Corn straw crushing device

A crushing device and technology of corn stalks, which are applied in the direction of balers, cutters, agricultural machinery and implements, etc., can solve the problems of size reduction, incapable of corn stalk bundling and coating operations, etc., and achieve convenient and fast crushing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

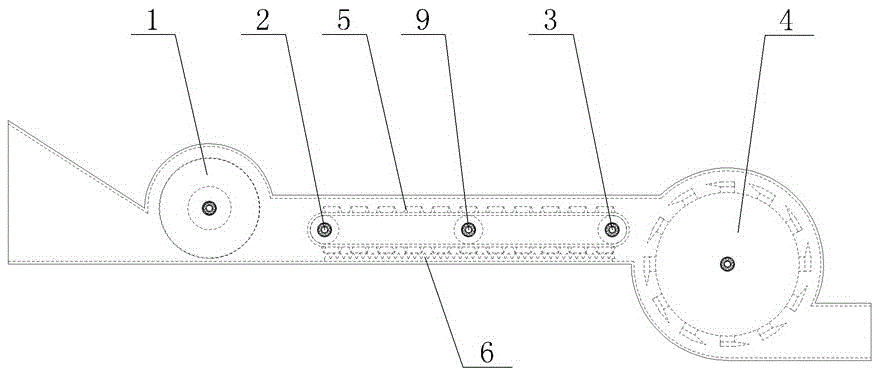

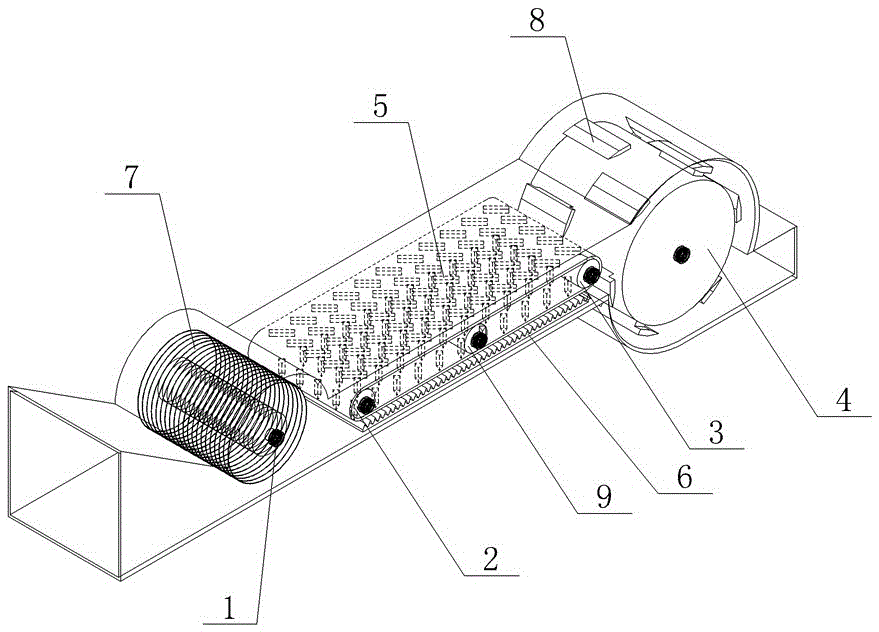

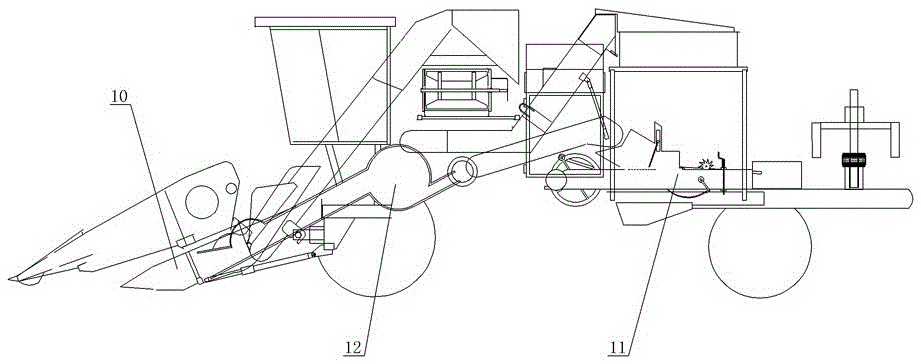

[0023] The corn stalk pulverizing device of present embodiment, as figure 1 and figure 2 As shown, it includes a housing, which is provided with a first rotating shaft 1, a driving shaft 2, a driven shaft 3, a second rotating shaft 4 arranged relatively parallel to each other, and a mobile rubbing plate 5 and a fixed rubbing plate arranged up and down relative to each other. board6.

[0024] The first rotating shaft 1 is located at the entrance of the crushing device, the second rotating shaft 4 is located at the exit of the crushing device, and the driving shaft 2 and the driven shaft 3 are located between the first rotating shaft 1 and the second rotating shaft 4 .

[0025] A longitudinal cutter 7 perpendicular to its centerline is fixed on the circumference of the first rotating shaft 1 , and a transverse cutter 8 parallel to its centerline is fixed on the circumference of the second rotation shaft 4 .

[0026] The mobile rubbing board 5 is a conveyor-belt-shaped rubbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com