Liquid net dust collector

A dust collector and dust chamber technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve the problems of factory operation schedule discount, occupying more time, filter cartridge clogging, etc., to improve operation continuity, The effect of high promotion value and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

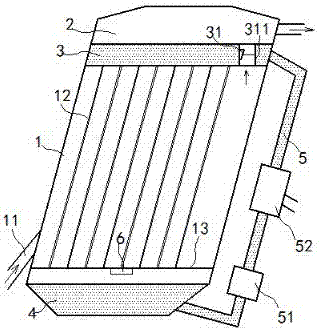

[0013] in figure 1 In the illustrated embodiment, the liquid cleaner includes a dust removal chamber 1 and a purification chamber 2. The purification chamber 2 is placed above the dust removal chamber 1; an air inlet pipe 11 is installed on the side wall of the dust removal chamber 1, and the cleaning chamber 2 An exhaust pipe is installed on the side wall of the dust removal chamber; the bottom of the dust removal chamber 1 is made of ferromagnetic material; the top of the dust removal chamber 1 is equipped with a liquid storage chamber 3, and the liquid storage chamber 3 is equipped with dust removal liquid; the dust removal chamber 1 passes An air duct 31 penetrating the liquid storage chamber 3 is connected to the purification chamber 2; a dust monitor 311 is installed in the air duct 31; and dust removal wires 12 are hung equidistantly on the bottom plate of the liquid storage chamber 3. The upper end of the dust removal wire 12 penetrates the bottom plate of the liquid st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com