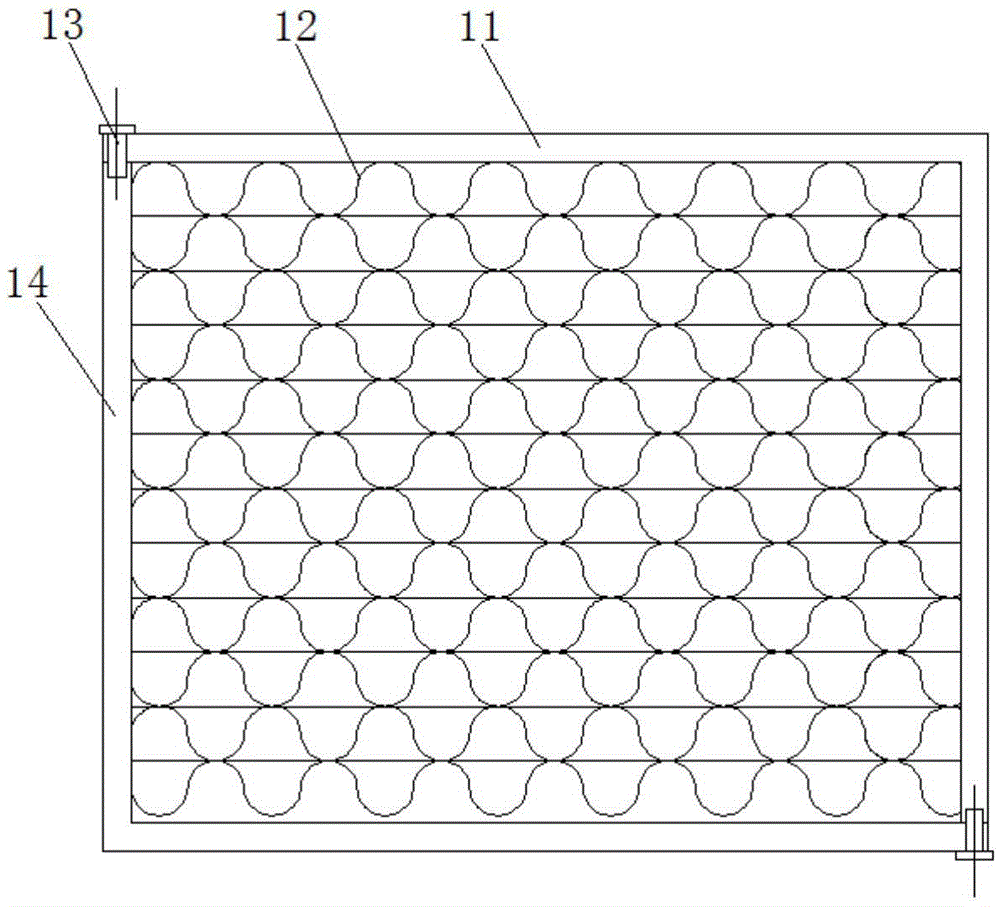

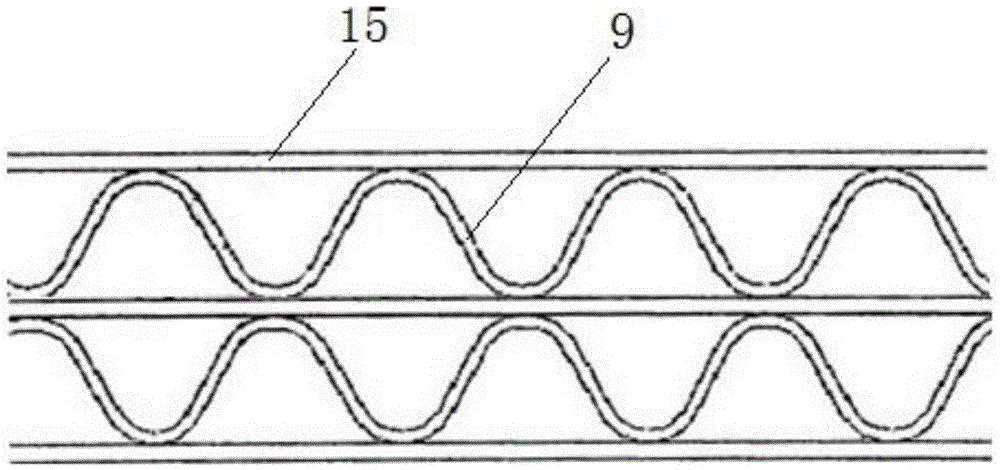

[0059] 1. Select the glass fiber corrugated board 9 that meets the quality requirements and arrange it: put the 550mm wide glass fiber original roll into the glass fiber molding equipment for glass fiber molding, and form a set of 500mm×550mm corrugated board and 461mm×550mm flat plate for assembly The raw material is to select burr-free and non-deformed glass fiber corrugated boards 9 , and place them according to the corrugated boards' crest upwards and corrugated boards' troughs upwards.

[0060] 2. Treat the glass core fiberboard with burrs with smooth iron wire and put it into use.

[0061] 3. Send to the corrugated plate type denitration catalyst assembly platform, place the glass fiber corrugated plates (about 100 pieces) with upward crests on the sliding plate (6) of the catalyst assembly platform, and place the glass fiber corrugated plates (about 100 pieces) with ...

Embodiment 2

[0067] A method for assembling a corrugated denitration catalyst unit, comprising the following steps:

[0068] 1. Select the glass fiber corrugated board 9 that meets the quality requirements and arrange it: put the 550mm wide glass fiber original roll into the glass fiber molding equipment for glass fiber molding, and form a set of 500mm×550mm corrugated board and 461mm×550mm flat plate for assembly The raw material is to select burr-free and non-deformed glass fiber corrugated boards 9 , and classify and place them according to the corrugated boards with corrugated boards facing upwards and the corrugated boards facing upwards.

[0069] 2. Treat the glass core fiberboard with burrs with smooth iron wire and put it into use.

[0070] 3. Send it to the corrugated denitration catalyst assembly platform, place the glass fiber corrugated plates (about 100 sheets) with upward wave crests on the sliding plate 6 of the catalyst assembly platform, and place the glass fiber corrugate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com