On-line continuous sectioning, straightening and sawing in pairs to produce elevator guide rail finishing equipment and method

An elevator guide rail and paired technology, which is applied in the finishing field of paired production of hot-rolled elevator guide rail blanks, can solve the problems of poor working conditions for workers, low product productivity, and high labor intensity, and achieve good labor conditions and high production efficiency for workers. The effect of high and high level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific examples, so that those skilled in the art can better understand and implement the present disclosure, but the examples given are not intended to limit the present invention.

[0026] In this embodiment, the main processing object of the invention is a fixed-length double-size T89 rolled into a pair of elevator guide rails, and the processing capacity of this finishing process is 60t / h.

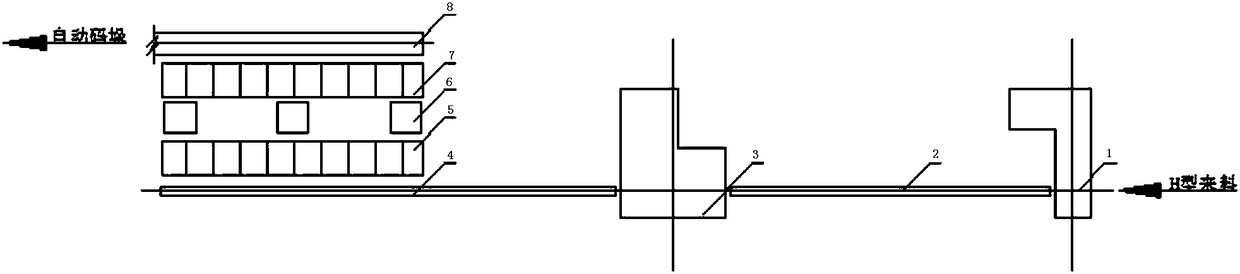

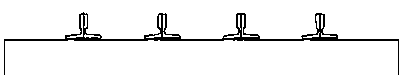

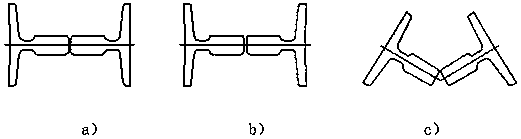

[0027] Such as Figure 1 to Figure 8 As shown, it mainly consists of splitting machine 1, rear roller table of splitting machine 2, double groove straightening machine 3, front and rear roller table for straightening 4, row bench before sawing (including input and output flat supporting steel shifting machine) 5, saw Cutting unit (including special fixtures) 6, turning steel table after sawing (including input and output flat support steel shifting machines) 7, stacking inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com