clutch device

A clutch device and friction clutch technology, applied in transmission, transmission control, fluid transmission, etc., can solve problems such as poor efficiency, poor starting process, and troublesome emergency response, so as to improve efficiency and reduce losses. energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

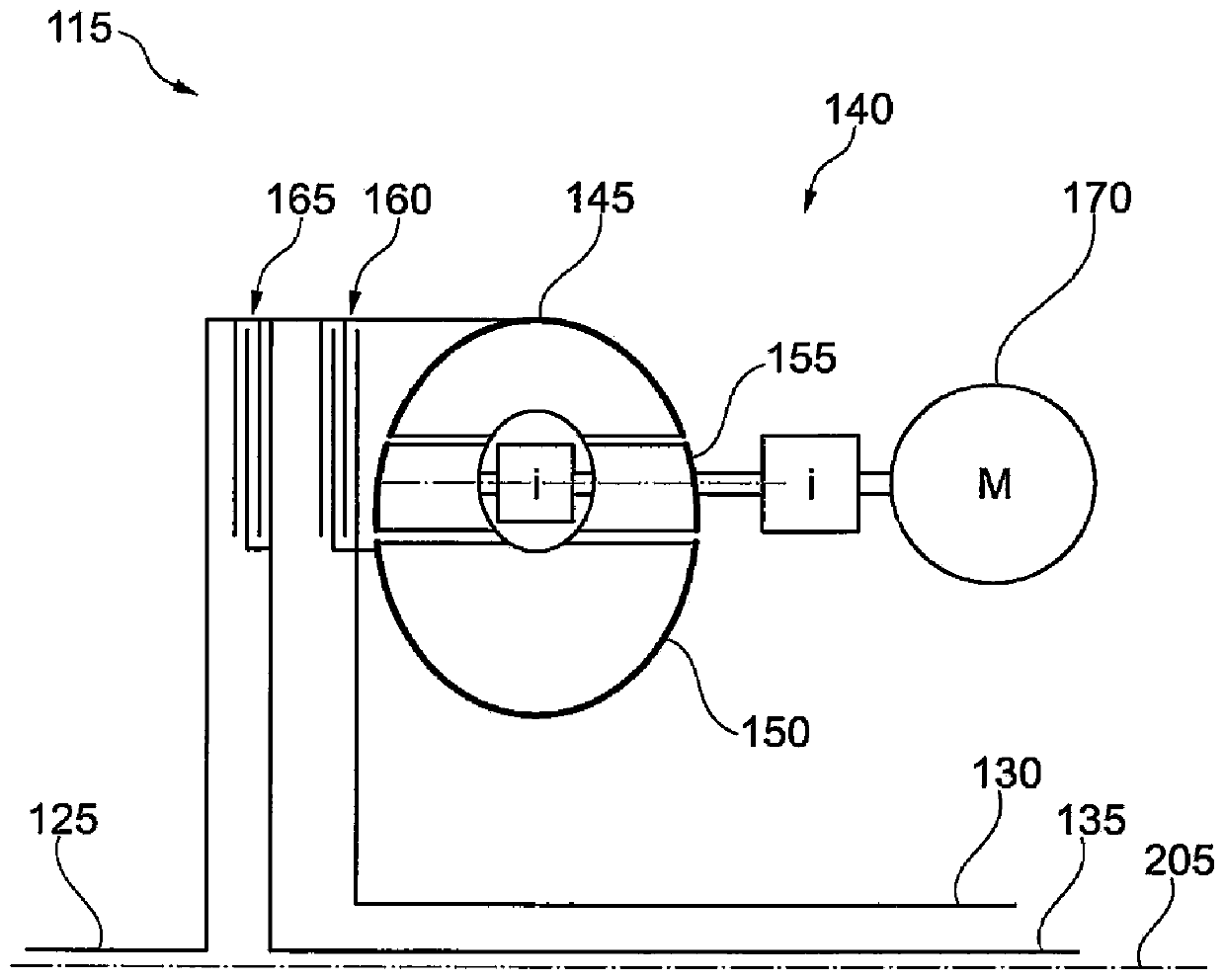

[0025] figure 1 A drive train 100 is shown, in particular for operation on a motor vehicle. The drive train 100 is configured to be mounted between a drive motor 105 and drive wheels 110 (both not shown). The drive train 100 here includes a clutch device 115 and a transmission 120 . The clutch device 115 includes an input side 125 and a first output side 130 and a second output side 135 , each for connection to an associated input shaft of the transmission 120 . The transmission 120 is preferably a double-shift transmission which is provided for engaging or disengaging different gears between the respective output sides 130 , 135 of the clutch device 115 and the shaft leading to the drive wheels 110 . A torque converter 140 is arranged between the input side 125 and the first output side 130 . Torque converter 140 includes an impeller 145 , a turbine 150 , and an stator 155 disposed generally between impeller 145 and turbine 150 . The stator 155 changes the flow of fluid b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com