Scraping plate drum dryer

A drum scraper drying and scraper technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve problems such as uneven product quality and difficult adhesion process, and achieve uniform distribution and improved product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

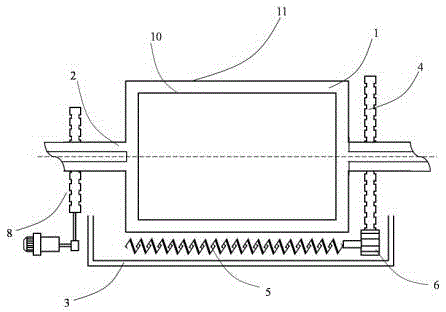

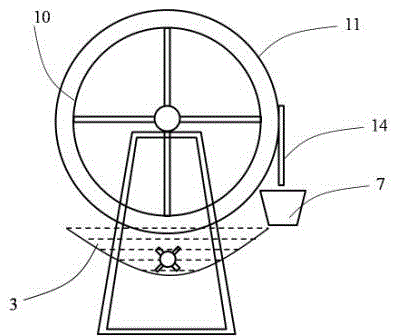

[0030] Drum scraper dryers, such as figure 1 and 2 As shown, it includes: drum shell 1 (length-to-diameter ratio 1.5), rotating shaft 2, power device 8 (including motor, reducer and gear), material liquid pan 3, scraper 14 and material slag collection device 7;

[0031] The drum body 1 is coaxial with the rotating shaft 2, and the rotating shaft 2 is connected to the power device 8; the liquid tray 3 is located below the drum body 1; the two ends of the drum body 1 are provided with mechanical seal heads;

[0032] Drum body 1: including an inner cylinder 10 and an outer cylinder 11, the inner cylinder 10 and the outer cylinder 11 are coaxial;

[0033] Feed liquid stirring device: the feed liquid stirring device includes a stirrer 5 and a stirring gear 4; the stirrer 5 is located above the feed liquid plate 3 and is parallel to the bottom of the feed liquid plate 3, and is used for stirring the feed liquid; the stirring gear 4 and the The rotating shaft 2 is connected; the st...

Embodiment 2

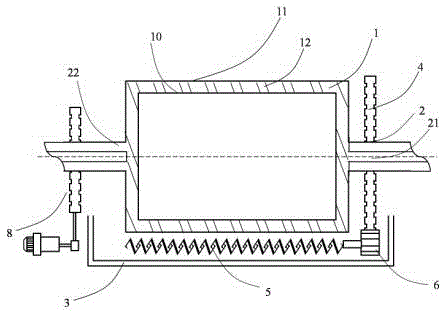

[0036] Drum scraper dryers, such as figure 2 , 3 As shown, it includes: drum body 1 (length-to-diameter ratio 1.8), rotating shaft 2, power device 8 (including motor, reducer and gear), material liquid plate 3, scraper 14 and material slag collection device 7;

[0037] The drum body 1 is coaxial with the rotating shaft 2, and the rotating shaft 2 is connected to the power device 8; the liquid tray 3 is located below the drum body 1; the two ends of the drum body 1 are provided with mechanical seal heads;

[0038]Drum body 1: includes an inner cylinder 10 and an outer cylinder 11, the inner cylinder 10 and the outer cylinder 11 are coaxial; between the inner cylinder 10 and the outer cylinder 11, a spiral deflector 12 is arranged to form a spiral oil guide groove;

[0039] Rotating shaft 2: The rotating shaft 2 is a double-layer hollow shaft; the inside is provided with an oil inlet channel 21 and an oil outlet channel 22 coaxially arranged with the drum body 1; the internal ...

Embodiment 3

[0043] Drum scraper dryers, such as figure 2 , 4 , 5, including: vacuum device 9, drum body 1 (length-to-diameter ratio 1.8), rotating shaft 2, power device 8 (including motor, reducer and gear), material liquid plate 3, scraper 14 and material slag collection device 7;

[0044] The drum shell 1, the feed liquid tray 3 and the scraper 14 are all located in the vacuum device 9, and the gas outlet 91 of the vacuum device 9 passes through a condenser and is connected to a gas collection tank;

[0045] The drum body 1 is coaxial with the rotating shaft 2, and the rotating shaft 2 is connected to the power device 8; the liquid tray 3 is located below the drum body 1; the two ends of the drum body 1 are provided with mechanical seal heads;

[0046] Drum body 1: including an inner cylinder 10 and an outer cylinder 11, the inner cylinder 10 and the outer cylinder 11 are coaxial;

[0047] Slag collection device 7: The slag collection device 7 includes a slag inlet 70, a slag channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com