Holding and supporting group of a winding spindle in a plastic film winding machine

A technology for supporting components and winding spools, applied in the direction of winding strips, thin material handling, transportation and packaging, which can solve the problems of time loss, incomplete clamping of the mandrel, and inability to ensure axial blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

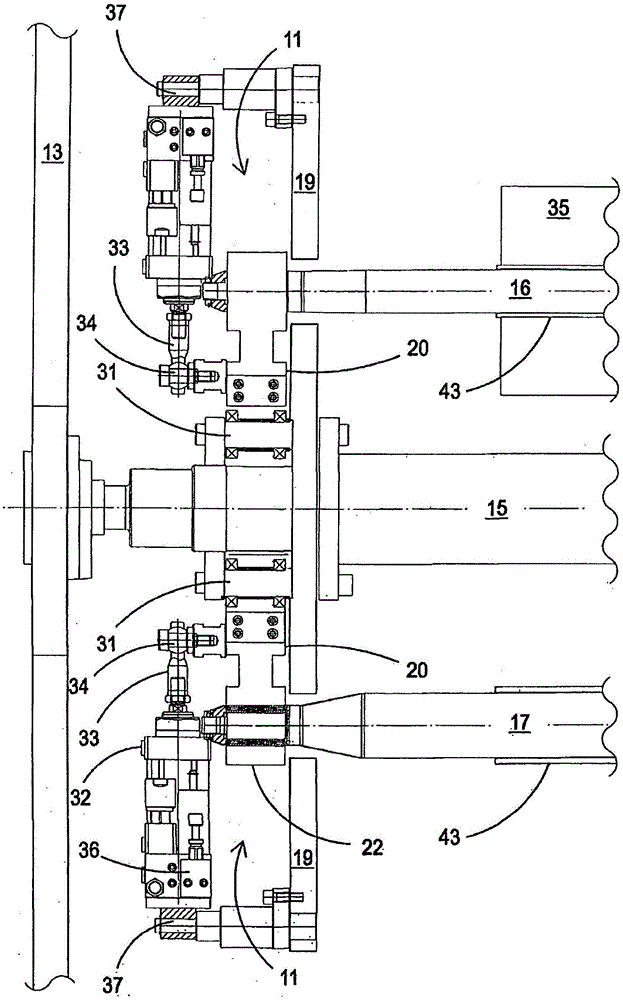

[0024] First refer to figure 1 , figure 1 An upright schematic side view showing a part of the winding machine in the area comprising the holding and supporting assembly 11 of the winding mandrel produced according to the invention is shown.

[0025] The holding and supporting assembly 11 is positioned inside two vertical uprights 12, 13 forming the shoulders of the winder. The first upright 12 carries cantilevered on a rotating support plate 14 a central shaft 15 which is supported at the other end corresponding to the second upright 13 .

[0026] The plate 14 rotating around the central axis 15 also carries three mandrels 16, 17 and 18, arranged at 120° relative to each other, which completely constitute the winding reel.

[0027] According to the invention, the holding and supporting assembly 11 of the winding mandrel produced according to the invention is associated with the reel.

[0028] Assembly 11 comprises a star plate 19 with three selective support arms of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com