Halogen-free copolymer-type flame-retarding polyamide 66 and preparation method thereof

A flame-retardant polyamide, copolymerization technology, applied in the field of halogen-free copolymerization flame-retardant polyamide 66 and its preparation, can solve the problem of loss of material application performance, branching, reticulation, inability to form long-chain polymers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation of the halogen-free copolymerized flame-retardant polyamide 66 of the present invention is carried out according to the following steps:

[0022] (1) Preparation of the flame retardant organic salt solution: the organophosphorus flame retardant and the hexamethylenediamine solution with a concentration of 25 to 35wt.% are mixed to react to generate the flame retardant organic salt solution; The molar ratio of amines is 1:1.

[0023] (2) Pre-amidation reaction of hexamethylenediamine and adipic acid: mix hexamethylenediamine and adipic acid in the polymerization tank at a molar ratio of 1:1, control the pressure in the polymerization tank to 1.75-2.0MPa, and the temperature to 210- At 250°C, under this condition, hexamethylenediamine and adipic acid undergo a pre-amidation reaction, and the reaction time is 2-3 hours to obtain polyamide 66.

[0024] (3) After the step (2) pre-amidation reaction, the pressure in the polymerization tank is reduced to norma...

Embodiment 1

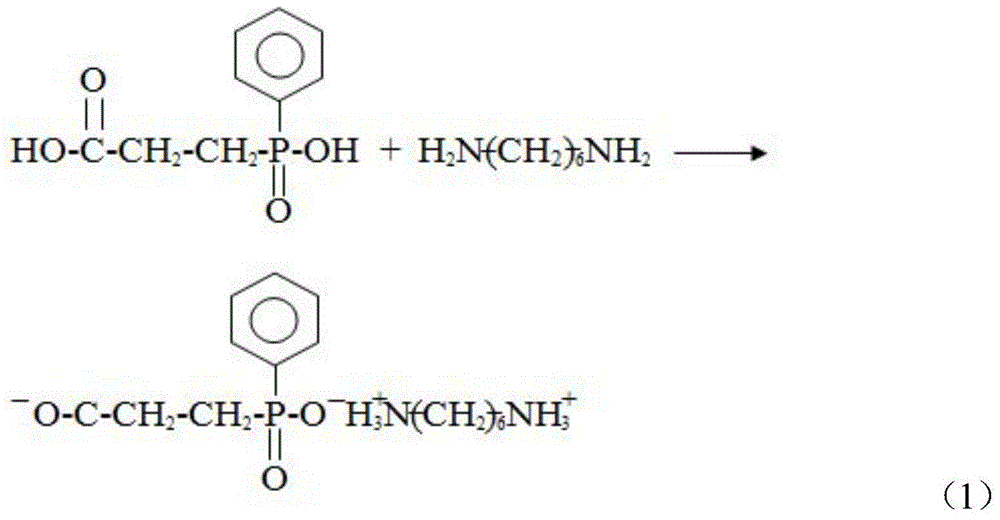

[0026] 1, get CEPPA3kg, hexamethylenediamine 0.81kg, be mixed with the flame retardant organic salt solution of concentration 60wt% (according to the amount calculation of corresponding CEPPA), pH value 7.5, reaction formula is as follows formula (1):

[0027]

[0028] 2. Add 200kg of nylon 66 (1:1 molar ratio of hexamethylenediamine to adipic acid) salt solution in a 300L polymerization kettle, the concentration is 50wt.%, the pressure is 1.75MPa, the temperature is 250°C, and the pre-amidation reaction is completed after 150min , to obtain polyamide 66.

[0029] 3. After the pressure of the polymerization tank where the reaction in step 2 is completed is reduced to -0.05MPa, inject the flame retardant organic salt solution prepared in step 1 into it. At a temperature of 284°C, the polymerization reaction is completed after 30 minutes to obtain halogen-free copolymerization Type flame-retardant polyamide 66 polymer material (slice), the reaction formula is as follows (2): ...

Embodiment 2

[0036] 1, get DDP4.5kg, hexamethylenediamine 1.5kg, be mixed with concentration 60wt% (according to the amount calculation of corresponding DDP), the flame retardant organic salt solution that pH value is 7.1, reaction formula is as follows formula (3):

[0037]

[0038]2. Add 200kg of nylon 66 salt solution to the 300L polymerization kettle, nylon 66 (1:1 molar ratio of hexamethylenediamine adipic acid) salt solution, the concentration is 50wt.%. Amidation reaction to obtain polyamide 66.

[0039] 3. After the pressure of the polymerization tank that completed the reaction in step 2 was reduced to -0.05MPa, inject the flame retardant organic salt solution prepared in step 1 into it. At a temperature of 284°C, the polymerization reaction was completed after 30 minutes to obtain halogen-free copolymerization Type flame-retardant polyamide 66 polymer material (slice), the reaction formula is as follows (4):

[0040]

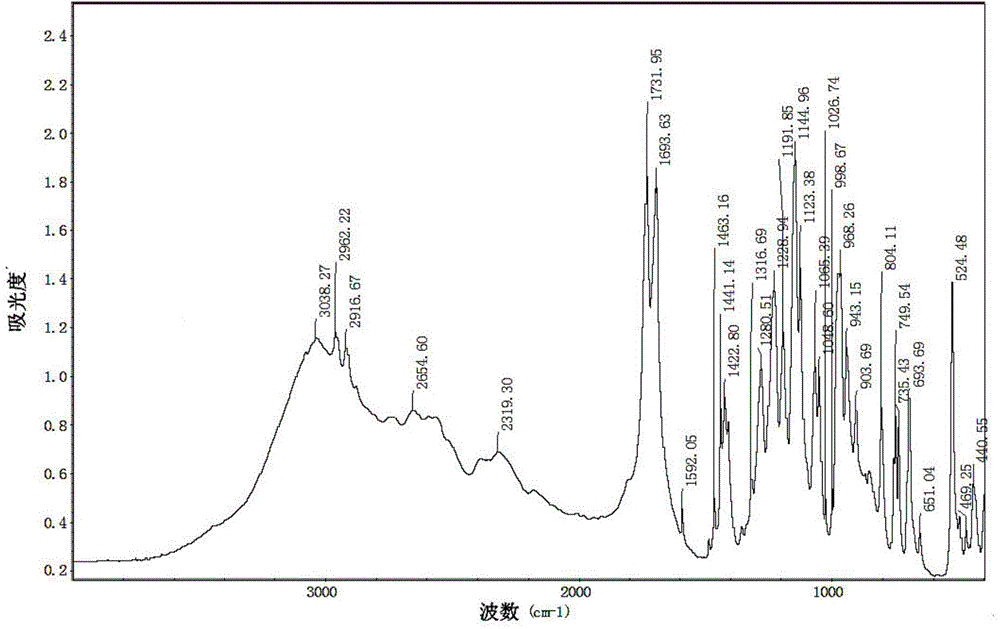

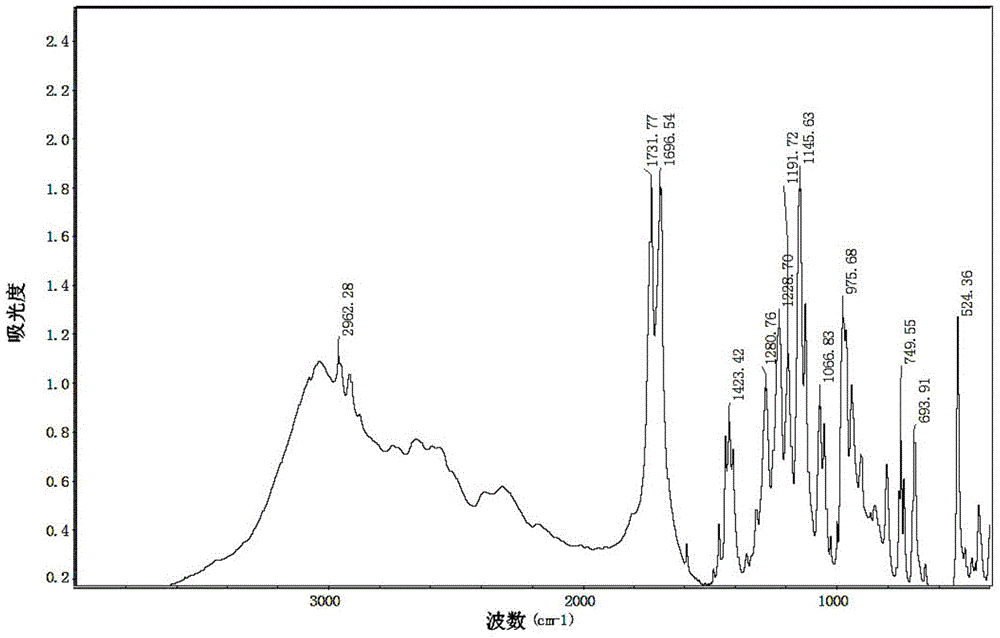

[0041] The flame retardant polyamide 66 infrared absor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com