Combined-production vehicle special for mining coal sand

A vehicle and coal sand technology, which is applied in the field of co-production vehicles for coal sand mining, can solve the problems of low space utilization, inability to drag, poor safety, etc., to reduce production and manufacturing costs, solve the problem of frequent transfers, and facilitate disassembly quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

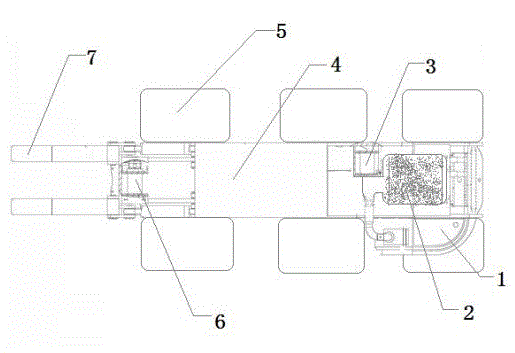

[0012] This embodiment provides a special co-production vehicle for coal sand mining, which is characterized in that: the special co-production vehicle for coal sand mining includes a fuel tank (1), a driving machine (2), a first winch (3), a frame (4), traveling device (5), second winch (6), fork (7);

[0013] Among them: the fuel tank (1) is installed on the body of the frame (4), the fuel tank (1) is connected to the driving machine (2) through pipelines, the traveling device (5) is installed on both sides of the body of the frame (4), and the fork (7) Hinged to one end of the frame (4) body, the first winch (3) is installed on the fork (7), the second winch (6) is installed at the rear end of the frame (4) body, the driving machine ( 2) It is used to drive the action of the fork (7), the traveling device (5), the first winch (3) and the second winch (6).

[0014] The walking device (5) is provided with 3 groups.

Embodiment 2

[0016] A special co-production vehicle for coal sand mining, characterized in that: the special co-production vehicle for coal sand mining includes a fuel tank (1), a driving machine (2), a first winch (3), a vehicle frame (4), a walking Device (5), second winch (6), fork (7);

[0017] Among them: the fuel tank (1) is installed on the body of the frame (4), the fuel tank (1) is connected to the driving machine (2) through pipelines, the traveling device (5) is installed on both sides of the body of the frame (4), and the fork (7) Hinged to one end of the frame (4) body, the first winch (3) is installed on the fork (7), the second winch (6) is installed at the rear end of the frame (4) body, the driving machine ( 2) It is used to drive the action of the fork (7), the traveling device (5), the first winch (3) and the second winch (6).

[0018] The walking device (5) is provided with 2 groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com