Production apparatus and usage method of diesel vehicle exhaust treatment fluid

A technology for tail gas treatment and production equipment, which is applied in the direction of separation methods, chemical instruments and methods, mixers, etc., can solve the problems of high product transportation and storage costs, high water content, etc., achieve reduced transportation and storage costs, small investment, and avoid The effect of reduced product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

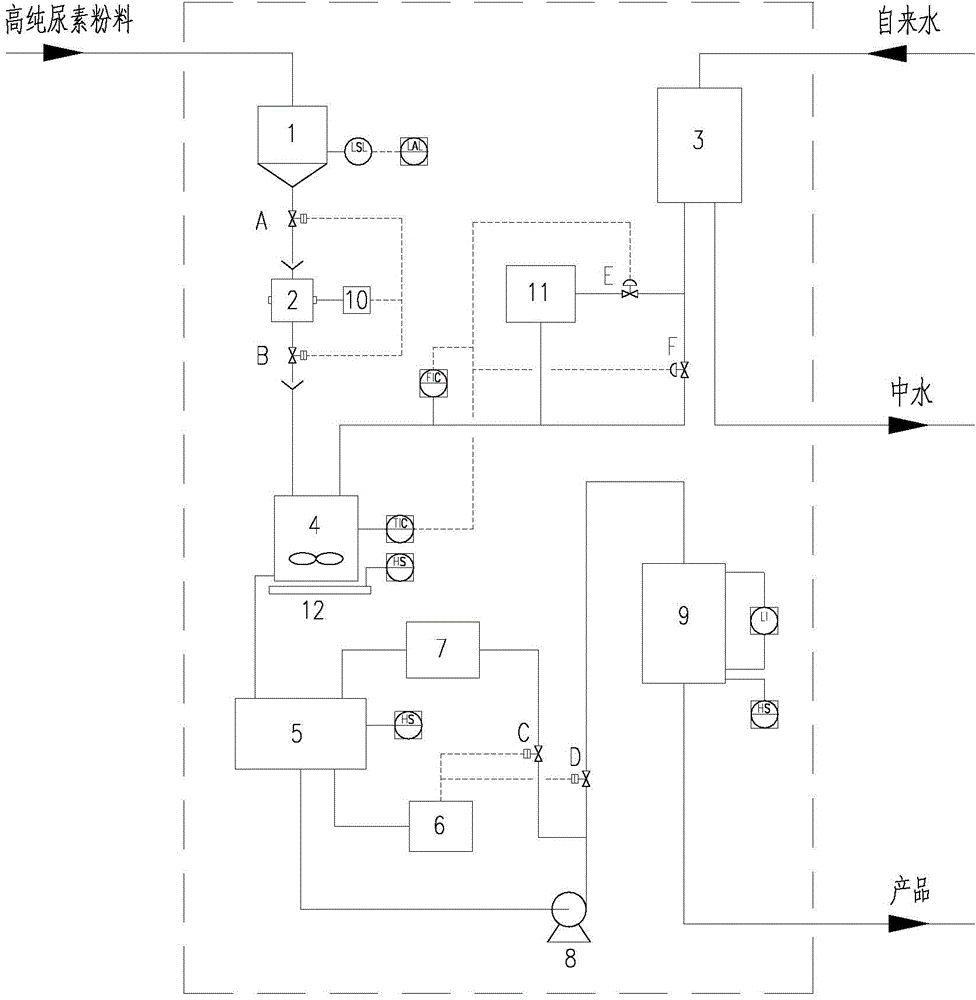

[0023] The preparation of the diesel vehicle tail gas treatment liquid of the present invention is to dissolve high-purity urea in ultra-pure water to prepare a urea aqueous solution with a mass concentration of 31.8-33.3%, and perform intermittent operations.

[0024] After the municipal tap water is purified into ultrapure water by the ultrapure water device 3, it is divided into two streams, one of which enters the solar heating equipment 11 through the regulating valve E to heat up, and the other directly enters the preparation kettle 4 through the regulating valve F, and the preparation kettle 4 (volume 40L) is equipped with temperature control, when the temperature of the ultrapure water in the preparation kettle 4 is higher than 30°C, reduce the opening of the regulating valve E and increase the opening of the regulating valve F. When the quality of the ultrapure water added in each batch is 26kg according to the statistics of the flow meter, the regulating valves E and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com