A composite guide rail type tensile and vibration isolation rubber bearing

A vibration-isolation rubber and rail-type technology, which is applied in the direction of earthquake-proof, building components, construction, etc., can solve the problem of easy displacement, affect the horizontal vibration-isolation effect of vibration-isolation rubber bearings, reduce the performance and life of vibration-isolation rubber bearings, etc. problem, to achieve the effect of improving the vertical tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

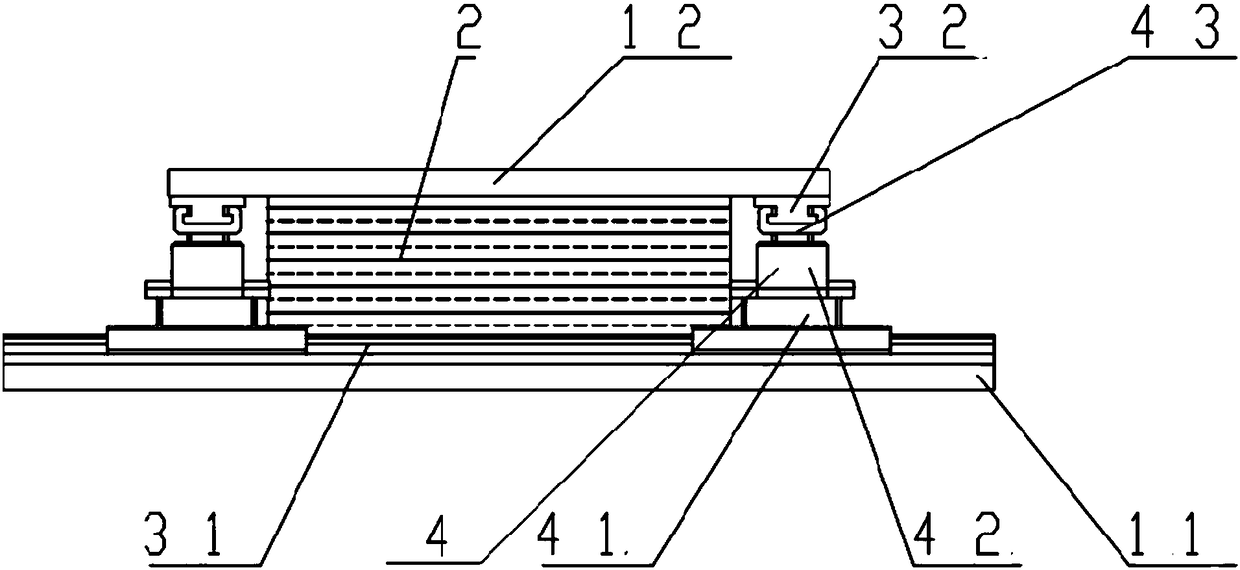

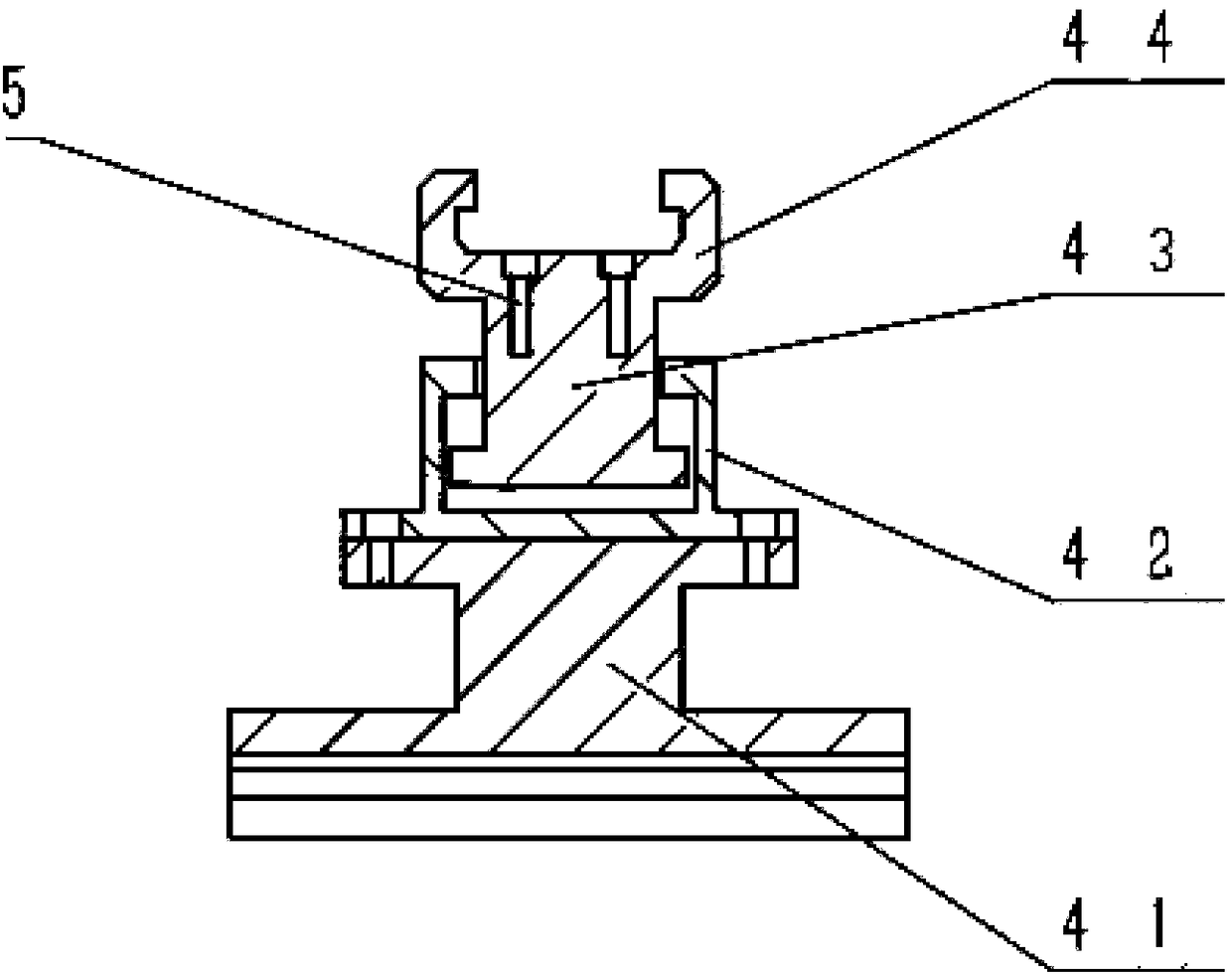

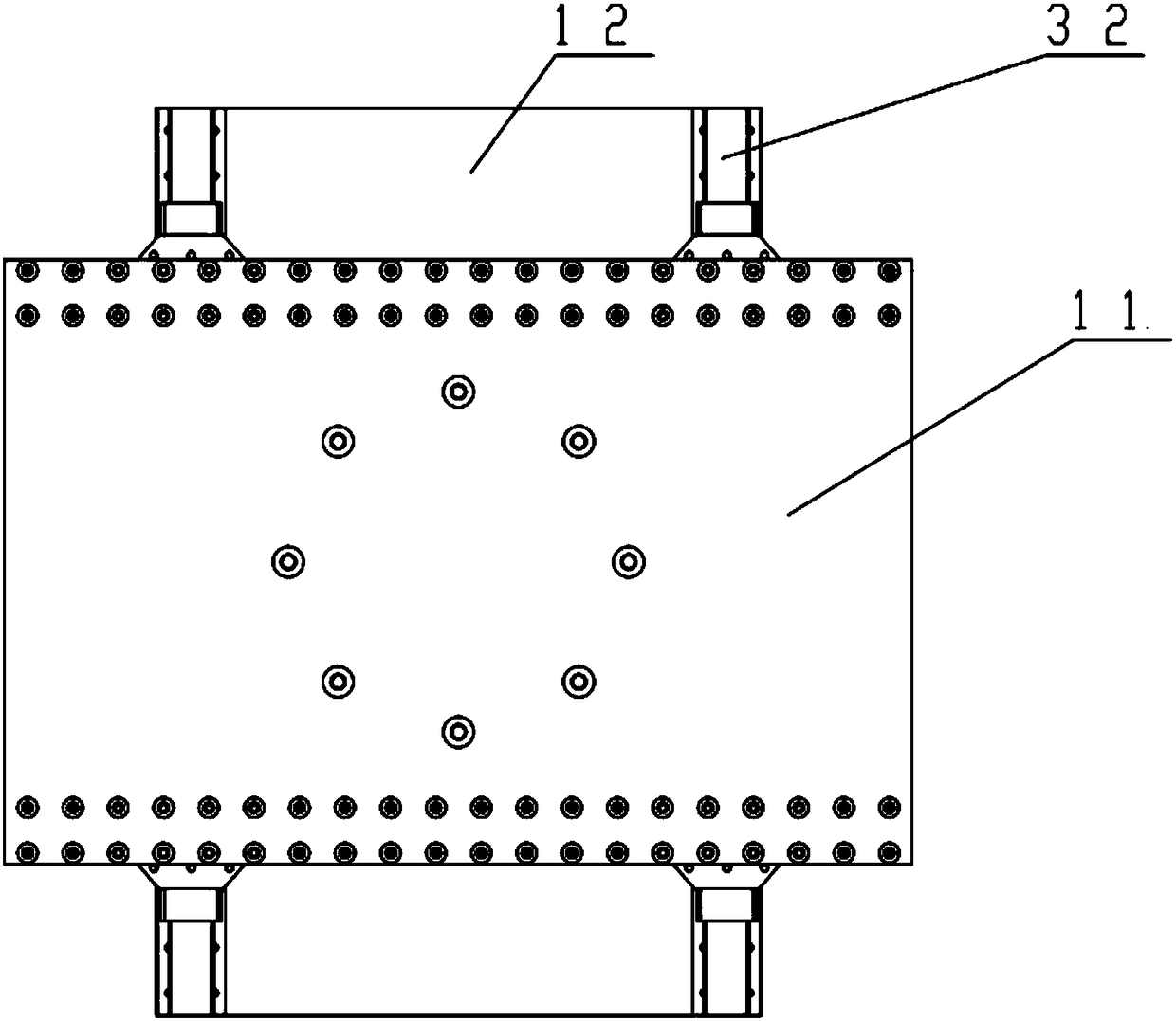

[0029] Such as figure 1 , figure 2 and image 3 A composite rail-type tension-proof rubber bearing is shown, including an upper flange plate 12 , a lower flange plate 11 , a tension-limiting device 4 , a transverse guide rail 31 , a longitudinal guide rail 32 and a vibration-isolation rubber bearing 2 . The shock-isolation rubber bearing is type I or type II, and the upper and lower flange plates are rectangular and perpendicular to each other. There are two transverse guide rails 31 and two longitudinal guide rails 32, which are in the shape of a dovetail groove. The two ends are sealed by welding to limit the chute from sliding out of the guide rail. Each is parallelly fixed to the edge of the inner surface of the lower flange plate 11 and the upper flange plate 12 by bolts, and the height of the bolts does not exceed the thickness of the flange plate. The tension limiting device 4 includes an upper connection part 43 , a limit box 42 and a lower connection part 41 . T...

Embodiment 2

[0031] Such as Figure 4 As shown, the difference between it and Embodiment 1 is that the shock-absorbing rubber bearing is Type II, the tensile limiting device 4 is placed upside down, and the limiting box 42 is circular.

[0032] In daily use, the friction between the upper and lower connecting parts and the guide rail can achieve a certain wind load resistance effect. When the earthquake comes, the upper and lower connecting parts of the limit device slide along the longitudinal and transverse guide rails respectively, without affecting the vibration isolation rubber support. The horizontal isolation effect of the seat, if the vertical earthquake is obvious, the limit box 42 can play the role of vertical tension limit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com