Impeller of centrifugal fan

A centrifugal fan and impeller technology, applied in the mechanical field, can solve the problem of low connection stability and achieve the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

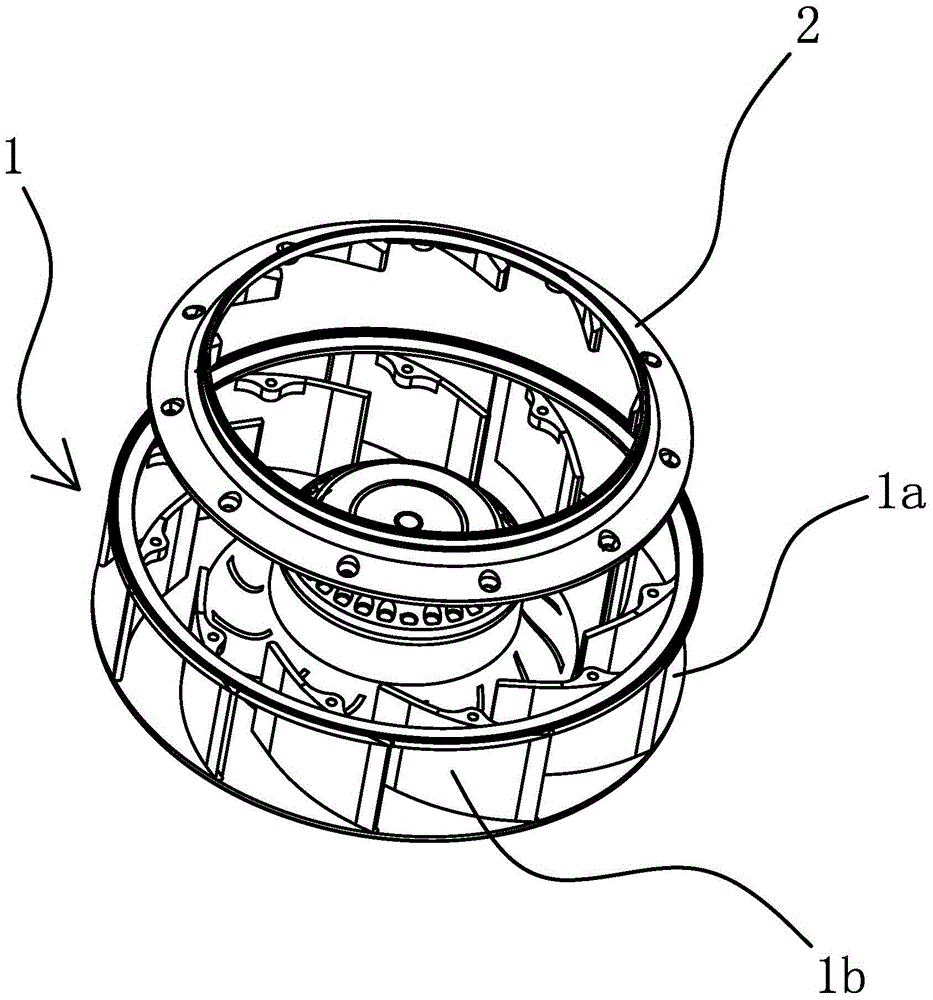

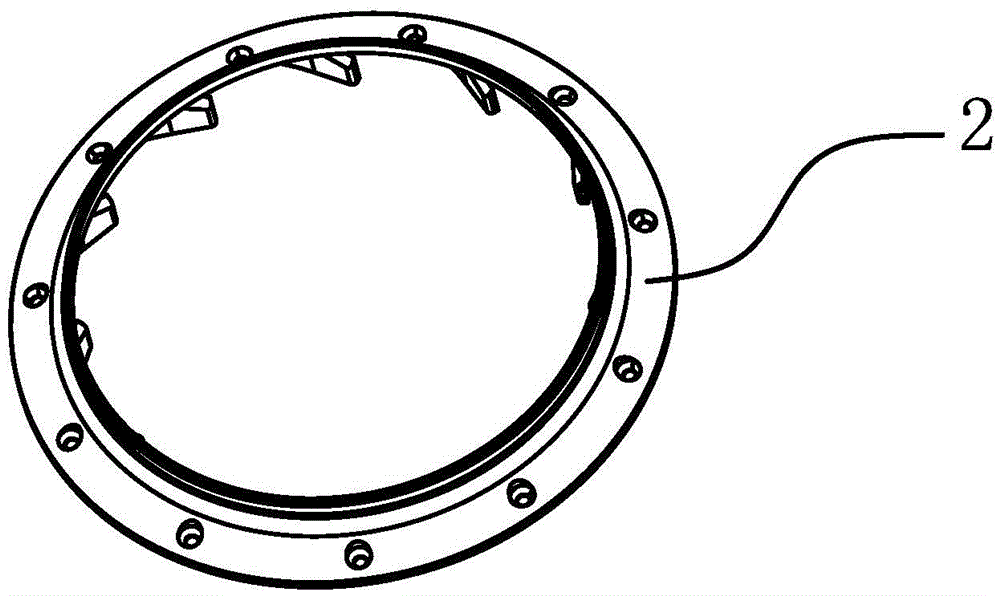

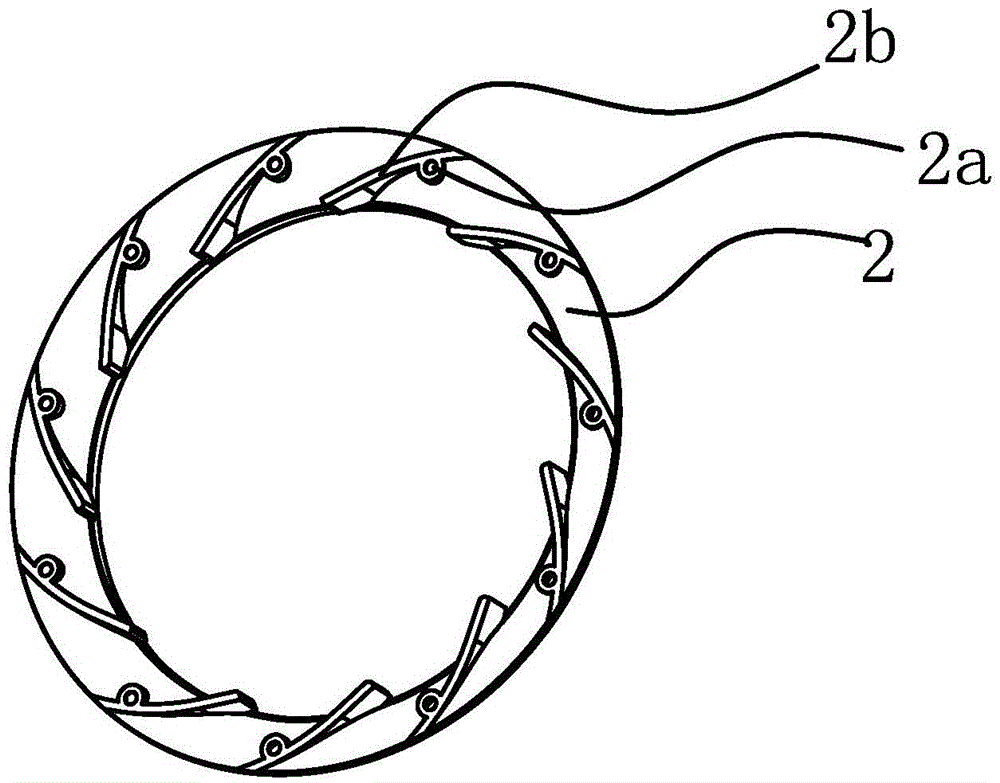

[0045] Such as figure 1 with figure 2 with image 3 with Figure 4 As shown, the impeller of the centrifugal fan includes an impeller body 1 and an end cover 2. The impeller body 1 includes a connecting seat 1a and several blades 1b. The above-mentioned blades 1b and the connecting seat 1a are of an integrated structure. The end cover 2 is a split structure, the inner edge of the above-mentioned blade 1b is connected with the connection seat 1a, the outer edge of the blade 1b has a connecting part 1, and the end cover 2 is circular and has a The first connecting part corresponds to the second connecting part, and the first connecting part and the second connecting part are connected by fasteners.

[0046] The number of the connecting part 1 and the connecting part 2 are the same, and the positions correspond to each other.

[0047] The first connecting part is a connecting block 1b1 protruding from the outer edge of the blade, and the connecting block 1b1 has a threaded h...

Embodiment 2

[0059] The structure of this embodiment is basically the same as that of the first embodiment, except that the impeller body and the end cover are made of magnesium alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com