Water-rich sandy cobble ground heteromorphosis deep shaft structural system and construction method thereof

A technology of sand and gravel and shaft, which is applied in shaft equipment, well sinking, earthwork drilling, etc., can solve the problem of lack of construction space, reduce unsafe factors, improve economic and social benefits, and avoid occupying area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

[0029] The invention provides a novel deep shaft construction concept, which enriches the existing shaft construction technology and broadens the deep shaft design thinking. Utilizing the design concept of combining special-shaped deep shafts and mining method tunnels, it can meet the stringent requirements of specific construction conditions for engineering schemes, and provides a brand new solution to ensure reasonable engineering schemes, controllable engineering risks and construction schedules, and engineering quality, safety and reliability. train of thought.

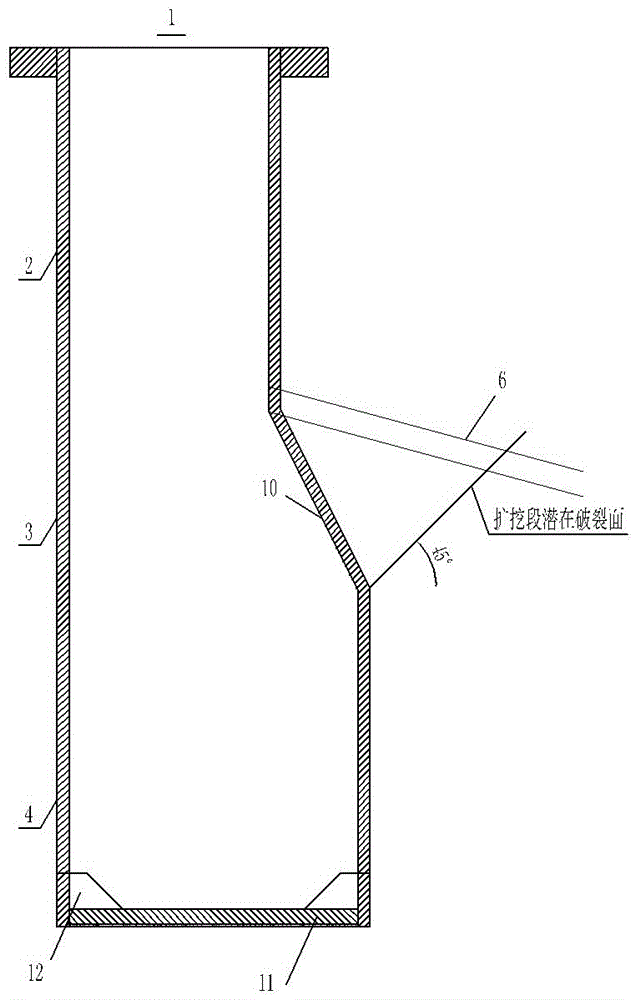

[0030] The special-shaped deep shaft structure system of the water-rich sand and pebble stratum involved in the present invention includes a special-shaped deep shaft structure 1, and the special-shaped deep shaft structure 1 includes a vertical shaft structure 2 with a triangular section from top to bottom, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com