Greenhouse aeroponics monitoring terminal

A monitoring terminal and greenhouse technology, applied in the direction of non-electric variable control, control/regulation system, simultaneous control of multiple variables, etc., can solve the problems of unfavorable plant effective growth, low degree of automation, waste of manpower and material resources, etc., to achieve effective plant growth. The effect of growth, low input cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

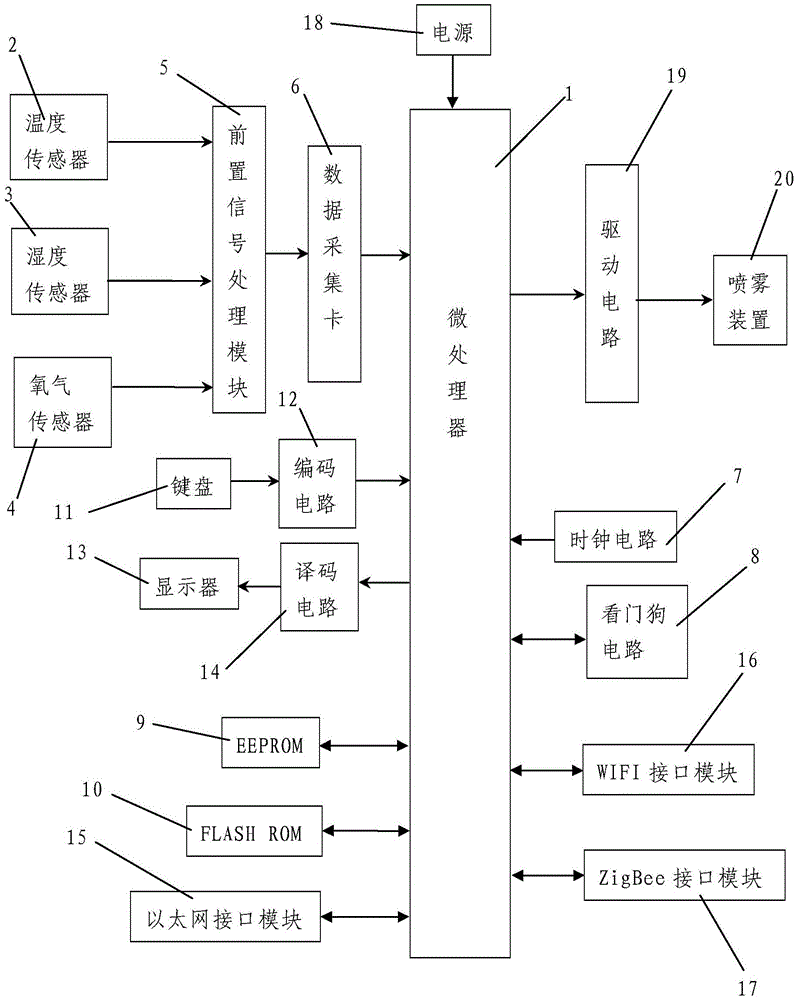

[0022] Such as figure 1 As shown, the present invention includes a microprocessor 1, a temperature sensor 2 for detecting the temperature of the greenhouse, a humidity sensor 3 for detecting the humidity of the greenhouse, and a humidity sensor 3 for detecting the oxygen concentration of the greenhouse. Oxygen sensor 4, the pre-processing module 5 for preprocessing the signals detected by the temperature sensor 2, humidity sensor 3 and oxygen sensor 4, collecting and transmitting data to the signal output by the pre-signal processing module 5 The data acquisition card 6 of the microprocessor 1, the clock circuit 7 used to provide real-time time for the microprocessor 1, the watchdog circuit 8 used to prevent the system failure from causing the microprocessor 1 to crash, and the EEPROM 9 used to store the system program , FLASHROM 10 for storing system parameters and historical data, encoding circuit 12 connected with keyboard 11 and microprocessor 1 respectively, decoding circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com