Multi-functional bending device

A bending device and a multi-functional technology, applied in the field of multi-functional bending devices, can solve the problems that it is difficult to accurately locate the size of the bending edge, difficult to ensure the flatness of the workpiece, and the level of skilled workers, and reduce the skill requirements of employees. , Eliminate the leveling process, the effect of high product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

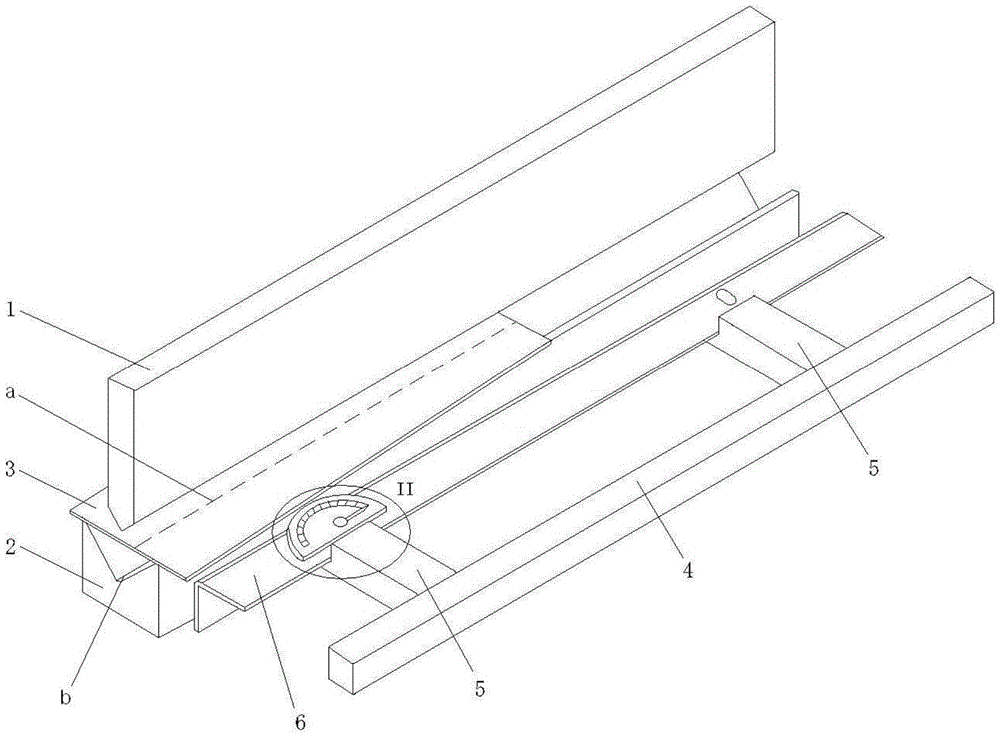

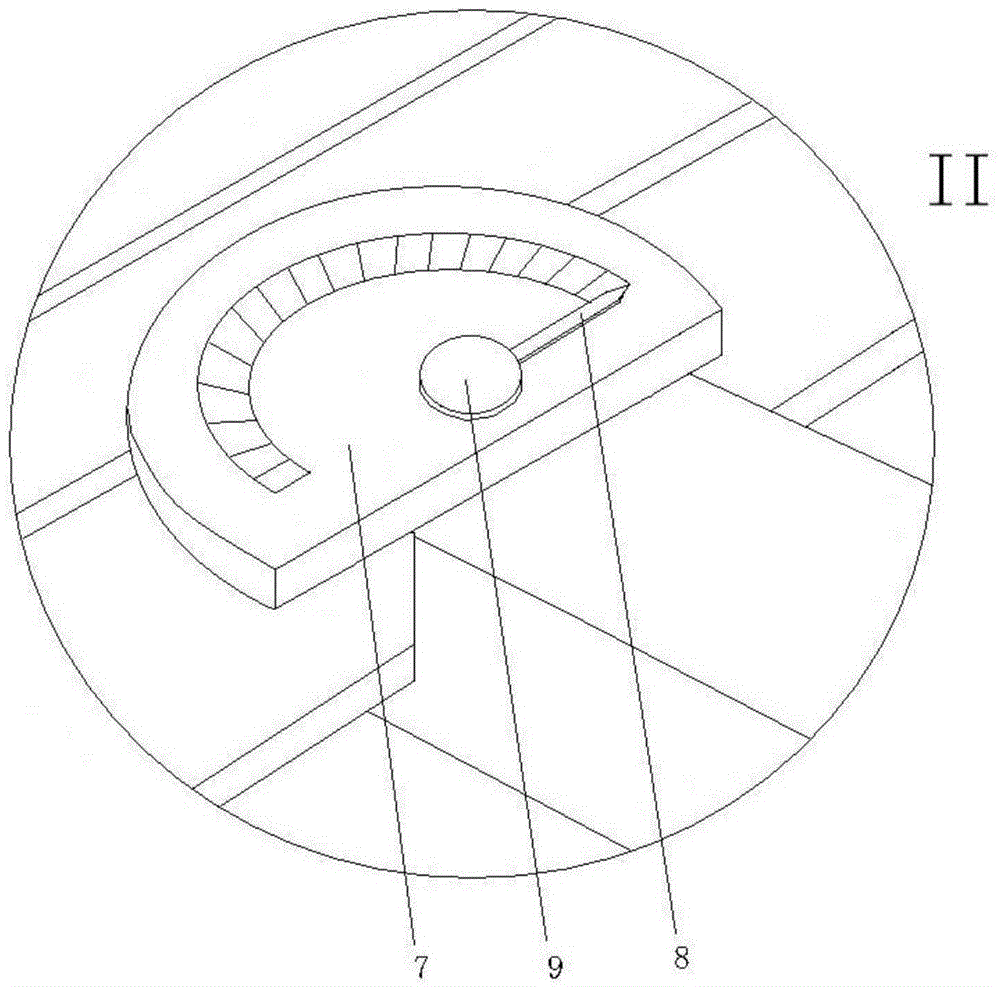

[0023] Such as figure 1 As shown, a multifunctional bending device includes a bending machine blade 1 and a bending machine lower die 2, a workpiece 3 is placed between the bending machine blade 1 and the bending machine lower die 2, and also includes a bending stop plate mechanism and angle measuring instrument, the bending baffle mechanism includes a baffle crossbeam 4, two stop blocks 5 and a bending baffle 6, the bending baffle 6 is respectively connected to the two stop blocks 5 through nuts and bolts 9, It is located on one side of the lower die 2 of the bending machine and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com