Hinge-type valve installing structure in bag-type duster

A bag filter and installation structure technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of turbulent flow, affect ventilation effect, large pressure loss, etc., achieve simple structure, improve ventilation, etc. effect, the effect of reducing pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

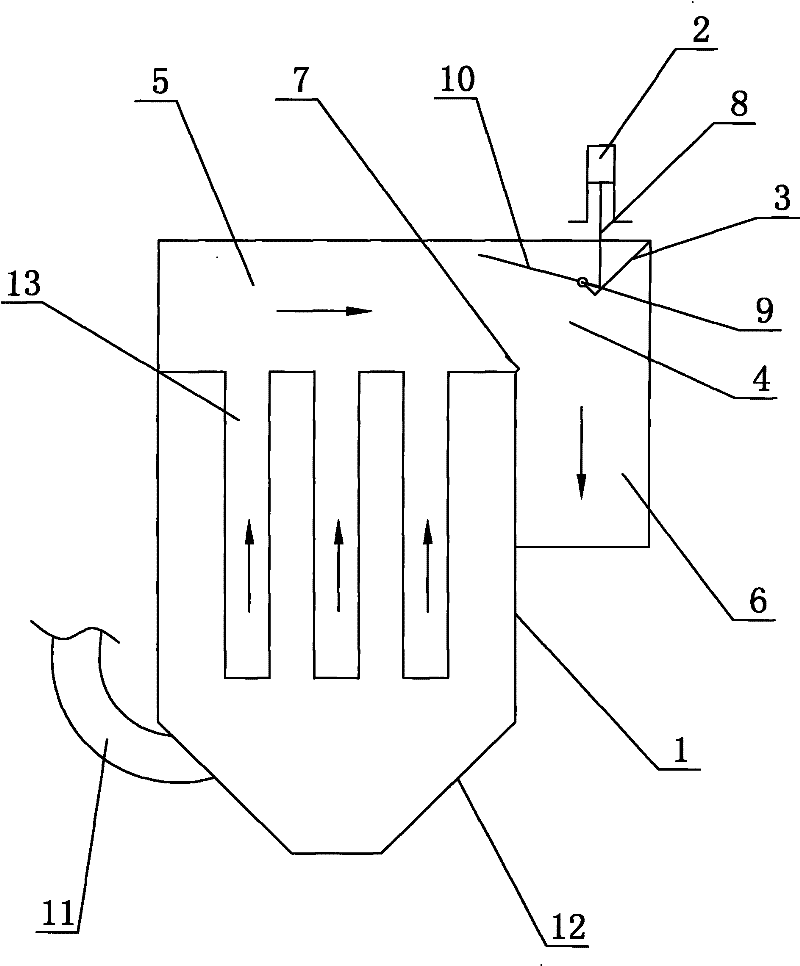

[0010] Such as figure 1 , figure 2 As shown, the installation structure of the hinged valve in the bag filter includes: a poppet valve 2 and an orifice plate 3 arranged on the upper end of the box body 1, and a vent hole 4 is arranged on the orifice plate 3, and the orifice plate 3 connects the box body 1 The upper end of the upper end is divided into two parts, the clean air chamber 5 and the air passage 6, and the orifice plate 3 is obliquely arranged on the box body 1 between the clean air chamber 5 and the air passage 6, and the outside of the air vent 4 is A retaining ring 7 is arranged on the orifice 3 , and a valve cover 10 cooperating with the retaining ring 7 is hinged on the valve stem 8 of the poppet valve 2 through a hinge shaft 9 .

[0011] Such as figure 1 As shown, when the installation structure of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com