Magnetic induction motor

A magnetic induction type, electric motor technology, applied in the direction of electric components, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., to achieve the effect of suppressing cracks and avoiding contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

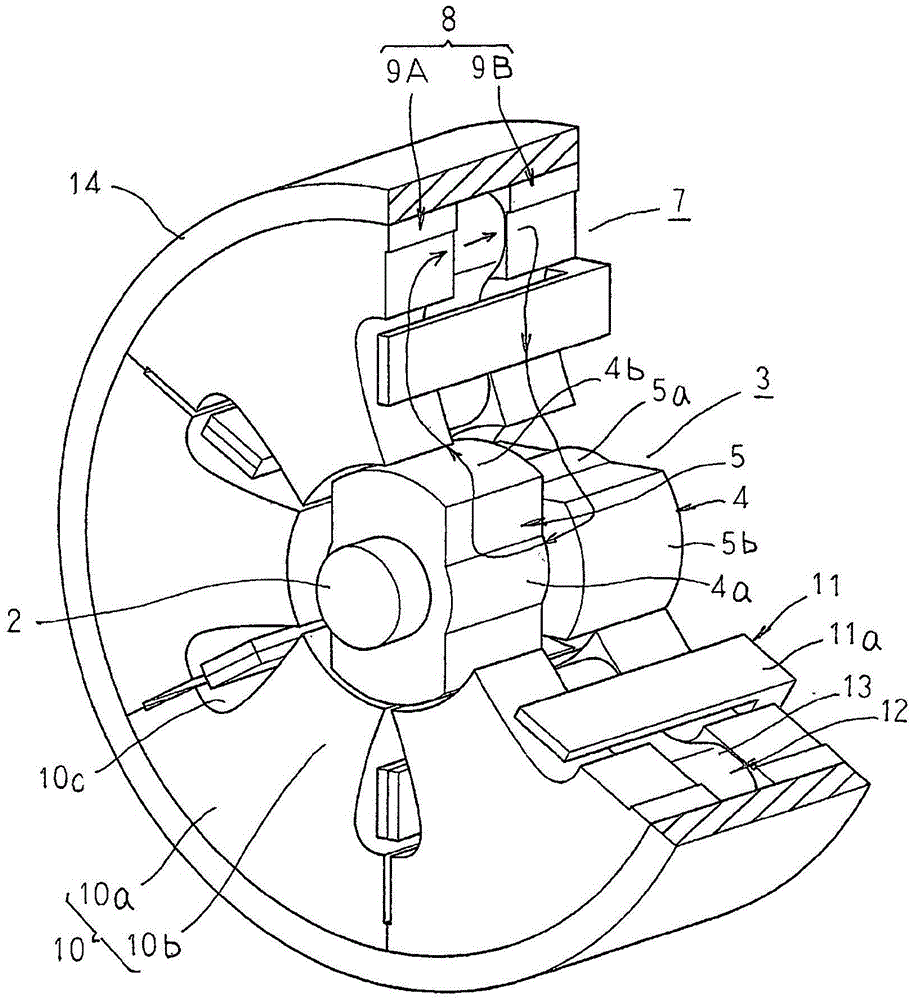

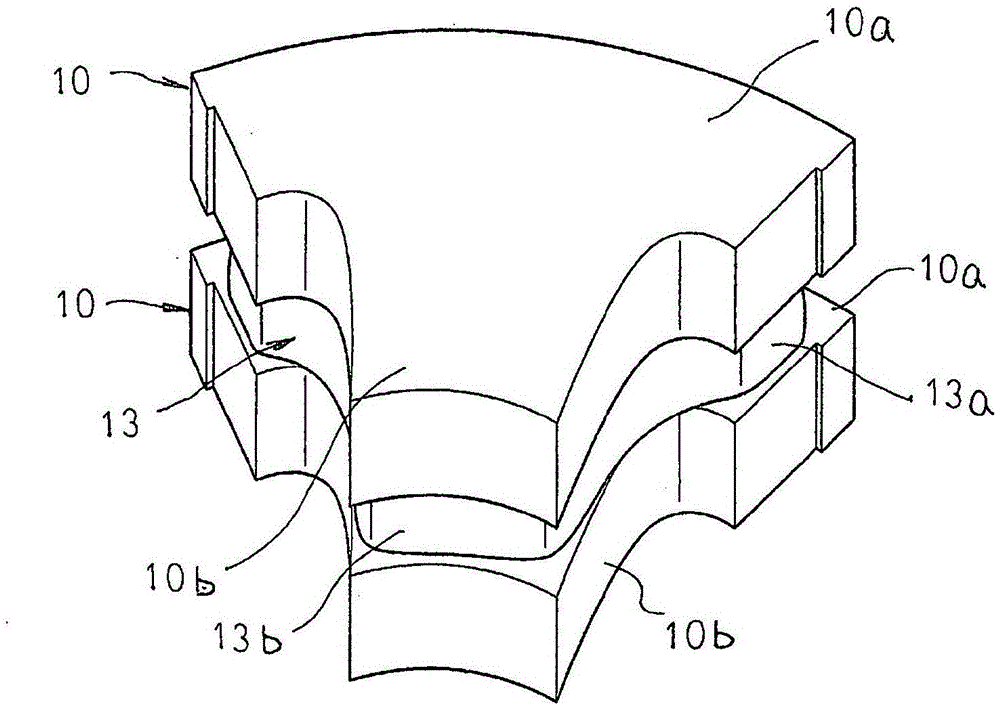

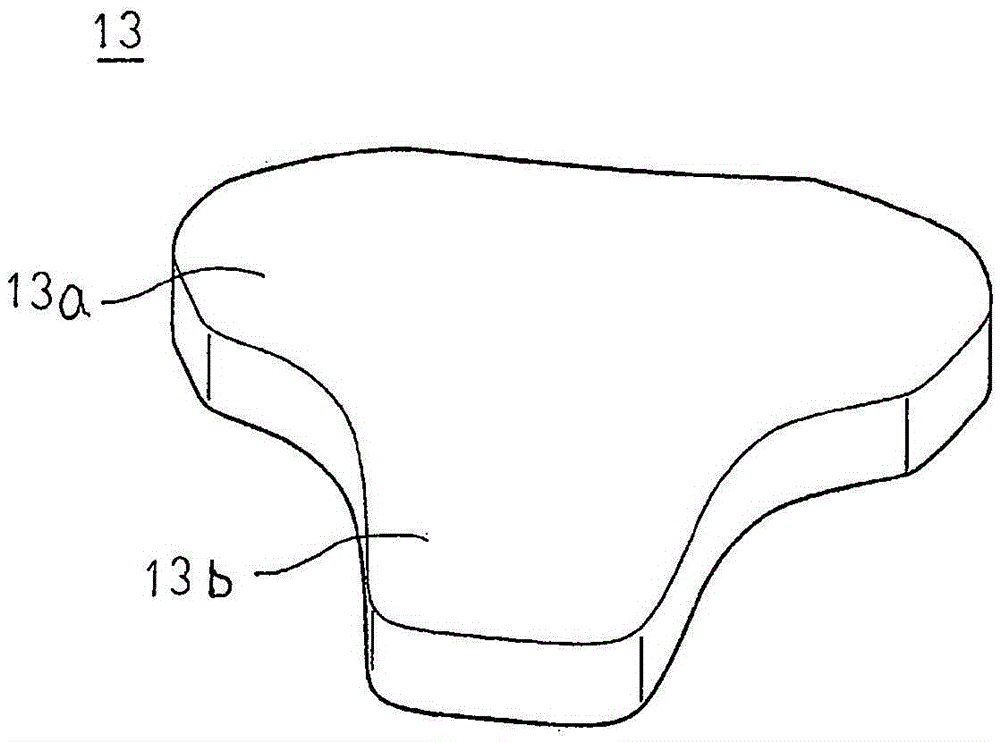

[0026] figure 1 is a partially cutaway perspective view showing the main structure of the magnetic induction motor according to Embodiment 1 of the present invention, figure 2 It is a perspective view showing core block pairs aligned in the axial direction in the magnetic induction motor according to Embodiment 1 of the present invention, image 3 It is a perspective view showing a magnet block in the magnetic induction motor according to Embodiment 1 of the present invention.

[0027] exist figure 1 Among them, the magnetic induction motor 1 includes a rotor 3 coaxially fixed to a rotating shaft 2 made of a block-shaped magnetic body such as iron, and a stator coil 11 serving as a drive coil for torque generation is wound around the rotor 3 and arranged around the rotor 3. A stator 7 comprising a stator core 8 , a permanent magnet 12 serving as an excitation unit, and a case 14 for accommodating the rotor 3 , the stator 7 , and the permanent magnet 12 are provided.

[002...

Embodiment approach 2

[0049] Figure 4 It is a perspective view showing a state in which three core block pairs are arranged in the magnetic induction motor according to Embodiment 2 of the present invention, Figure 5 It is a perspective view of adjacent core block pairs in the magnetic induction motor according to Embodiment 2 of the present invention viewed from the inside in the radial direction, Figure 6 It is a schematic view of adjacent core block pairs in the magnetic induction motor according to Embodiment 2 of the present invention viewed from radially inside. In addition, in Figure 4 In , for convenience, the concentrated winding coils are omitted.

[0050] When the core blocks 10 are arranged in an annular shape so that the side surfaces of the core backs 10 a face each other, the side surfaces of the core backs 10 a do not completely contact each other but partially contact each other. In this embodiment 2, as Figure 4 As shown, only the outer peripheral portions of the side sur...

Embodiment approach 3

[0057] Figure 7 It is a schematic view of adjacent core block pairs in the magnetic induction motor according to Embodiment 3 of the present invention viewed from radially inside.

[0058] exist Figure 7 Among them, the core block 20 is divided into two in the axial direction into a first divided core block 21 and a second divided core block 22 . Like the core block 10, the first split core block 21 includes an arc-shaped core back portion 21a and teeth (not shown) protruding radially inward from the center position in the circumferential direction of the inner peripheral surface of the core back portion 21a. The second split core block 22 includes an arc-shaped core back 22a, and teeth (not shown) protruding radially inward from a position displaced from a central position in the circumferential direction of the inner peripheral surface of the core back 22a to one side in the circumferential direction. . Here, the outer shapes of the core backs 21 a and 22 b of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com