Determination of Elastic Modulus and Preparation Method of Personalized Posterior Pedicle Screw System

A pedicle screw and elastic modulus technology, which can be used in fixators, internal fixators, computer-aided planning/modeling, etc., can solve problems such as the mismatch of spine elastic modulus, and achieve uniform and reasonable stress distribution of rods. Good, compliant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

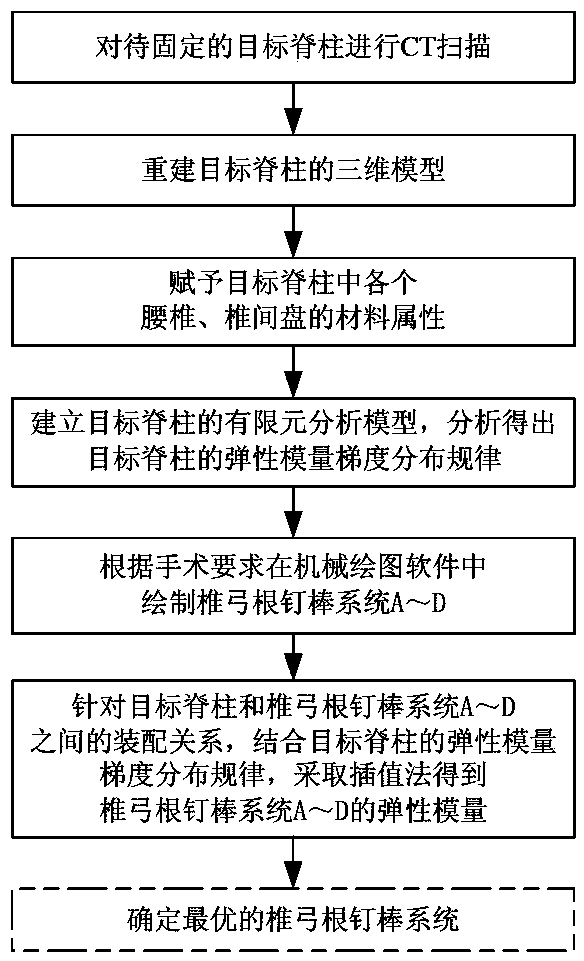

[0028] The following is a special case of four different sizes of pedicle screw-rod systems A, B, C, and D of the target spine to be fixed. First, the determination of the elastic modulus of the pedicle screw-rod system A is taken as an example to personalize the present invention. The method for determining the elastic modulus of the posterior spinal pedicle screw-rod system is further described in detail.

[0029] Such as figure 1 As shown, the steps of the method for determining the elastic modulus of the personalized posterior spinal pedicle screw-rod system in this embodiment include:

[0030] 1) CT scanning is performed on the target spine to be fixed, and the three-dimensional model of the target spine is reconstructed using the CT scan data using the medical image control system, such as figure 2 As shown, its local enlarged structure is shown as image 3 As shown; in this embodiment, the medical image control system specifically adopts the Mimics medical image cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com