Self-adjustable pipeline rectifying device

A rectifying device and self-adjusting technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems that the flow stability of the downstream pipeline cannot be improved, the flow performance cannot be adjusted well, and the safe operation of the pipeline and equipment is unfavorable. Ease of maintenance and operation, elimination of vibration phenomena, effect of rectifying fluid flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

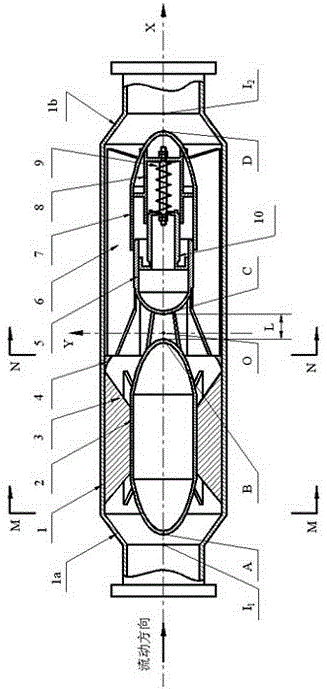

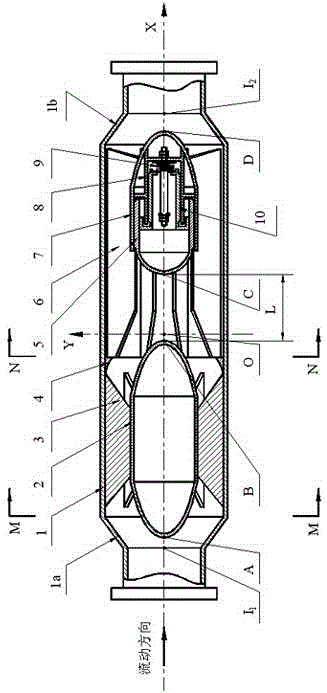

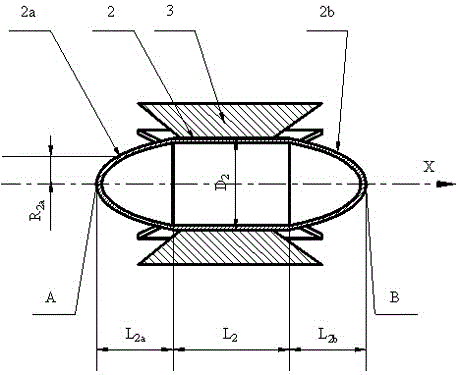

[0007] Such as figure 1 As shown, the self-adjustable pipeline rectification device of the present invention includes a rectification device cylinder body 1, and a rectification device inlet diameter expansion section 1a and a rectification device outlet diameter reduction section 1b, along the medium flow direction from front to rear, the rectification device cylinder The front rectifier body 2 and the rear rectifier body 7 are installed inside the body 1, and the front deflector 3 arranged evenly in the circumferential direction of the front rectifier body 2 is welded on the inner wall of the rectification device cylinder 1 and the outer wall surface of the front rectifier body 2, and the front rectifier body The rectifier body 2 is fixed inside the cylinder body 1 of the rectifier device, the guide ring 4 is installed behind the front guide plate 3, the rear rectifier body 7 is installed in the downstream direction of the guide ring 4, and the rear guide body is evenly arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com