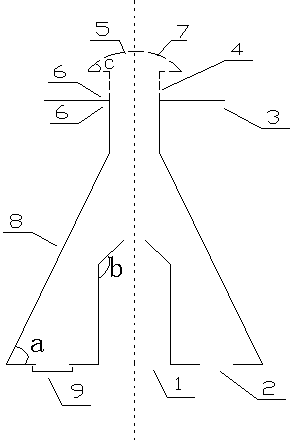

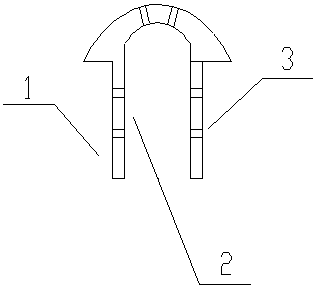

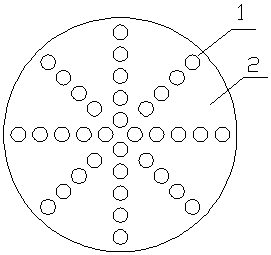

A gas-liquid distribution plate for an upflow reactor

A gas-liquid distribution and reactor technology, applied in chemical instruments and methods, treatment with moving solid particles, chemical/physical processes, etc., can solve problems such as reducing the service life and operation cycle of catalysts, damaging catalyst performance, and affecting catalyst effects , to achieve the effect of improving internal utilization, increasing processing capacity, and saving reactor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Using the gas-liquid distribution plate of the present invention to carry out the hydrogenation reaction of fluidized bed residual oil, the reaction conditions are: reaction temperature 396°C, reaction pressure 15MPa, hydrogen-oil ratio 500:1, volume space velocity 0.4h -1 . The properties of the residual oil are shown in Table 1, and the evaluation results are shown in Table 2. The reactor is filled with FZC-24 produced by Fushun Petrochemical Research Institute.

Embodiment 2

[0042] Using the gas-liquid distribution plate of the present invention to carry out the hydrogenation reaction of fluidized bed residue, the reaction conditions are: reaction temperature 396 ° C, reaction pressure 15 MPa, hydrogen-oil ratio 500:1, volume space velocity 0.4 h -1 . The properties of the residual oil are shown in Table 1, and the evaluation results are shown in Table 2. The reactor is filled with FZC-24 produced by Fushun Petrochemical Research Institute. At the same time, the gas-liquid distributor of the present invention (constituted as FZC-11) is also installed in the inlet pipeline at the bottom of the reactor.

Embodiment 3

[0044] The gas-liquid distributor of the present invention is used to carry out double fluidized bed reactors connected in series to carry out hydrogenation reaction of residual oil. The reaction conditions are: reaction temperature 396°C / 396°C, reaction pressure 15MPa, hydrogen-oil ratio 500:1, total volume space velocity 0.2 h -1 . The properties of the residual oil are shown in Table 1, and the evaluation results are shown in Table 2. FZC-24 and FZC-34 produced by Fushun Petrochemical Research Institute are respectively filled inside the first and second reverse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com