Self-weighing hydraulic baler with rotary bales

A weighing mechanism and box packing technology, which is applied in the directions of automatic packaging control, packaging, and wrapping objects, etc., can solve the problems of high labor intensity and low working efficiency of mobile balers, so as to reduce labor intensity, solve high labor intensity, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

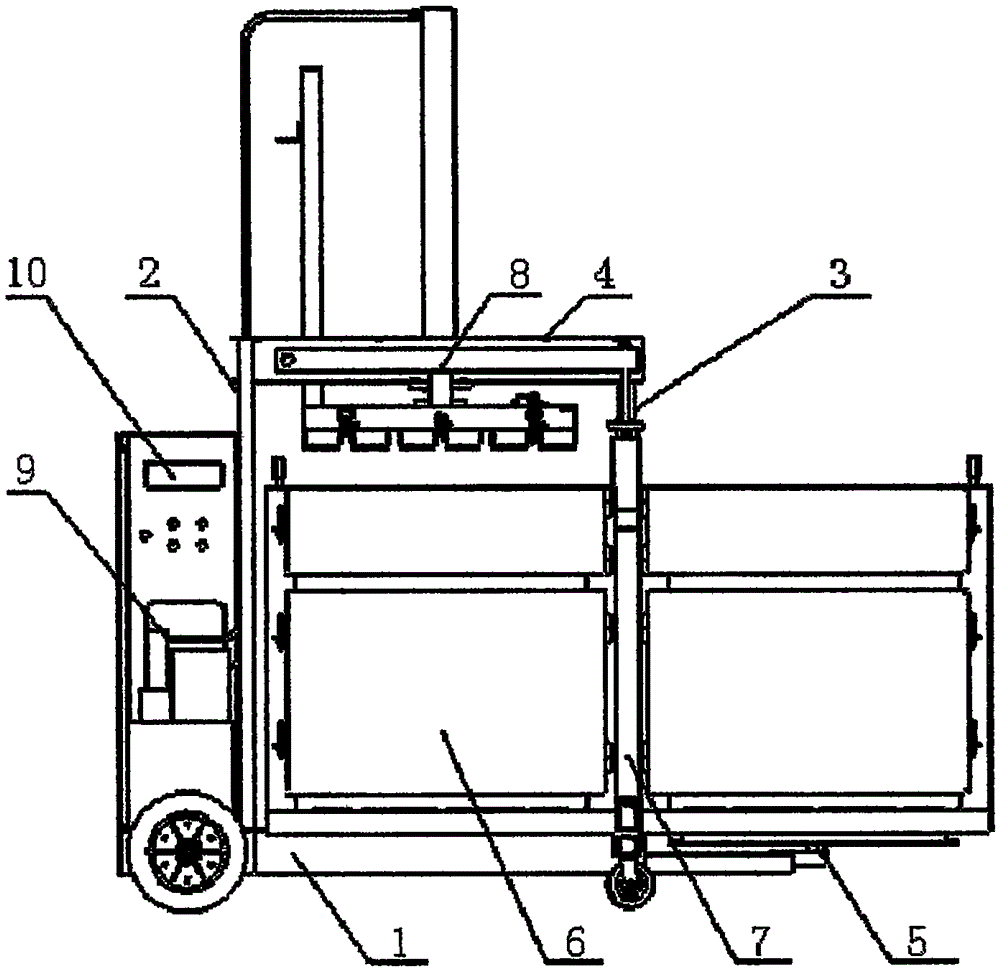

[0021] A rotary box-type self-weighing hydraulic baler, which is mainly composed of a mobile chassis 1, a frame column 2, a rotating column 3, an upper frame 4, a weighing mechanism 5, a rotary box 6, a box-turning mechanism 7, and a box-lifting mechanism 8. A hydraulic system 9 and an electrical system 10, characterized in that:

[0022]1. A moving wheel is installed under the mobile chassis 1, so that the baler can move back and forth conveniently. The mobile wheel can be a universal wheel or not a universal wheel according to the needs; a positioning device is provided on the mobile chassis. After the rotating bag box 6 falls, it can be accurately positioned on the mobile chassis 1; the upper frame 4 is connected with the mobile chassis 1 through the frame column 2 and the rotating column 3; the weighing mechanism 5 is installed on the mobile chassis 1, and it Located on the outside of the rotating column 3, it is mainly composed of a lower weighing frame 11, an upper weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com